设计简介

点焊工作台的设计

摘要:随着计算机的飞速发展,计算机外围设备特别是硬盘驱动器正趋向小型化、高密度化和高速度化。硬盘驱动器是由承担记录介质的磁盘、进行读写的磁头、信号处理线路系统、磁头和磁盘的机械驱动系统等组成。经过十多年的研究,和随着新型材料的不断产生, 硬盘驱动器的尺寸已从开始的14英寸逐渐减小至3.5英寸,2.5英寸甚至1.8英寸。而作为硬盘驱动器的核心部件,磁头的尺寸更小、精度更高、性能更好。随着磁头性能的提高,对其加工焊接等方法提出了刚搞的要求。在高质量的磁头与PCB板的焊接中我们采用激光焊接。激光焊接时,所需的能量密度较低,只要将工件的加工区烧熔,并将其粘合在一起即可。因此,可以减少激光的输出功率。按照接头形式的不同,激光焊接也可以分为对接、端接、直接连接、深穿入熔化焊等。激光焊接既可采用脉冲焊,也可采用连续焊。激光焊接有如下优点:光照时间短,焊接过程迅速,不仅有利于提高生产率,而且热影响区销,不易氧化,适于焊接热敏感的材料;激光焊接没有焊渣,也不需要除氧化膜,可以透过玻璃在真空中进行,适用于微型机器仪表的焊接;激光焊接的工作范围广,可以实现各种材料的连接,如陶瓷业金属的连接。同时焊接专用夹具的设计可以提高磁头焊接的效率与精度,具有较高的经济适用效益。

关键词:激光;点焊;磁头;夹具

The design of laser spot welding bench

Abstract: With the rapid development of computers, computer peripheral equipment especially hard drive are incline to miniaturization, high density and high speed. Hard disk drive is borne by the recording medium disk, to read and write head, signal processing system, a magnetic head and disk mechanical driving system. After more than 10 years of research, and with the new material unceasingly produces, hard drive size has been from the beginning of the14 inch decreases gradually to 3.5 inches,2.5 inches and1.8 inches. As a hard disk drive magnetic head core components, smaller size, higher precision, better performance. As the head performance is improved, the processing and welding method is put forward just got requirements. In the quality of the head and the PCB board welding is used in laser welding. Laser welding, the energy density required is low, as long as the processing area of the workpiece burn, and the adhesive can be together. Therefore, can reduce the laser output power. According to the different forms of joint, the laser welding can also be divided into docking, termination, direct connection, deep penetration fusion welding. Laser welding can be used with either the pulse welding, can also be used for continuous welding. Laser welding has the advantages as follows: illumination time is short, the welding process is rapid, not only improve productivity, but also the heat affected zone of pin, is not easy to be oxidized, suitable for welding of heat sensitive materials; laser welding without welding slag, also do not need to remove the oxide film, can be through the glass in a vacuum, applicable to miniature machine instrumentation welding; laser welding working range, can achieve a variety of material connection, such as ceramics metal connection. At the same time ,welding fixture design can improve the efficiency and precision of magnetic head welding, so it has high economical benefit.

Key words: laser; spot welding; magnetic head; fixture

目 录

引言 ...........................................................................................................................1

1 绪论 ...........................................................................................................................2

1.1 设计研究的目的和意义..................................................................................2

1.2 激光点焊机的应用与发展...............................................................................2

1.3 设计拟解决的关键问题...................................................................................4

2 焊接工件磁头的简介............................................................................................5

2.1 硬盘驱动器结构 .......... .................................................................................5

2.2 硬盘驱动器工作原理.....................................................................................6

2.4 磁头种类简介 ................................................................................................8

2.5 磁头材料 ........................................................................................................9

3 焊接方式激光点焊 ............................................................................................12

3.1 激光锡球焊接过程优化 ...............................................................................12

