设计简介

内容提要

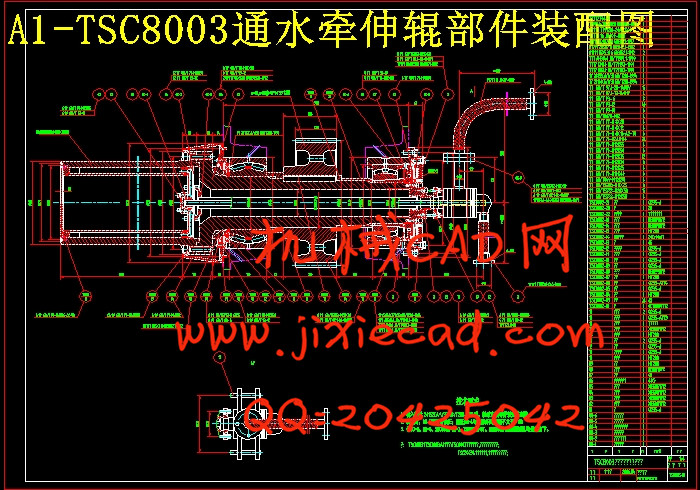

涤纶短纤维后处理设备七辊牵伸机牵伸辊属于牵伸机的工作部分,合理设计将提高七辊牵伸机的性能。牵伸机是纺丝后处理的主要设备之一,根据纺丝的工艺要求来确定牵伸机的数量和功率。本次设计的七辊牵伸机主要是为了提高年产量,从牵伸机组的整体设计出发,按照总牵伸倍数合理布局各级牵伸倍数,按照年产量计算最大牵伸旦数,最大牵伸力;按照牵伸力求出第三牵伸机辊筒的受力情况,依据最大辊筒受力来对辊筒进行强度、刚度校核,及其螺钉的校核。

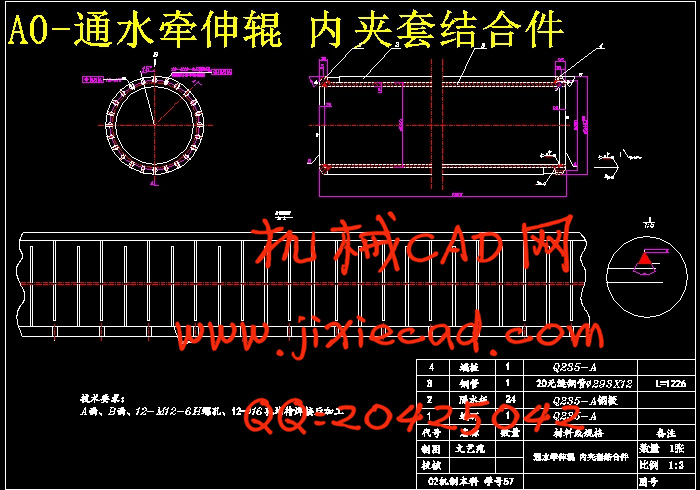

根据受力情况对牵伸辊和牵伸轴进行结构设计,要求结构简单、加工方便、经济可行。牵伸辊的联接的方式采用法兰联接,比内夹套联接结构简单、装配方便。合理设计通水牵伸辊部件,利用分配板使进水和出水流量均匀,充分带走热量。参照现有的七辊牵伸机设备,设计出满足工作要求的牵伸辊,以达到大容量生产涤纶短纤维的目的,满足现代高速纺织机械的发展。

On the basis of the roller’s force designing the frames of the drawing rollers and drawing shafts, which require simple frames, convenient manufacturing, economical and feasible. The link method of the drawing roller adopts flanges, which compares with the inner sleeve link has simple structure, convenient assemblage. Correctly designing the watering drawing roller parts, using the distributing board making the in water and out water equably flowing, and taking out the heat. Consulting the existent 7-roller drawing machine equipments, designing drawing rollers which satisfy the work requirement, and reach the objective of a large amount of polyester staple are produced, meet contemporary high-speed textile mechanical development.

