设计简介

摘 要

泵是输送液体或使液体增压的机械装置,它可以将原动机的机械能或其它外部能量传送给液体,使液体的能量增加。它的出现给工农业生产带来了极大的便利,是现代化生产中不可缺少的组成部分。泵的种类很多,但由于往复泵所具有的一些性能上的特点和优点是其它类型泵所无法比拟的,因而它的应用也不可被取代。

本文论述了低温活塞泵的国内外发展状况,并针对活塞泵进行了结构设计和理论分析。课题的主要内容是设计并研制出一个低温活塞泵系统,主要是在活塞泵的设计方面,并且对于材料等有一定的要求。首先是整体设计,主要包括设计参数和结构参数的选择及电动机的选择;其次是液力端的设计,主要是活塞、吸入排出阀和缸体的结构设计;最后是传动端的设计,包括曲轴、连杆、十字头、皮带等部件的设计。

关键词:低温活塞泵;结构参数;活塞;曲轴;连杆

ABSTRACT

Pump is such a machinery which can transport liquid or make liquid pressurize, and it also can make driver's energy or other exterior energy transmit to liquid in order to increase its energy. Its appearance brings infinite convenience for the industrial and agriculture, and it is indispensable component in the modern production. There are many kinds of pump, due to the characteristics and virtue of piston pump, which other pumps can't be matched; its appliance may not be replaced.

This paper introduces the development condition to the piston pump home and abroad, and makes design and theoretical analysis. The thesis is to design and develop a low-temperature piston pump system, the design of piston pump is primary, and there are certain requirements to material. Firstly, it is the overall design comprising the choice of design parameter and structure parameter, as well as the choice of the motor. Secondly, the design of liquid force port mainly is the structure design of piston, inhalation and discharge valve, together with cylinder. Finally, it is the design of transmission, containing the design of crankshaft, linkage, crosshead, belt and other parts.

Key words: The Low-temperature Piston Pump; Structure Parameter; Piston; Crankshaft; Linkage

