设计简介

低速载货汽车离合器的设计

摘要:离合器依靠其主、从动部分的摩擦来传递动力且能分离的机构。YC1040低速载货汽车中针对多数摩擦离合器存在散热能力不足,摩擦片易磨损等缺点的现状,根据生产的实际情况和需要,依据经济、可靠、操作方便的原则,采用单片干式摩擦离合器,为保证其技术先进性和经济合理性,还采取了以下措施:(1)为使离合器保证结构简单,尺寸紧凑,散热良好,维修调整方便,从动部分转动惯量小,在使用时能保证分离彻底、接合平顺,选择采用单片盘摩擦片。(2)为保证结构简单、制造容易,保证结构简单,制造方便,考虑压紧弹簧的结构形式选用周置弹簧,压紧弹簧采用圆柱螺旋弹簧。(3)压盘的驱动方式选用凸块-窗孔式,采用3个分离杠杆,且分离杠杆保证足够的刚度,使其工作可靠。(4)分离轴承选用开式的推力球轴承,改进润滑措施后,解决了这类轴承润滑条件差、磨损严重、噪声大、可靠性差、使用寿命低等缺点,在保证工作可靠的条件下降低制造成本。

通过本设计使其具有从动部分转动惯量小、散热性好、结构简单、调整方便、尺寸紧凑、分离彻底等优点,而且在结构上采取一定的措施,能使其结合平顺。

关键词:低速货汽车;离合器;设计

Design of the Clutch of the Low-speed Truck

Abstract: Depending upon the friction, clutch is a mechanism to transmit or disengage the power, In view of the shortcomings of present clutch’s insufficient thermal radiation ability is abrasion and according to the actual situation and needs of production and the principle of economical, reliable, easy to operate, The low speed truck YC1040 uses the monolithic dry type friction clutch, to ensure its technical progress and the economical rationality, it also has taken the following measurement : (1) In order to guarantee its simple structure, compact size, good radiates, convenient to adjustment , driven partial rotations inertia small, when use can guarantee the separation thorough, the joint is smooth, chose to uses the single bobbin friction disk.(2) In order to guarantee the structure simple, easy to manufacture, to guarantee structure simple, convenient to manufacture , considered contracts the spring the structural style to select the week to set at the spring, contracts the spring to use the column helical spring. (3) Presses the plate the drive type to select the ridge - window hole type, uses 3 separations release levers, also the separation release lever guarantee enough rigidity, make its work to be reliable.(4) The release bearing selects start -like the thrust force ball bearing, after the improvement of lubrication , seriously solved the bad condition of these bearing lubrication , attrition, big noise, badly reliability , low life etc shortcoming, reduced the cost of production under the conditions that it can guarantee the work to be reliable.

Tthis design can enable many merits which is that its driven partial rotations inertia small, the radiation be better, the structure is simply, convenient to adjustment, the size compact, the separation thorough and so on, moreover it also takes some measure in the structure, which can make its union to be smooth.

