设计简介

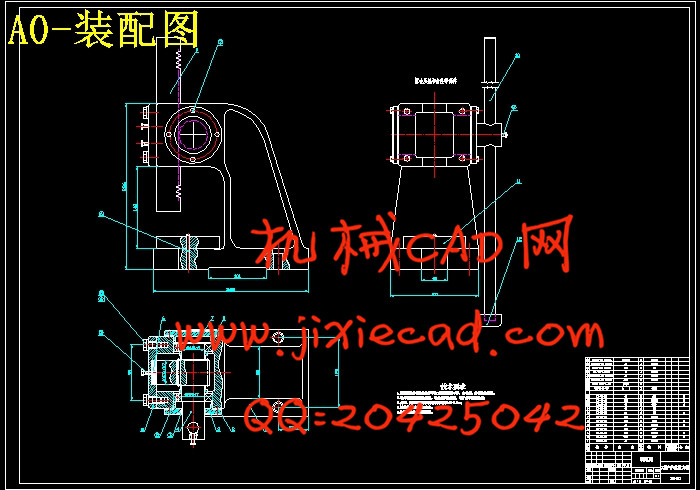

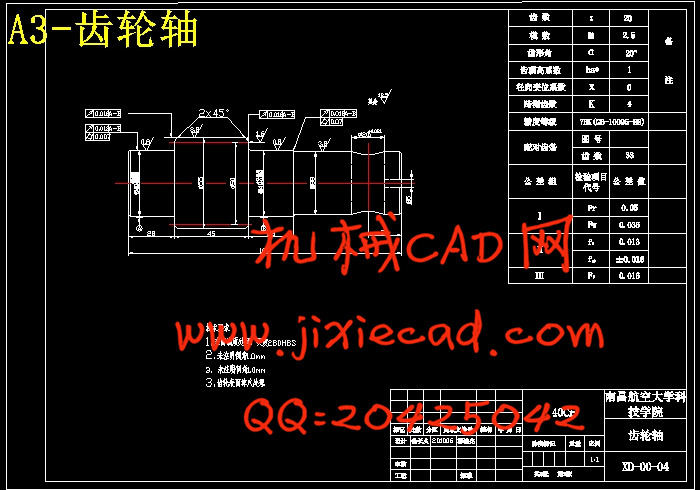

摘要: 本课题是刀杆手动压力机的设计,针对机械装置工作条件,设计符合实际工作要求的压力机。压力机的设计包括齿轮轴、齿条、箱体的设计和一些零部件的选用校核等。在设计过程中,根据任务书提供的压力机的长度、宽度、高度、行程等要求,完成压力机的总体设计。对压力机进行受力分析,完成齿轮的设计。由于压力机的机身结构紧凑,齿轮与轴连成一体,做成齿轮轴结构。在齿轮轴设计时候,完成选用轴承、拟定轴上的零件的装配方案、校核轴的强度要求等工作。完成齿轮轴结构的的设计后,就可以进一步确定与其啮合的齿条的尺寸,并设计齿条的工艺规程。齿条的工艺规程设计有两种方案,比较两种方案的优劣,选择合适的一种。轴承对压力机的工作发挥着重要的作用,应该校核其强度,设计其密封装置等。在以上各项工作完成后,可以设计压力机机身(箱体)的设计和轴承端盖的设计。最后,还应进行成本校核,成本核算的实质是一种数据信息处理加工的转换过程,即将日常已发生的各种资金的耗费,按一定方法和程序,按照已经确定的成本核算对象或使用范围进行费用的汇集和分配的过程。成本校核的目的是为了在满足机械工作要求和加工精度的基础上,设计出最经济廉价产品。

关键词: 压力机 齿轮齿条机构 成本校核

Abstract:Holders of this issue is to manually press-style design, working conditions for mechanical devices, were designed to press the actual job requirements. The design of presses, including gear, rack, cabinet design and a number of components, such as the choice of checking. During the design process, according to mandate the provision of the Press book length, width, height, stroke and other requirements, the completion of the design press. Stress Analysis of Press to complete the design of gear. Completion of the structure of the design of gear, you can further complete the rack design, and design Process rack. Process design of the rack, there are two programs: one-piece small batch production and mass production. According to the actual situation of the workshop process to choose the appropriate line. As the press of the fuselage structure, connecting gear with the shaft, gear shaft into the structure. At the completion of the design of gear based on the complete selection of bearings, shaft to complete the design, preparation of parts of the assembly axis program, check-axis intensity of the work requirements. Bearing on the work of press plays an important role, we should check its strength, the design of the sealing devices. In the above work is completed, press frame can be designed (box) cover the design and the design of bearings. Finally, the cost of checking should be carried out, the real cost of information processing is a data processing conversion process. The purpose of the cost of checking is to meet the mechanical requirements and processing accuracy, based on the most economical to design low-cost products.