目 录

摘要……………………………………………………………………………………Ⅰ

Abstract………………………………………………………………………………Ⅱ

第1章 绪论…………………………………………………………………………1

1.1 本课题研究目的和意义………………………………………………………1

1.2国内外发展概况和发展前景…………………………………………………1

1.3泵的概述………………………………………………………………………2

1.3.1 泵的发展史………………………………………………………… 2

1.3.2 泵的分类…………………………………………………………… 3

1.3.3 低温活塞泵………………………………………………………… 4

第2章 低温活塞泵的整体设计…………………………………………………8

2.1方案设计………………………………………………………………………8

2.2参数选择………………………………………………………………………8

2.2.1设计参数………………………………………………………………8

2.2.2结构参数………………………………………………………………9

2.3驱动形式的选择………………………………………………………………10

2.3.1驱动的分类…………………………………………………………10

2.3.2驱动电机的选择……………………………………………………12

2.4本章小结………………………………………………………………………13

第3章 低温活塞泵的液力端……………………………………………………14

3.1液力端的结构及工作原理……………………………………………………14

3.1.1液力端结构的设计原理………………………………………………14

3.1.2结构及原理……………………………………………………………14

3.2液力端的设计………………………………………………………………14

3.2.1液力端材料的选取……………………………………………………14

3.2.2液缸体…………………………………………………………………15

3.3密封及其它……………………………………………………………………16

3.3.1密封…………………………………………………………………16

3.3.2摩擦及润滑…………………………………………………………17

3.3.3气体回收及绝热……………………………………………………18

3.3.4绝热…………………………………………………………………18

3.4本章小结………………………………………………………………………19

第4章 低温活塞泵的传动端…………………………………………………… 20

4.1传动端的工作原理……………………………………………………………20

4.2传动端的结构设计……………………………………………………………20

4.3曲轴的设计……………………………………………………………………21

4.3.1曲轴主要尺寸的初步确定……………………………………………22

4.3.2曲轴强度校核…………………………………………………………22

4.4连杆的设计……………………………………………………………………23

4.4.1连杆体截面最小强度校核……………………………………………23

4.4.2销连接小头强度校核…………………………………………………24

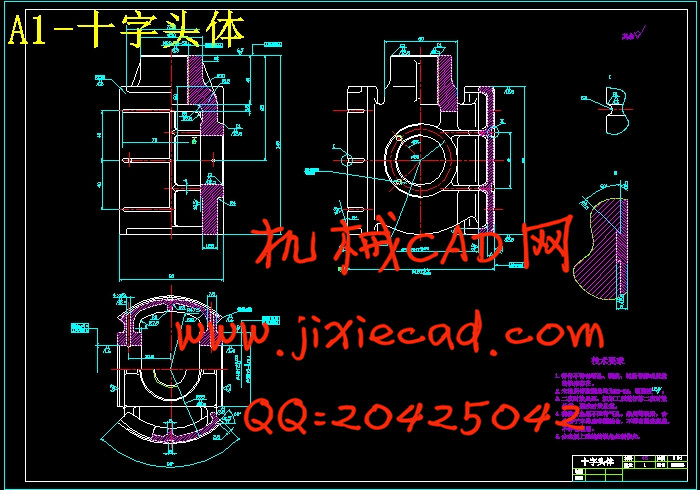

4.5十字头的设计…………………………………………………………………25

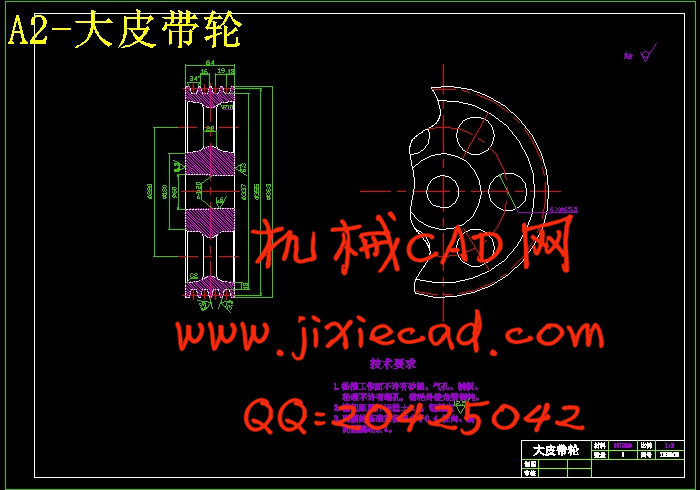

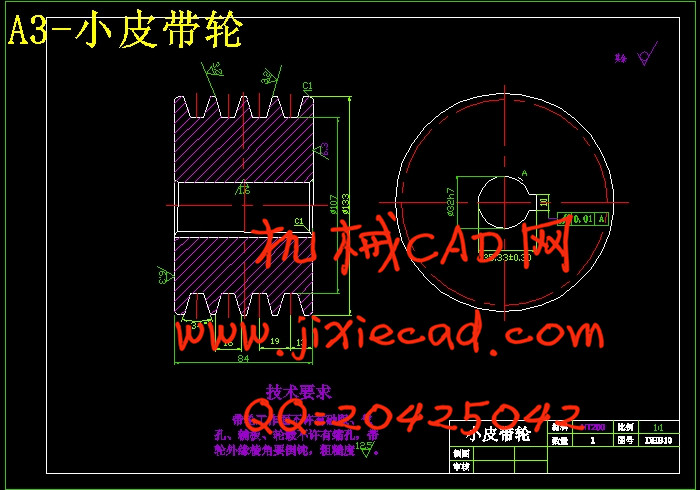

4.6皮带及其它……………………………………………………………………26

4.6.1皮带传动设计…………………………………………………………26

4.6.2其它……………………………………………………………………28

4.7本章小结………………………………………………………………………28

结论……………………………………………………………………………………29

参考文献………………………………………………………………………………30

致谢……………………………………………………………………………………31

泵是输送液体或使液体增压的机械装置,它可以将原动机的机械能或其它外部能量传送给液体,使液体的能量增加。它的出现给工农业生产带来了极大的便利,是现代化生产中不可缺少的组成部分。泵的种类很多,但由于往复泵所具有的一些性能上的特点和优点是其它类型泵所无法比拟的,因而它的应用也不可被取代。

