设计简介

摘 要

摘要:曲柄连杆是若干构件用低副连接成的机构。曲柄连杆机构中的构件大都可以表示为杆状,故亦称其为杆.由于低副是圆柱面或平面接触,使得平面连杆机构具有制造容易、运动副中压强和磨损较小、便于润滑等优点,因此平面连杆机构广泛用于天各种机械及仪器中。但是,这种机构运动副磨损后会形成间隙,当构件数目较多时,会使从动件产生较大的运动累积误差,不容易精确地实现复杂的运动规律。关键词: 曲柄 连杆。

Abstract

Crank connecting bar is a mechanism that severial mechanical components are connected by low counter gear. The mechanical components of crank connecting bar can normally be expressed as rodlike forms, so we can also called it “bar”. Due to low counter gear indicats a cylindrical surface contact or a plane surface contact,planar linkage mechanisms has a numbers of advantages such as easy manufacture, relatively small pressure and abrasion of kinematic pair, and easier lubrication, so which has been widely used in various machinery and apparatus. However, a gap will be formed after this kind of mechanism of kinermatic pair is fretted away. Followers will lead to accumulated error of movement when there is a relative large number of mechanical components, so which is not easy to precisely realize the complicated law of motion.Key words: crank connecting bar

目录

第一章、 绪论 - 1 -

1.1 选题的目的和意义 - 2 -

1.2 国内外的研究现状 - 3 -

1.3 设计研究的主要内容 - 5-

第二章、曲柄连杆机构的整体设计概念 - 6 -

2.1设计机械整体时应满足的要求: -6 -

2.2、标准化、系列化、通用化: - 6-

2.3、结构设计: - 7-

第三章、 曲柄连杆机构基本知识 - 7 -

3.1 曲柄连杆中部分名词 - 7 -

3.2 曲柄连杆机构的自由度与约束 - 8 -

3.3、 曲柄连杆机构的运动分析 - 13-

第四章、曲柄连杆机构的设计与计算 - 15 -

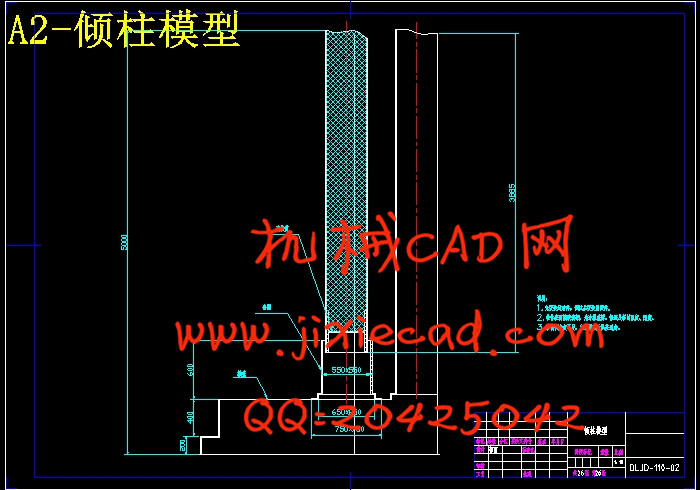

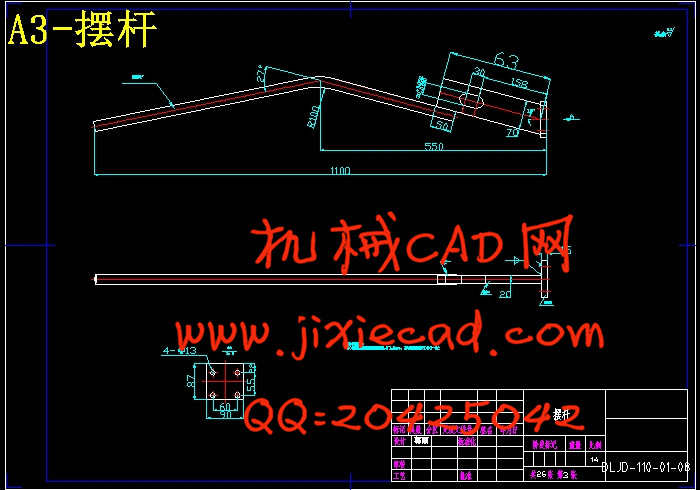

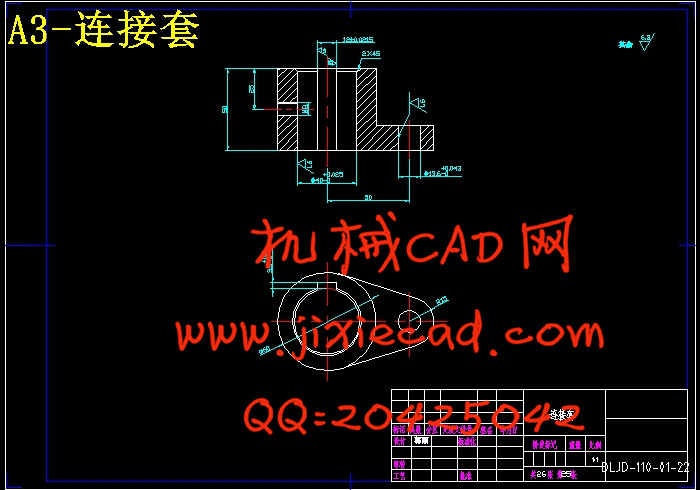

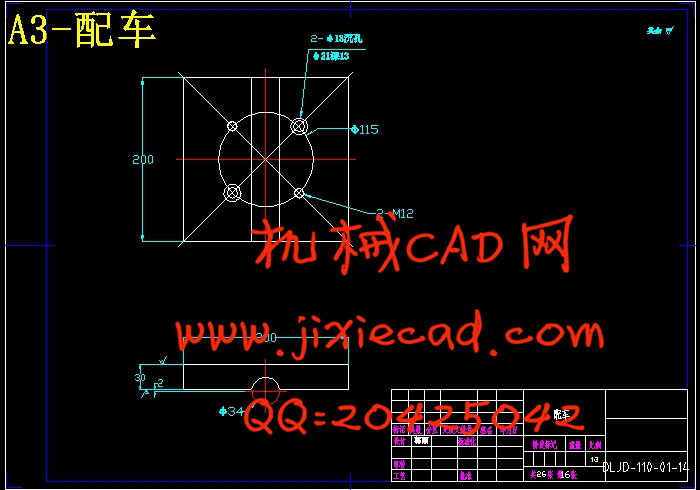

4.1 曲柄连杆机构的设计 - 15 -

4.2 曲柄连杆机构的计算 - 19 -

4.3 连杆螺栓的设计 - 30-

第五章、 曲柄连杆机构的应用 - 32 -

第六章 - 34 -

6.1 机构 - 34 -

6.2维护与保养 - 35 -

6.3 注意事项 - 35 -

结论 - 36 -

参 考 文 献 - 37 -

致谢 - 38 -