Keyword: forcing press rack and pinion agencies check the cost

关键词: 压力机 齿轮齿条机构 成本校核

Abstract:Holders of this issue is to manually press-style design, working conditions for mechanical devices, were designed to press the actual job requirements. The design of presses, including gear, rack, cabinet design and a number of components, such as the choice of checking. During the design process, according to mandate the provision of the Press book length, width, height, stroke and other requirements, the completion of the design press. Stress Analysis of Press to complete the design of gear. Completion of the structure of the design of gear, you can further complete the rack design, and design Process rack. Process design of the rack, there are two programs: one-piece small batch production and mass production. According to the actual situation of the workshop process to choose the appropriate line. As the press of the fuselage structure, connecting gear with the shaft, gear shaft into the structure. At the completion of the design of gear based on the complete selection of bearings, shaft to complete the design, preparation of parts of the assembly axis program, check-axis intensity of the work requirements. Bearing on the work of press plays an important role, we should check its strength, the design of the sealing devices. In the above work is completed, press frame can be designed (box) cover the design and the design of bearings. Finally, the cost of checking should be carried out, the real cost of information processing is a data processing conversion process. The purpose of the cost of checking is to meet the mechanical requirements and processing accuracy, based on the most economical to design low-cost products.

Keyword: forcing press rack and pinion agencies check the cost

目录

1 前言

1.1 课题研究的目的及意义 …………………………………………(1)

1.1.1 手动压力机的研究目的 ………………………………………(1)

1.1.2 手动压力机的研究意义 ………………………………………(1)

1.2 国内外研究现状 …………………………………………………(1)

1.3 本课题研究内容 …………………………………………………(2)

2 总体方案确定 ……………………………………………………(3)

3 齿轮的设计

3.1 选定齿轮类型、精度等级、材料和齿数 ………………………(4)

3.2 齿轮设计 …………………………………………………………(4)

3.2.1 按齿面接触强度设计 …………………………………………(4)

3.2.2 按齿根弯曲强度设计 …………………………………………(6)

3.3 齿轮的几何尺寸计算 ……………………………………………(7)

4 轴的设计

4.1 初步确定轴的最小直径大小 ……………………………………(10)

4.2 齿轮轴的结构设计 ………………………………………………(10)

4.3 轴的校核 …………………………………………………………(12)

4.3.1 按轴的扭矩强度条件校核 ……………………………………(13)

4.3.2 按弯扭合成强度条件校核 ……………………………………(14)

5 轴承的选用与布置

5.1 轴承的选用与校核 ………………………………………………(16)

5.2 滚动轴承的配置 …………………………………………………(17)

5.3 滚动轴承的润滑 …………………………………………………(17)

5.4 滚动轴承的密封装置 ……………………………………………(17)

6 压力机箱体及附件设计

6.1 箱体的结构设计 …………………………………………………(19)

6.2 轴承盖的设计 ……………………………………………………(19)

6.3 手柄的设计与强度校核 …………………………………………(20)

7 齿条和其工艺规程的设计

7.1 齿条参数的确定 …………………………………………………(21)

7.2 齿条工艺设计分析 ………………………………………………(22)

7.2.1 确定毛胚制造方法 ……………………………………………(22)

7.2.2 各平面加工方法确定 …………………………………………(23)

7.2.3 各平面加工余量确定 …………………………………………(23)

7.2.4 绘制毛胚图 ……………………………………………………(24)

7.2.5 背吃刀量确定 …………………………………………………(24)

7.2.6 加工齿条刀具选择………………………………………………(25)

7.2.7 选择定位基准 …………………………………………………(25)

7.2.8 拟定零件加工工艺路线 ………………………………………(25)

8 成本核算

8.1 成本核算的概念和意义 …………………………………………(28)

8.2 产品生产成本项目 ………………………………………………(28)

8.3 生产成本的核算 …………………………………………………(28)

8.3.1 铸件的成本核算 ………………………………………………(29)

8.3.2 直接材料成本核算 ……………………………………………(29)

8.3.3 直接人工成本核算 ……………………………………………(30)

8.3.4 制造成本核算 …………………………………………………(30)

8.3.5 压力机成本价格总额 …………………………………………(30)

参考文献…………………………………………………………………(31)

致谢 ………………………………………………………………………(32)