本文论述了低温活塞泵的国内外发展状况,并针对活塞泵进行了结构设计和理论分析。课题的主要内容是设计并研制出一个低温活塞泵系统,主要是在活塞泵的设计方面,并且对于材料等有一定的要求。首先是整体设计,主要包括设计参数和结构参数的选择及电动机的选择;其次是液力端的设计,主要是活塞、吸入排出阀和缸体的结构设计;最后是传动端的设计,包括曲轴、连杆、十字头、皮带等部件的设计。

关键词:低温活塞泵;结构参数;活塞;曲轴;连杆

ABSTRACT

Pump is such a machinery which can transport liquid or make liquid pressurize, and it also can make driver's energy or other exterior energy transmit to liquid in order to increase its energy. Its appearance brings infinite convenience for the industrial and agriculture, and it is indispensable component in the modern production. There are many kinds of pump, due to the characteristics and virtue of piston pump, which other pumps can't be matched; its appliance may not be replaced.

This paper introduces the development condition to the piston pump home and abroad, and makes design and theoretical analysis. The thesis is to design and develop a low-temperature piston pump system, the design of piston pump is primary, and there are certain requirements to material. Firstly, it is the overall design comprising the choice of design parameter and structure parameter, as well as the choice of the motor. Secondly, the design of liquid force port mainly is the structure design of piston, inhalation and discharge valve, together with cylinder. Finally, it is the design of transmission, containing the design of crankshaft, linkage, crosshead, belt and other parts.

Key words: The Low-temperature Piston Pump; Structure Parameter; Piston; Crankshaft; Linkage

目 录

摘要……………………………………………………………………………………Ⅰ

Abstract………………………………………………………………………………Ⅱ

第1章 绪论…………………………………………………………………………1

1.1 本课题研究目的和意义………………………………………………………1

1.2国内外发展概况和发展前景…………………………………………………1

1.3泵的概述………………………………………………………………………2

1.3.1 泵的发展史………………………………………………………… 2

1.3.2 泵的分类…………………………………………………………… 3

1.3.3 低温活塞泵………………………………………………………… 4

第2章 低温活塞泵的整体设计…………………………………………………8

2.1方案设计………………………………………………………………………8

2.2参数选择………………………………………………………………………8

2.2.1设计参数………………………………………………………………8

2.2.2结构参数………………………………………………………………9

2.3驱动形式的选择………………………………………………………………10

2.3.1驱动的分类…………………………………………………………10

2.3.2驱动电机的选择……………………………………………………12

2.4本章小结………………………………………………………………………13

第3章 低温活塞泵的液力端……………………………………………………14

3.1液力端的结构及工作原理……………………………………………………14

3.1.1液力端结构的设计原理………………………………………………14

3.1.2结构及原理……………………………………………………………14

3.2液力端的设计………………………………………………………………14

3.2.1液力端材料的选取……………………………………………………14

3.2.2液缸体…………………………………………………………………15

3.3密封及其它……………………………………………………………………16

3.3.1密封…………………………………………………………………16

3.3.2摩擦及润滑…………………………………………………………17

3.3.3气体回收及绝热……………………………………………………18

3.3.4绝热…………………………………………………………………18

3.4本章小结………………………………………………………………………19

第4章 低温活塞泵的传动端…………………………………………………… 20

4.1传动端的工作原理……………………………………………………………20

4.2传动端的结构设计……………………………………………………………20

4.3曲轴的设计……………………………………………………………………21

4.3.1曲轴主要尺寸的初步确定……………………………………………22

4.3.2曲轴强度校核…………………………………………………………22

4.4连杆的设计……………………………………………………………………23

4.4.1连杆体截面最小强度校核……………………………………………23

4.4.2销连接小头强度校核…………………………………………………24

4.5十字头的设计…………………………………………………………………25

4.6皮带及其它……………………………………………………………………26

4.6.1皮带传动设计…………………………………………………………26

4.6.2其它……………………………………………………………………28

4.7本章小结………………………………………………………………………28

结论……………………………………………………………………………………29

参考文献………………………………………………………………………………30

致谢……………………………………………………………………………………31