设计简介

低速载货汽车的后驱动桥设计

摘要:驱动桥采用普通非断开式驱动桥。它结构简单、造价低廉、工作可靠,广泛应用于各种载货汽车。其特点是桥壳是一根支撑在左、右驱动车轮上的刚性空心梁,而齿轮及半轴等所有的传动机件都装在其中。采用组合式桥壳的单级主减速器。单级主减速器代替双级主减速器可大大减小驱动桥的质量。其具有结构简单、质量小、尺寸紧凑及制造成本低等优点。差速器则采用对称式圆锥行星齿轮差速器。差速器壳装在主减速器从动齿轮上。结构简单、工作平稳、制造方便是选择它的主要原因。另外,采用可分式桥壳。整个桥壳由一个垂直结合面分为左右两个部分,每一个部分均由一个铸件壳体和一个压入其外端的半轴套管组成。该结构的桥壳制造工艺简单、主减速器轴承支承刚度好。

本设计从所设计的汽车的类型及使用、生产条件出发,并和所设计汽车的其他部件相适应,设计出既定用途的汽车的驱动桥,从而保证所设计汽车的最重要的使用性能的实现。

关键字:低速货车;驱动桥;设计。

Design of the transaxle of the low-speed truck

Abstract: The transaxle adopts the ordinary not-disconnecting-type transaxle. Because of its simple structure, cheap fabrication cost and reliability, it is applied widely. Its Characteristic is that the bridge shell is a rigidity hollow beam which is supported on the left and right wheels, gears, half-axis and other transmission components. The main gear box uses combined type single stage. The single stage compared to double one can reduce the quality of the transaxle a lot. It has many merits of simple structure, small quality, compact size, low production cost. The differential mass uses symmetrical type and circular cone planet gear. The shell of the differential device is assembled with the driven gear of the transaxle that it is has advantages of simple structure, steadily work and conveniently making. It uses separated type axis shell. The whole shell is divided in to left and right parts by vertical plane. Every part is made up of a casting shell and a semi-axis driven tube which is pressed in outside. This structure has advantages of simple manufacture craft and good supporting rigidity of main gear box bearing.

This design is proceeded from the types, production and working of the truck. It is adapted to other parts of the truck design. At last, the set use transaxle of the truck is designed, to ensure the most important operational performance of the truck is realized.

Key words: Low speed truck, Transaxle, Design.

目录

1 前言 1

1.1 本课题的来源、基本前提条件和技术要求 1

1.2 本课题要解决的主要问题和设计总体思路 1

1.3 预期的成果 2

2 国内外发展状况及现状的介绍 3

3 总体方案论证 4

4 具体设计说明 7

4.1 主减速器的设计 7

4.1.1 主减速器的结构型式 7

4.1.2 主减速器主动锥齿轮的支承型式及安装方法 10

4.1.3 主减速器从动锥齿轮的支承型式及安装方法 11

4.1.4 主减速器的基本参数的选择及计算 11

4.2 差速器的设计 14

4.2.1差速器的结构型式 14

4.2.2差速器的基本参数的选择及计算 16

4.3 半轴的设计 17

4.3.1半轴的结构型式 17

4.3.2半轴的设计与计算 17

4.4驱动桥壳结构选择 20

5 结论 22

参 考 文 献 23

摘要:驱动桥采用普通非断开式驱动桥。它结构简单、造价低廉、工作可靠,广泛应用于各种载货汽车。其特点是桥壳是一根支撑在左、右驱动车轮上的刚性空心梁,而齿轮及半轴等所有的传动机件都装在其中。采用组合式桥壳的单级主减速器。单级主减速器代替双级主减速器可大大减小驱动桥的质量。其具有结构简单、质量小、尺寸紧凑及制造成本低等优点。差速器则采用对称式圆锥行星齿轮差速器。差速器壳装在主减速器从动齿轮上。结构简单、工作平稳、制造方便是选择它的主要原因。另外,采用可分式桥壳。整个桥壳由一个垂直结合面分为左右两个部分,每一个部分均由一个铸件壳体和一个压入其外端的半轴套管组成。该结构的桥壳制造工艺简单、主减速器轴承支承刚度好。

