设计简介

摘要

棉花营养钵育苗移栽是具有中国特色的植棉手段之一,在我国内陆棉区已得到较大规模的推广应用。实现棉花机械化精密播种是进行棉花工厂化制钵育苗的关键,但是近些年来,对棉花种子尤其是光籽棉种机械化精播的研究及相关设备几乎是空白。本文在对多种播种装置的比较研究的基础上,提出了电磁振动式棉花精密播种的思想。

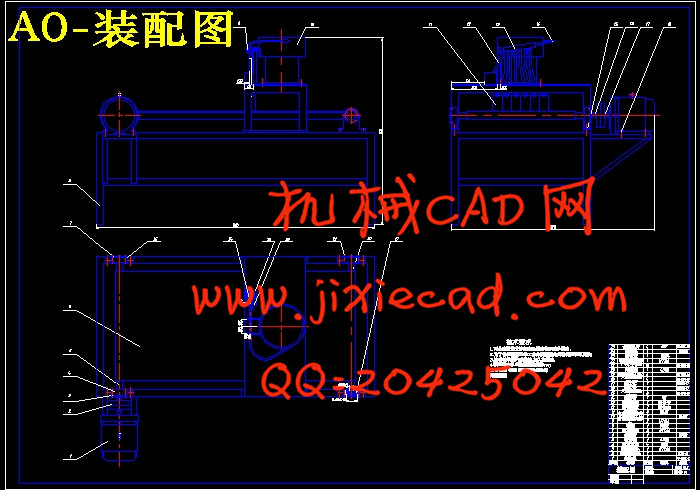

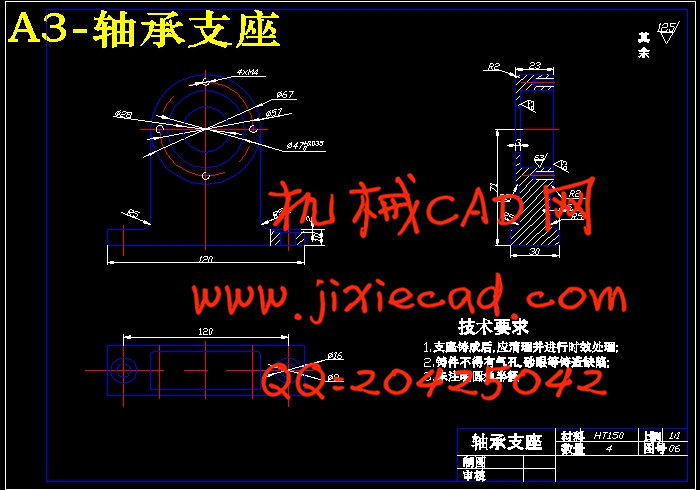

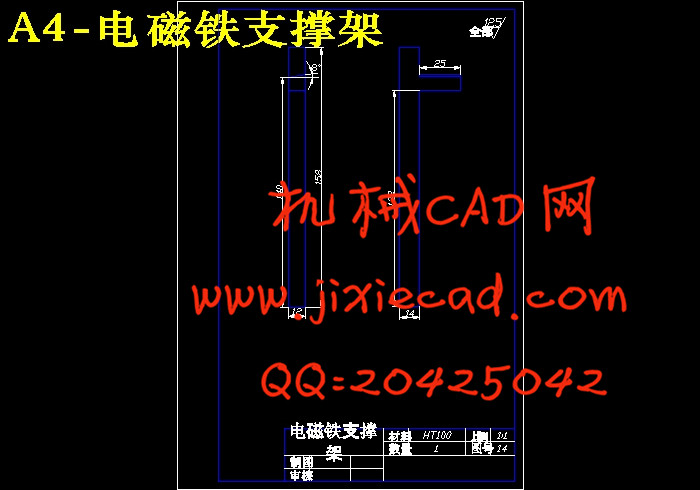

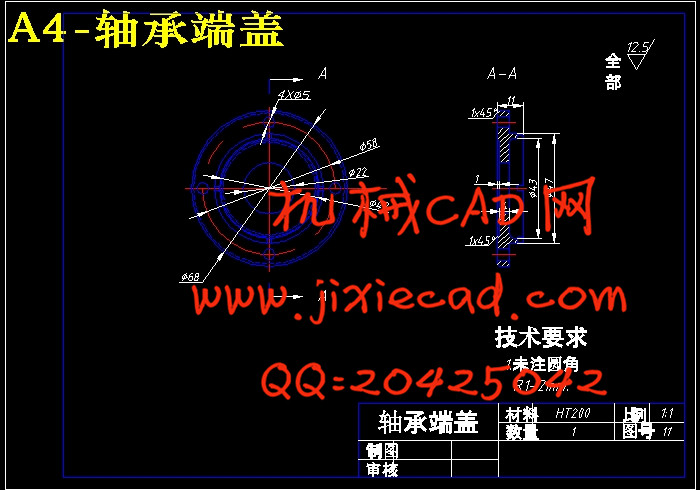

为了实现光籽棉种的单粒精播,设计了电磁振动式棉花精密播种装置,该装置主要包括电磁振动排种器、分流回收装置和钵盘输送机构。通过对电磁振动排种器工作原理的分析,得出了实现种子连续前移的条件,在此基础上完成了对电磁振动排种器的参数选择,在保证棉种单列有序排列的前提下,完成了排种盘基本结构尺寸的结构设计;根据棉种的形状尺寸设计出了孔的形状尺寸和分流装置的结构形式。应用PLC编程技术,控制各个工作机构的协调顺序动作,实现了种子的单粒精密播种。

