设计简介

摘 要

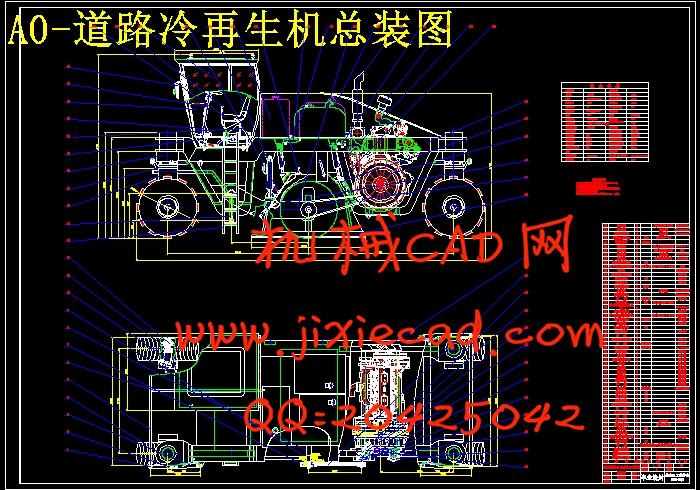

道路就地冷再生机是在铣刨机基础上经过优化和改进的一种集合了翻挖、回收、破碎、筛分并与新料结合快速完成旧沥青路面的再生,使之能够满足一定的路用性能并用其重新铺筑路面的现代化新型机械。本设计为轮式就地冷再生机,具有铣刨和拌和功能,可双向作业,采用全液压四轮驱动,液压转向与制动。就地冷再生机为我国现存道路的维修养护和延长现存道路的服务年限提供了一种更经济、更合理和更高回报的道路建设和维修养护施工工艺及施工设备。

本文参考现有冷再生设备,对道路就地冷再生机的总体设计方案, 总体参数及装置零件的选择与计算,道路就地冷再生机的各种性能进行了分析,

关键词:就地冷再生机;总体设计;性能分析;参数计算;

ABSTRACT

Crank Press is a fundamental equipment, which makes a mould,and it is extensively applied in the production of industry. The crank press which was designed is mainly used for molding which be unable to bear a heavy pressure,then starting the engine of crank press to complete the bend forming process when after the crank press fixed. The working mechanism is supported by the linkage of crank which is changed the motor spinning activity into moving straight line (back and forth) through by crank, linkage and slider. The process of die spotting is causing by upper die which is shifted by slider. When the crank spines one time, the slider returns (back and forth) once, then finished one product. This design is mainly attend to measure and design the organization of mould; the choosing of pressure machine and electric motor; the design and measure of every spare parts then checking and fixing.

Pressing die is the equipment for mould metal material, and also is the basic of plank anticipates for modeling. The pressing mould included many types, one of type which is used to bent and deformation is the bending mould. This bending mould is made by a kind of flections plank which thickness less than 1mm and having many bends. The working mechanism is by slider moved on inclined plane to realize the flections model by more then one action.

Key words: Crank Press; Electrical Machinery; Smooth Piece;Bending Mold;

Dyadic Wedge

道路就地冷再生机是在铣刨机基础上经过优化和改进的一种集合了翻挖、回收、破碎、筛分并与新料结合快速完成旧沥青路面的再生,使之能够满足一定的路用性能并用其重新铺筑路面的现代化新型机械。本设计为轮式就地冷再生机,具有铣刨和拌和功能,可双向作业,采用全液压四轮驱动,液压转向与制动。就地冷再生机为我国现存道路的维修养护和延长现存道路的服务年限提供了一种更经济、更合理和更高回报的道路建设和维修养护施工工艺及施工设备。

本文参考现有冷再生设备,对道路就地冷再生机的总体设计方案, 总体参数及装置零件的选择与计算,道路就地冷再生机的各种性能进行了分析,

关键词:就地冷再生机;总体设计;性能分析;参数计算;

ABSTRACT

Crank Press is a fundamental equipment, which makes a mould,and it is extensively applied in the production of industry. The crank press which was designed is mainly used for molding which be unable to bear a heavy pressure,then starting the engine of crank press to complete the bend forming process when after the crank press fixed. The working mechanism is supported by the linkage of crank which is changed the motor spinning activity into moving straight line (back and forth) through by crank, linkage and slider. The process of die spotting is causing by upper die which is shifted by slider. When the crank spines one time, the slider returns (back and forth) once, then finished one product. This design is mainly attend to measure and design the organization of mould; the choosing of pressure machine and electric motor; the design and measure of every spare parts then checking and fixing.

Pressing die is the equipment for mould metal material, and also is the basic of plank anticipates for modeling. The pressing mould included many types, one of type which is used to bent and deformation is the bending mould. This bending mould is made by a kind of flections plank which thickness less than 1mm and having many bends. The working mechanism is by slider moved on inclined plane to realize the flections model by more then one action.