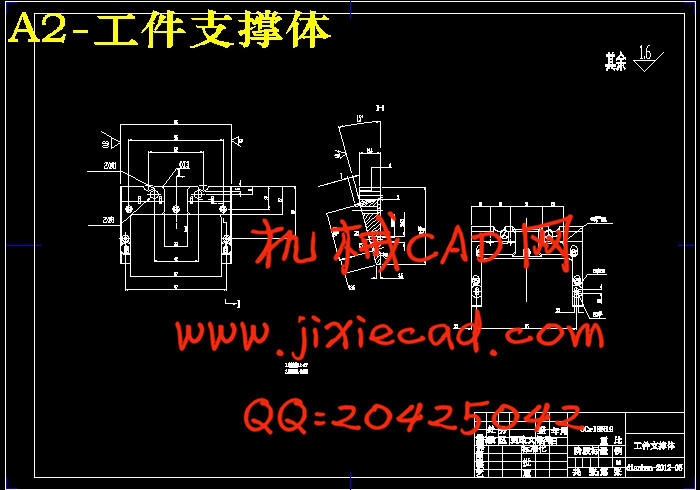

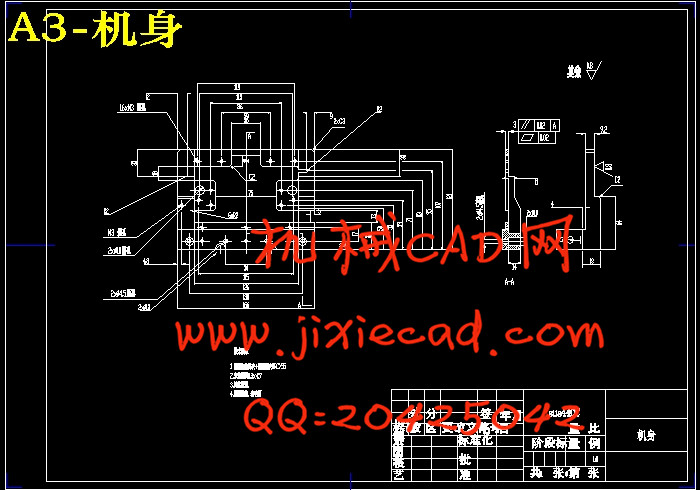

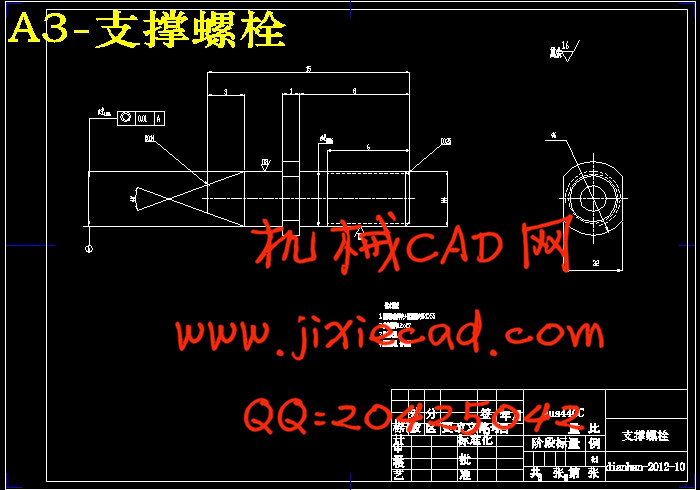

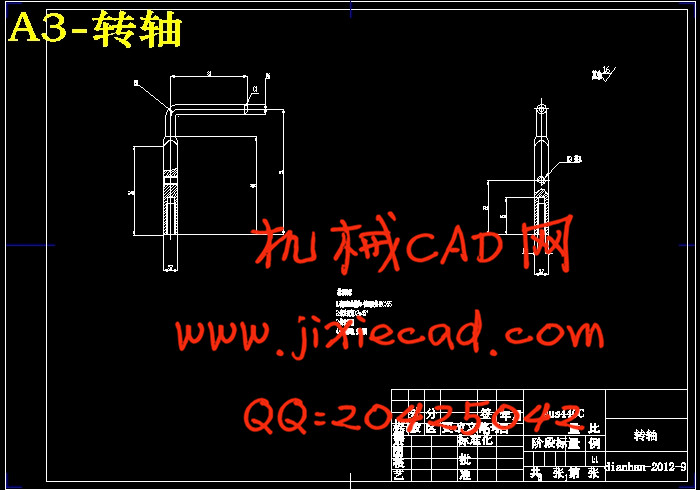

4 焊接夹具的设计 . ................................................................................................24

4.1 夹具的一般特性 ...........................................................................................24

4.2 夹具设计方案的确定 ................................................................................26

4.3 拉伸弹簧设计步骤 .........................................................................................37