本设计从所设计的汽车的类型及使用、生产条件出发,并和所设计汽车的其他部件相适应,设计出既定用途的汽车的驱动桥,从而保证所设计汽车的最重要的使用性能的实现。

关键字:低速货车;驱动桥;设计。

Design of the transaxle of the low-speed truck

Abstract: The transaxle adopts the ordinary not-disconnecting-type transaxle. Because of its simple structure, cheap fabrication cost and reliability, it is applied widely. Its Characteristic is that the bridge shell is a rigidity hollow beam which is supported on the left and right wheels, gears, half-axis and other transmission components. The main gear box uses combined type single stage. The single stage compared to double one can reduce the quality of the transaxle a lot. It has many merits of simple structure, small quality, compact size, low production cost. The differential mass uses symmetrical type and circular cone planet gear. The shell of the differential device is assembled with the driven gear of the transaxle that it is has advantages of simple structure, steadily work and conveniently making. It uses separated type axis shell. The whole shell is divided in to left and right parts by vertical plane. Every part is made up of a casting shell and a semi-axis driven tube which is pressed in outside. This structure has advantages of simple manufacture craft and good supporting rigidity of main gear box bearing.

This design is proceeded from the types, production and working of the truck. It is adapted to other parts of the truck design. At last, the set use transaxle of the truck is designed, to ensure the most important operational performance of the truck is realized.

Key words: Low speed truck, Transaxle, Design.

目录

1 前言 1

1.1 本课题的来源、基本前提条件和技术要求 1

1.2 本课题要解决的主要问题和设计总体思路 1

1.3 预期的成果 2

2 国内外发展状况及现状的介绍 3

3 总体方案论证 4

4 具体设计说明 7

4.1 主减速器的设计 7

4.1.1 主减速器的结构型式 7

4.1.2 主减速器主动锥齿轮的支承型式及安装方法 10

4.1.3 主减速器从动锥齿轮的支承型式及安装方法 11

4.1.4 主减速器的基本参数的选择及计算 11

4.2 差速器的设计 14

4.2.1差速器的结构型式 14

4.2.2差速器的基本参数的选择及计算 16

4.3 半轴的设计 17

4.3.1半轴的结构型式 17

4.3.2半轴的设计与计算 17

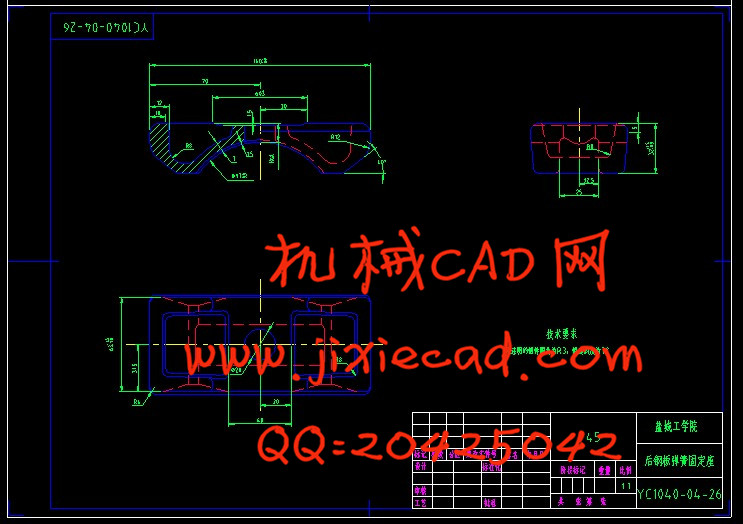

4.4驱动桥壳结构选择 20

5 结论 22

参 考 文 献 23