为了使得排种装置能够以一种较好的排种速度进行排种,在实验室里较为理想的条件下,进行了大量的试验,找出了影响排种速度的因素,得出了排种速度随着它们的变化规律,确定了它们的取值范围。在此基础上,通过正交试验,分析了分流通道倾角、输出电压和工作频率对播种质量(单粒率、空穴率)的影响效果,得到了它们的最优组合,给出了各个指标随三个因素的变化规律。

关键词:棉花 电磁振动 精密播种 控制

ABSTRACT

棉花营养钵育苗移栽是具有中国特色的植棉手段之一,在我国内陆棉区已得到较大规模的推广应用。实现棉花机械化精密播种是进行棉花工厂化制钵育苗的关键,但是近些年来,对棉花种子尤其是光籽棉种机械化精播的研究及相关设备几乎是空白。本文在对多种播种装置的比较研究的基础上,提出了电磁振动式棉花精密播种的思想。

为了实现光籽棉种的单粒精播,设计了电磁振动式棉花精密播种装置,该装置主要包括电磁振动排种器、分流回收装置和钵盘输送机构。通过对电磁振动排种器工作原理的分析,得出了实现种子连续前移的条件,在此基础上完成了对电磁振动排种器的参数选择,在保证棉种单列有序排列的前提下,完成了排种盘基本结构尺寸的结构设计;根据棉种的形状尺寸设计出了孔的形状尺寸和分流装置的结构形式。应用PLC编程技术,控制各个工作机构的协调顺序动作,实现了种子的单粒精密播种。

为了使得排种装置能够以一种较好的排种速度进行排种,在实验室里较为理想的条件下,进行了大量的试验,找出了影响排种速度的因素,得出了排种速度随着它们的变化规律,确定了它们的取值范围。在此基础上,通过正交试验,分析了分流通道倾角、输出电压和工作频率对播种质量(单粒率、空穴率)的影响效果,得到了它们的最优组合,给出了各个指标随三个因素的变化规律。

关键词:棉花 电磁振动 精密播种 控制

ABSTRACT

Growing and transplanting seedling of cotton, which is one of Chinese cotton planting methods has been widely applied and popularized throughout the cotton planting areas in our country. The key process of industrialized bowl-making and growing of cotton is the realization of mechanically precision seeding, but the study on the technology and equipment of mechanically precision seeding of cottonseed is still blank. In this paper, electromagnetic vibration precision theory used in cotton precision seeding was put forward firstly.

Electromagnetic vibration cotton precision seeder was designed to realize precision seeding of bare cottonseed. This seeder was composed of three parts, which were electromagnetic vibration feeder, diffluent device and bowl feeding device. Through theory analysis of the feeder, the continuous slippage condition of cottonseed was gained, which provided theory base for the design of electromagnetic vibration feeder. And on the base of ordinal single-line of cottonseed the structure dimensions of electromagnetic vibration feeder were got. According to the figure and dimension of cottonseed, the figure and dimension of hole and diffluent device was designed. PLC was applied to control the harmonious action of all working parts, and precision seeding was achieved.

A lot of experimental tests were carried out to find out the better feeding velocity, and the changing disciplinarian of feeding velocity along with the obliquity of diffluent device and output voltage was gained. Experimental tests were carried out to measure effects of several factors, including the obliquity of diffluent device and output voltage and the working frequency. According to the experimental data, the better level of the three variables, their better combination and the varied curves of performance index were received.

Key words: cotton;electromagnetic vibration;precision;seeding;control

目录

第1章 绪 论 1Electromagnetic vibration cotton precision seeder was designed to realize precision seeding of bare cottonseed. This seeder was composed of three parts, which were electromagnetic vibration feeder, diffluent device and bowl feeding device. Through theory analysis of the feeder, the continuous slippage condition of cottonseed was gained, which provided theory base for the design of electromagnetic vibration feeder. And on the base of ordinal single-line of cottonseed the structure dimensions of electromagnetic vibration feeder were got. According to the figure and dimension of cottonseed, the figure and dimension of hole and diffluent device was designed. PLC was applied to control the harmonious action of all working parts, and precision seeding was achieved.