4.1 定位误差分析 .........................................................................................41

参考文献 ......................................................................................................................44

谢辞 ................................................................................................................................45

摘要:随着计算机的飞速发展,计算机外围设备特别是硬盘驱动器正趋向小型化、高密度化和高速度化。硬盘驱动器是由承担记录介质的磁盘、进行读写的磁头、信号处理线路系统、磁头和磁盘的机械驱动系统等组成。经过十多年的研究,和随着新型材料的不断产生, 硬盘驱动器的尺寸已从开始的14英寸逐渐减小至3.5英寸,2.5英寸甚至1.8英寸。而作为硬盘驱动器的核心部件,磁头的尺寸更小、精度更高、性能更好。随着磁头性能的提高,对其加工焊接等方法提出了刚搞的要求。在高质量的磁头与PCB板的焊接中我们采用激光焊接。激光焊接时,所需的能量密度较低,只要将工件的加工区烧熔,并将其粘合在一起即可。因此,可以减少激光的输出功率。按照接头形式的不同,激光焊接也可以分为对接、端接、直接连接、深穿入熔化焊等。激光焊接既可采用脉冲焊,也可采用连续焊。激光焊接有如下优点:光照时间短,焊接过程迅速,不仅有利于提高生产率,而且热影响区销,不易氧化,适于焊接热敏感的材料;激光焊接没有焊渣,也不需要除氧化膜,可以透过玻璃在真空中进行,适用于微型机器仪表的焊接;激光焊接的工作范围广,可以实现各种材料的连接,如陶瓷业金属的连接。同时焊接专用夹具的设计可以提高磁头焊接的效率与精度,具有较高的经济适用效益。

关键词:激光;点焊;磁头;夹具

The design of laser spot welding bench

Abstract: With the rapid development of computers, computer peripheral equipment especially hard drive are incline to miniaturization, high density and high speed. Hard disk drive is borne by the recording medium disk, to read and write head, signal processing system, a magnetic head and disk mechanical driving system. After more than 10 years of research, and with the new material unceasingly produces, hard drive size has been from the beginning of the14 inch decreases gradually to 3.5 inches,2.5 inches and1.8 inches. As a hard disk drive magnetic head core components, smaller size, higher precision, better performance. As the head performance is improved, the processing and welding method is put forward just got requirements. In the quality of the head and the PCB board welding is used in laser welding. Laser welding, the energy density required is low, as long as the processing area of the workpiece burn, and the adhesive can be together. Therefore, can reduce the laser output power. According to the different forms of joint, the laser welding can also be divided into docking, termination, direct connection, deep penetration fusion welding. Laser welding can be used with either the pulse welding, can also be used for continuous welding. Laser welding has the advantages as follows: illumination time is short, the welding process is rapid, not only improve productivity, but also the heat affected zone of pin, is not easy to be oxidized, suitable for welding of heat sensitive materials; laser welding without welding slag, also do not need to remove the oxide film, can be through the glass in a vacuum, applicable to miniature machine instrumentation welding; laser welding working range, can achieve a variety of material connection, such as ceramics metal connection. At the same time ,welding fixture design can improve the efficiency and precision of magnetic head welding, so it has high economical benefit.

Key words: laser; spot welding; magnetic head; fixture

目 录

引言 ...........................................................................................................................1

1 绪论 ...........................................................................................................................2

1.1 设计研究的目的和意义..................................................................................2

1.2 激光点焊机的应用与发展...............................................................................2

1.3 设计拟解决的关键问题...................................................................................4

2 焊接工件磁头的简介............................................................................................5

2.1 硬盘驱动器结构 .......... .................................................................................5

2.2 硬盘驱动器工作原理.....................................................................................6

2.4 磁头种类简介 ................................................................................................8

2.5 磁头材料 ........................................................................................................9

3 焊接方式激光点焊 ............................................................................................12

3.1 激光锡球焊接过程优化 ...............................................................................12

4 焊接夹具的设计 . ................................................................................................24

4.1 夹具的一般特性 ...........................................................................................24

4.2 夹具设计方案的确定 ................................................................................26

4.3 拉伸弹簧设计步骤 .........................................................................................37

4.1 定位误差分析 .........................................................................................41

参考文献 ......................................................................................................................44

谢辞 ................................................................................................................................45