Key words: Crank Press; Electrical Machinery; Smooth Piece;Bending Mold;

Dyadic Wedge

目 录

摘要………………………………………………………………………………………Ⅰ

Abstract…………………………………………………………………………………Ⅱ

第1章 概述……………………………………………………………………………1

1.1国内外道路就地冷再生机产品开发的概述………………………………1

1.2就地冷再生机的介绍…………………………………………………………1

1.2.1冷再生机械的分类…………………………………………………2

1.2.2冷再生主机的结构和工作原理………………………………………2

1.3 就地冷再生技术 …………………………………………………………………2

1.3.1道路就地冷再生的运用范围………………………………………………2

1.3.2道路就地冷再生的工艺优点………………………………………2

1.4 产品市场前景分析…………………………………………………………………2

第2章 道路就地冷再升级的总体方案设计……………………………………5

2.1 道路就地冷再生机总机设计…………………………………………5

2.1.1 动力系统………………………………………………………………6

2.1.2 工作装置传动系统…………………………………………………7

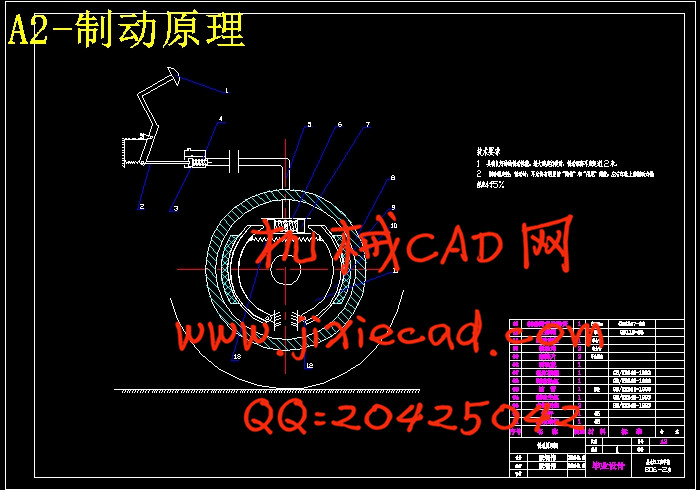

2.1.3 行走传动系统和制动系统………………………………………9

2.1.4转向传动系统……………………………………………………9

2.1.5 辅助液压缸传动系统……………………………………………6

2.1.6 电气系统…………………………………………………………7

2.1.7 喷洒系统………………………………………………………9

2.1.8铣削及其拌和转子……………………………………………9

2.2 道路就地冷再生机的施工工作参数指标……………………………………5

2.3 道路就地冷再生机的主要铣削参数的选择……………………………………6

第3章 总体参数以及装置零件的选择与计算…………………………………15

3.1 整机牵引力与牵引功率…………………………………………………………15

3.1.1 整机牵引力…………………………………………………………16

3.1.2牵引功率…………………………………………………………17

3.2 冷再生机的工作功率……………………………………………………18

3.2.1 铣削转子简介………………………………………………………6

3.2.2 铣削刀具受力分析…………………………………………………7

3.2.3切向铣削阻力的计算………………………………………………9

3.2.4铣削功率……………………………………………………………9

3.2.5 铣削转子注意事项…………………………………………………6

3.3 发动机的选择计算………………………………………………………………20

3.4装置零件的计算选择…………………………………………………………22

3.4.1 行走液压泵和马达的选择计算……………………………………6

3.4.2转向液压泵液马达、液压缸的选择及其校核计算………………………7

3.4.2.1 转向工作压力的确定………………………………………………6

3.4.2.2 转向器排量的选择…………………………………………………7

3.4.2.3转向流量的确定………………………………………………9

3.4.2.4转向泵排量的确定…………………………………………………9

3.4.2.5 优先阀的选择…………………………………………………6

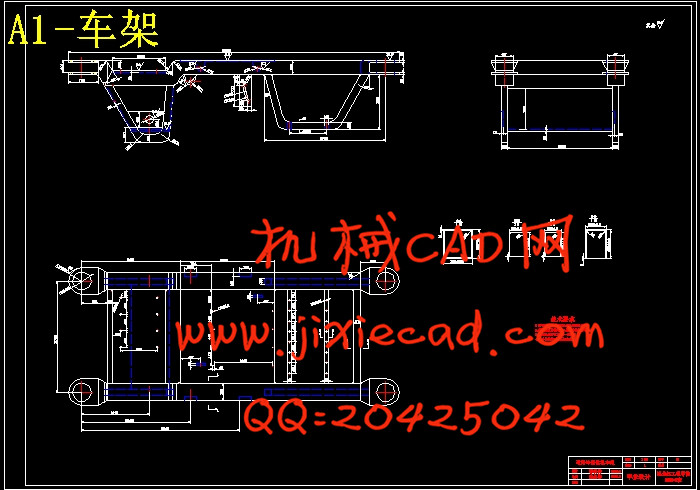

3.4.3 车架组合的选择校核计算…………………………………………6

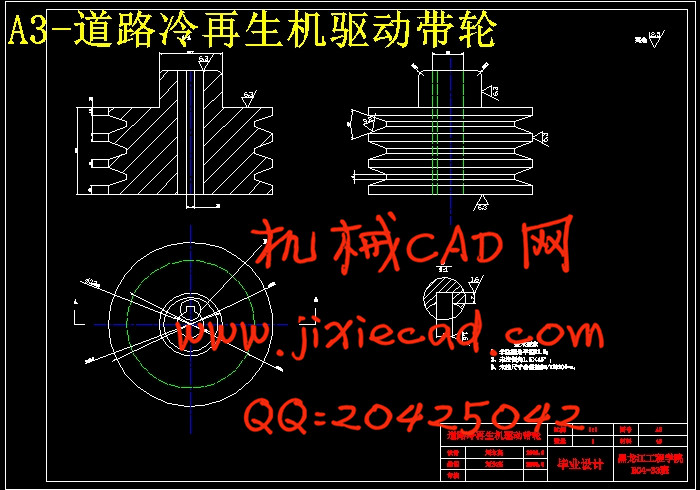

3.4.4转子驱动减速器、皮带及其皮带轮的计算…………………………7

第4章 道路就地冷再生机的性能分析…………………………………………24

4.1 转弯性能分析……………………………………………………………………24

4.2 爬坡性能分析……………………………………………………………27

4.3冷再生机的牵引功率平衡分析………………………………………………28

4.3.1 冷再生机功率分配……………………………………………………28

4.3.2 性能参数的合理匹配……………………………………………29

4.3.3 行走系统功率变化规律及影响因素……………………………………31

4.4 冷再生铣削性能分析……………………………………………33

第5章 产品功能分析……………………………………………………………38

5.1 产品功能…………………………………………………………………38

5.1.1 产品特点……………………………………………………28

5.1.2 产品主要技术参数……………………………………………29