A lot of experimental tests were carried out to find out the better feeding velocity, and the changing disciplinarian of feeding velocity along with the obliquity of diffluent device and output voltage was gained. Experimental tests were carried out to measure effects of several factors, including the obliquity of diffluent device and output voltage and the working frequency. According to the experimental data, the better level of the three variables, their better combination and the varied curves of performance index were received.

Key words: cotton;electromagnetic vibration;precision;seeding;control

目录

1.1研究的目的和意义 1

1.2 常见的几种精密播种装置 2

1.3 课题主要研究内容及关键点 3

1.3.1研究内容 3

1.3.2关键点 4

第2章 电磁振动式棉花精密播种装置的设计 4

2.1 电磁振动播种装置的整体设计方案 4

2.2电磁振动式棉花精密排种器的设计 5

2.2.1结构及工作原理 5

2.2.2 种子的受力分析 7

2.2.3 种子的运动分析 8

2.2.4排种器主要参数设计 10

2.2.5 排种盘基本结构尺寸 11

2.3.6 排种盘材料及尺寸确定 12

2.3.7 弹簧常数的确定 13

2.3 分流回收装置的设计 13

2.3.1分流通道的基本结构及动作过程 14

2.3.2 孔的设计 15

2.3.3 电磁铁和弹簧的选择 16

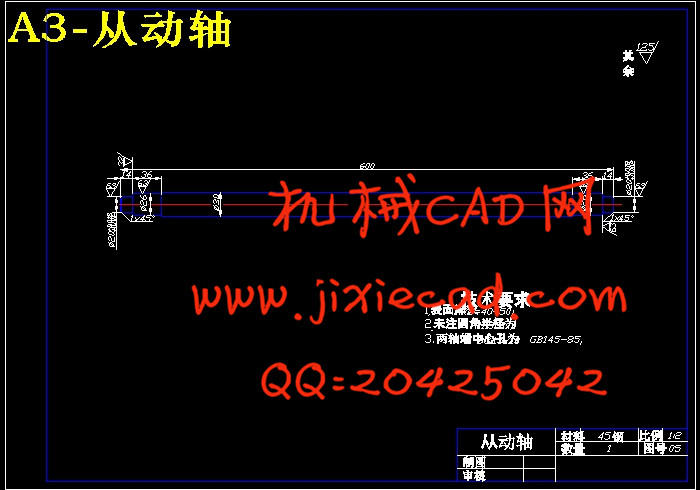

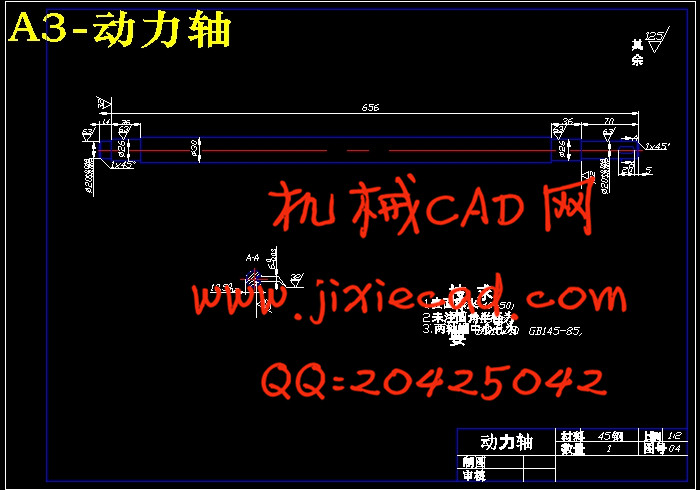

2.4 钵盘输送机构的设计 17

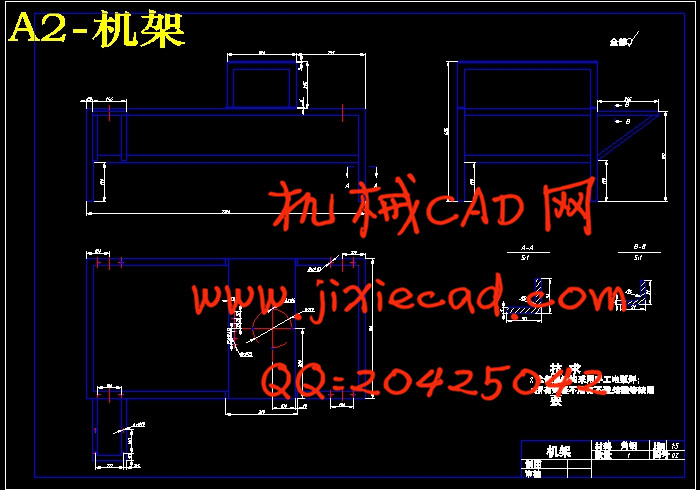

2.5机架的设计 18

2.6 其它附属设备 19

第3章 结 论 19

结束语 20

参考文献 21

致谢 22