Key words:the Low-speed Truck; Clutch; Design

目 录

1前言 1

2总体方案论证 2

2.1离合器总成的结构和有关组件的结构 2

2.1.1从动盘数及干、湿式的选择 2

2.1.2压紧弹簧的结构型式及布置 2

2.1.3 压盘的驱动方式 4

2.1.4分离杠杆的结构型式 4

2.1.5分离轴承的类型 5

2.1.6离合器的通风散热措施 5

2.1.7从动盘的结构型式 6

2.1.8 离合器的操纵机构选择 6

2.2 结论 7

3汽车离合器的设计计算 9

3.1离合器主要参数的选择 9

3.2摩擦离合器主要零件的设计计算 12

3.2.1压紧弹簧的设计计算 12

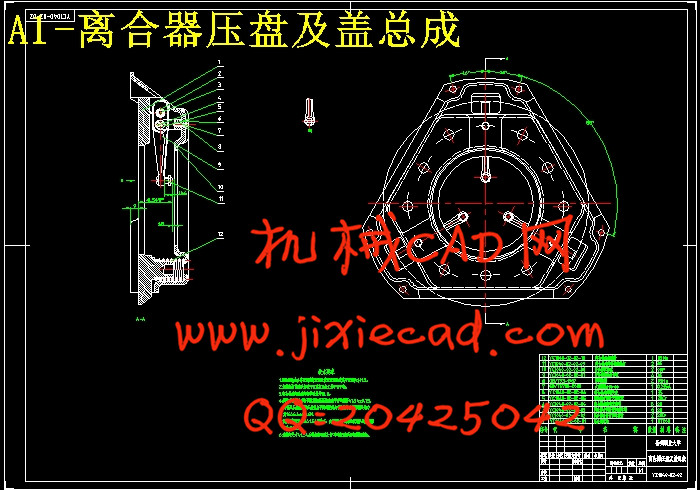

3.2.2压盘的设计计算 13

3.2.3从动片与从动盘毂的设计计算 14

3.2.4分离杠杆的设计计算 15

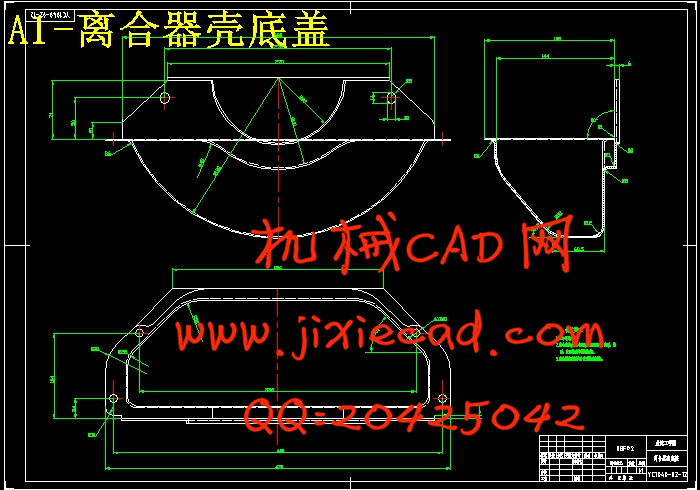

3.2.5离台器盖的设计计算 15

3.3离合器操纵机构设计 16

3.3.1离合器操纵机构的结构型式选择 16

3.3.2离合器分离行程及性能计算 18

4结论 19

参 考 文 献 20

致 谢 21

摘要:离合器依靠其主、从动部分的摩擦来传递动力且能分离的机构。YC1040低速载货汽车中针对多数摩擦离合器存在散热能力不足,摩擦片易磨损等缺点的现状,根据生产的实际情况和需要,依据经济、可靠、操作方便的原则,采用单片干式摩擦离合器,为保证其技术先进性和经济合理性,还采取了以下措施:(1)为使离合器保证结构简单,尺寸紧凑,散热良好,维修调整方便,从动部分转动惯量小,在使用时能保证分离彻底、接合平顺,选择采用单片盘摩擦片。(2)为保证结构简单、制造容易,保证结构简单,制造方便,考虑压紧弹簧的结构形式选用周置弹簧,压紧弹簧采用圆柱螺旋弹簧。(3)压盘的驱动方式选用凸块-窗孔式,采用3个分离杠杆,且分离杠杆保证足够的刚度,使其工作可靠。(4)分离轴承选用开式的推力球轴承,改进润滑措施后,解决了这类轴承润滑条件差、磨损严重、噪声大、可靠性差、使用寿命低等缺点,在保证工作可靠的条件下降低制造成本。

通过本设计使其具有从动部分转动惯量小、散热性好、结构简单、调整方便、尺寸紧凑、分离彻底等优点,而且在结构上采取一定的措施,能使其结合平顺。

关键词:低速货汽车;离合器;设计

Design of the Clutch of the Low-speed Truck

Abstract: Depending upon the friction, clutch is a mechanism to transmit or disengage the power, In view of the shortcomings of present clutch’s insufficient thermal radiation ability is abrasion and according to the actual situation and needs of production and the principle of economical, reliable, easy to operate, The low speed truck YC1040 uses the monolithic dry type friction clutch, to ensure its technical progress and the economical rationality, it also has taken the following measurement : (1) In order to guarantee its simple structure, compact size, good radiates, convenient to adjustment , driven partial rotations inertia small, when use can guarantee the separation thorough, the joint is smooth, chose to uses the single bobbin friction disk.(2) In order to guarantee the structure simple, easy to manufacture, to guarantee structure simple, convenient to manufacture , considered contracts the spring the structural style to select the week to set at the spring, contracts the spring to use the column helical spring. (3) Presses the plate the drive type to select the ridge - window hole type, uses 3 separations release levers, also the separation release lever guarantee enough rigidity, make its work to be reliable.(4) The release bearing selects start -like the thrust force ball bearing, after the improvement of lubrication , seriously solved the bad condition of these bearing lubrication , attrition, big noise, badly reliability , low life etc shortcoming, reduced the cost of production under the conditions that it can guarantee the work to be reliable.

Tthis design can enable many merits which is that its driven partial rotations inertia small, the radiation be better, the structure is simply, convenient to adjustment, the size compact, the separation thorough and so on, moreover it also takes some measure in the structure, which can make its union to be smooth.

Key words:the Low-speed Truck; Clutch; Design

目 录

1前言 1

2总体方案论证 2

2.1离合器总成的结构和有关组件的结构 2

2.1.1从动盘数及干、湿式的选择 2

2.1.2压紧弹簧的结构型式及布置 2

2.1.3 压盘的驱动方式 4

2.1.4分离杠杆的结构型式 4

2.1.5分离轴承的类型 5

2.1.6离合器的通风散热措施 5

2.1.7从动盘的结构型式 6

2.1.8 离合器的操纵机构选择 6

2.2 结论 7

3汽车离合器的设计计算 9

3.1离合器主要参数的选择 9

3.2摩擦离合器主要零件的设计计算 12

3.2.1压紧弹簧的设计计算 12

3.2.2压盘的设计计算 13

3.2.3从动片与从动盘毂的设计计算 14

3.2.4分离杠杆的设计计算 15

3.2.5离台器盖的设计计算 15

3.3离合器操纵机构设计 16

3.3.1离合器操纵机构的结构型式选择 16

3.3.2离合器分离行程及性能计算 18

4结论 19

参 考 文 献 20

致 谢 21