结论………………………………………………………………………………………44

参考文献…………………………………………………………………………………45

致谢………………………………………………………………………………………46

摘要………………………………………………………………………………………Ⅰ

Abstract…………………………………………………………………………………Ⅱ

第1章 概述……………………………………………………………………………1

1.1国内外道路就地冷再生机产品开发的概述………………………………1

1.2就地冷再生机的介绍…………………………………………………………1

1.2.1冷再生机械的分类…………………………………………………2

1.2.2冷再生主机的结构和工作原理………………………………………2

1.3 就地冷再生技术 …………………………………………………………………2

1.3.1道路就地冷再生的运用范围………………………………………………2

1.3.2道路就地冷再生的工艺优点………………………………………2

1.4 产品市场前景分析…………………………………………………………………2

第2章 道路就地冷再升级的总体方案设计……………………………………5

2.1 道路就地冷再生机总机设计…………………………………………5

2.1.1 动力系统………………………………………………………………6

2.1.2 工作装置传动系统…………………………………………………7

2.1.3 行走传动系统和制动系统………………………………………9

2.1.4转向传动系统……………………………………………………9

2.1.5 辅助液压缸传动系统……………………………………………6

2.1.6 电气系统…………………………………………………………7

2.1.7 喷洒系统………………………………………………………9

2.1.8铣削及其拌和转子……………………………………………9

2.2 道路就地冷再生机的施工工作参数指标……………………………………5

2.3 道路就地冷再生机的主要铣削参数的选择……………………………………6

第3章 总体参数以及装置零件的选择与计算…………………………………15

3.1 整机牵引力与牵引功率…………………………………………………………15

3.1.1 整机牵引力…………………………………………………………16

3.1.2牵引功率…………………………………………………………17

3.2 冷再生机的工作功率……………………………………………………18

3.2.1 铣削转子简介………………………………………………………6

3.2.2 铣削刀具受力分析…………………………………………………7

3.2.3切向铣削阻力的计算………………………………………………9

3.2.4铣削功率……………………………………………………………9

3.2.5 铣削转子注意事项…………………………………………………6

3.3 发动机的选择计算………………………………………………………………20

3.4装置零件的计算选择…………………………………………………………22

3.4.1 行走液压泵和马达的选择计算……………………………………6

3.4.2转向液压泵液马达、液压缸的选择及其校核计算………………………7

3.4.2.1 转向工作压力的确定………………………………………………6

3.4.2.2 转向器排量的选择…………………………………………………7

3.4.2.3转向流量的确定………………………………………………9

3.4.2.4转向泵排量的确定…………………………………………………9

3.4.2.5 优先阀的选择…………………………………………………6

3.4.3 车架组合的选择校核计算…………………………………………6

3.4.4转子驱动减速器、皮带及其皮带轮的计算…………………………7

第4章 道路就地冷再生机的性能分析…………………………………………24

4.1 转弯性能分析……………………………………………………………………24

4.2 爬坡性能分析……………………………………………………………27

4.3冷再生机的牵引功率平衡分析………………………………………………28

4.3.1 冷再生机功率分配……………………………………………………28

4.3.2 性能参数的合理匹配……………………………………………29

4.3.3 行走系统功率变化规律及影响因素……………………………………31

4.4 冷再生铣削性能分析……………………………………………33

第5章 产品功能分析……………………………………………………………38

5.1 产品功能…………………………………………………………………38

5.1.1 产品特点……………………………………………………28

5.1.2 产品主要技术参数……………………………………………29

结论………………………………………………………………………………………44

参考文献…………………………………………………………………………………45

致谢………………………………………………………………………………………46