目录

前言 1

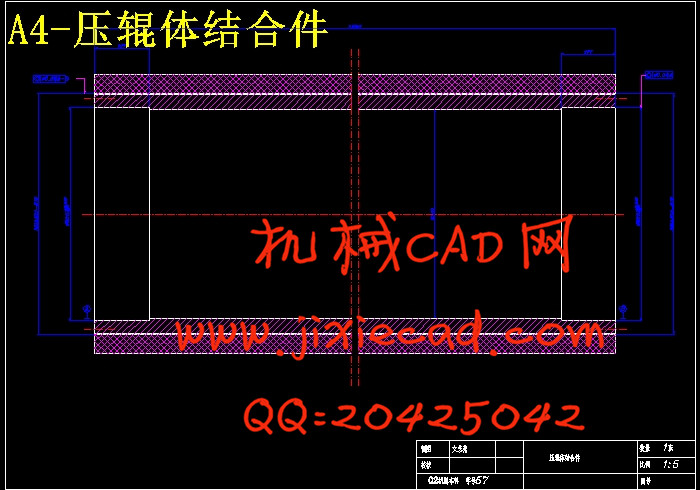

1 概述 2

1.1 拉伸的目的和作用 2

1.2 牵伸机组原理 2

2 设计参数的确定 4

2.1 年产2万吨涤纶短纤后处理工艺流程 4

2.2 设计基础 4

2.3确定牵伸旦数D 5

3 牵伸机构受力分析 5

4 第三牵伸机功率估算 6

5 七辊牵伸机的整体分析 8

5.1 第一牵伸机设计 8

5.2 第二牵伸机设计 9

5.3 第三牵伸机设计 10

6 牵伸辊受力分析 11

7 牵伸辊筒的设计 16

8 法兰联接螺钉性能等级和材料确定 18

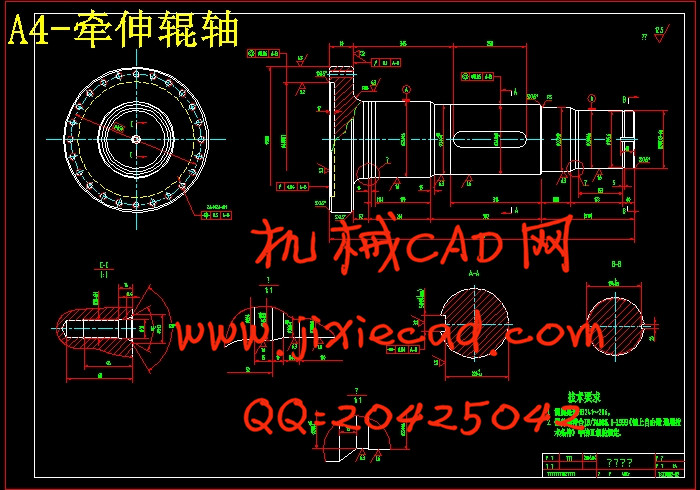

9 通水牵伸轴设计 20

10 牵伸辊的校核计算 25

10.1 强度计算 25

10.2 挠度计算 26

11 润滑方式与密封装置 28

总结 30

参考文献 31

致谢 32

涤纶短纤维后处理设备七辊牵伸机牵伸辊属于牵伸机的工作部分,合理设计将提高七辊牵伸机的性能。牵伸机是纺丝后处理的主要设备之一,根据纺丝的工艺要求来确定牵伸机的数量和功率。本次设计的七辊牵伸机主要是为了提高年产量,从牵伸机组的整体设计出发,按照总牵伸倍数合理布局各级牵伸倍数,按照年产量计算最大牵伸旦数,最大牵伸力;按照牵伸力求出第三牵伸机辊筒的受力情况,依据最大辊筒受力来对辊筒进行强度、刚度校核,及其螺钉的校核。

根据受力情况对牵伸辊和牵伸轴进行结构设计,要求结构简单、加工方便、经济可行。牵伸辊的联接的方式采用法兰联接,比内夹套联接结构简单、装配方便。合理设计通水牵伸辊部件,利用分配板使进水和出水流量均匀,充分带走热量。参照现有的七辊牵伸机设备,设计出满足工作要求的牵伸辊,以达到大容量生产涤纶短纤维的目的,满足现代高速纺织机械的发展。

Abstract

Polyester staple aftertreatment equipment 7-roller drawing machine’s rollers are work part of the drawing machine. And the performance of 7-roller drawing machine will be improved if it’s correctly designed. The drawing machine is one of the main equipments in the filature aftertreatment. According to the filature processing requirement we can decide the number and power of the drawing machine. This 7-roller drawing machine design is to enhance the annual output. Taking the drawing machine group as an organic whole design, through the total drawing multiple properly distributing each class drawing multiple, according to the annual output calculating the maximal drawing denier and maximal drawing tension, then on the basis of the drawing tension figuring out the force of third drawing machine roller, and according to the maximal roller force checking the intensity and rigidity and proofing the bolt.On the basis of the roller’s force designing the frames of the drawing rollers and drawing shafts, which require simple frames, convenient manufacturing, economical and feasible. The link method of the drawing roller adopts flanges, which compares with the inner sleeve link has simple structure, convenient assemblage. Correctly designing the watering drawing roller parts, using the distributing board making the in water and out water equably flowing, and taking out the heat. Consulting the existent 7-roller drawing machine equipments, designing drawing rollers which satisfy the work requirement, and reach the objective of a large amount of polyester staple are produced, meet contemporary high-speed textile mechanical development.

目录

前言 1

1 概述 2

1.1 拉伸的目的和作用 2

1.2 牵伸机组原理 2

2 设计参数的确定 4

2.1 年产2万吨涤纶短纤后处理工艺流程 4

2.2 设计基础 4

2.3确定牵伸旦数D 5

3 牵伸机构受力分析 5

4 第三牵伸机功率估算 6

5 七辊牵伸机的整体分析 8

5.1 第一牵伸机设计 8

5.2 第二牵伸机设计 9

5.3 第三牵伸机设计 10

6 牵伸辊受力分析 11

7 牵伸辊筒的设计 16

8 法兰联接螺钉性能等级和材料确定 18

9 通水牵伸轴设计 20

10 牵伸辊的校核计算 25

10.1 强度计算 25

10.2 挠度计算 26

11 润滑方式与密封装置 28

总结 30

参考文献 31

致谢 32