设计简介

摘 要

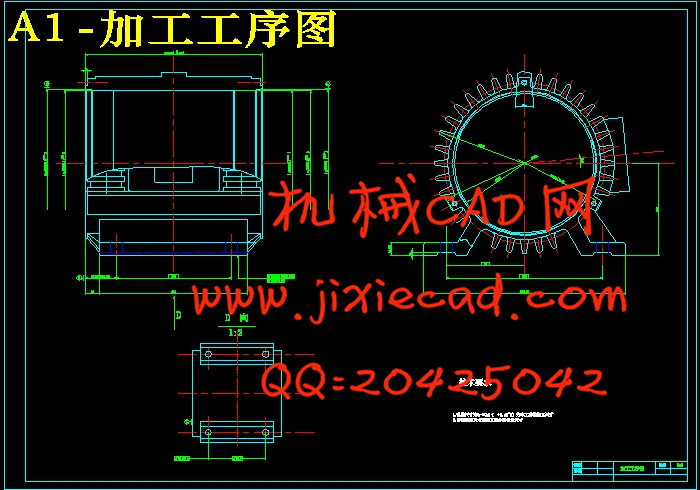

本文通过对电动机机座底面孔位的研究,为保证其底面上4个孔的位置公差,结合对组合机床的特点,设计出了专门用来加工该型号电动机机座底面底孔组合机床的多轴箱。

通过对通用机床多轴箱零件的研究,设计出了组合机床专用多轴箱,具有成本低,效率高的特点。组合机床设计时采用了“基准统一”的原则,以上一道加工工序的基准面为定位基准面,保证机座底面孔位的形状、位置精度的同时又降低了机座整体的累积误差。组合机床总体设计时采用了“三图一卡”的设计原则,既满足了加工要求,又保证了机床的相对生产率。

关键词:电动机机座 组合机床 多轴箱

ABSTRACT

Based on the study of position of underside of the electric motor frame, in order to ensure position tolerances of the 4 holes, combined with the characteristics of combination machine tool, this paper designs the multi-axle box of combination machine tool for underside of the electric motor frame.

Through the study of general machine tool spindle parts, the multi-axle box is designed with the advantages of low cost, high efficiency. The "Unification Datum" principle is taken into account the datum of the fixture is the one that last machining process used. In this way, the shape and position precision is ensured and reduces the accumulated error of the whole. The design principle of "three charts and a card" of the overall design of machine tool is used , not only to meet the processing requirements, but also to ensure the relative productivity of the machine tool.

Keyword: Electric motor frame Combination machine tool Multi-axle box

目 录

第一章 绪 论 1本文通过对电动机机座底面孔位的研究,为保证其底面上4个孔的位置公差,结合对组合机床的特点,设计出了专门用来加工该型号电动机机座底面底孔组合机床的多轴箱。

通过对通用机床多轴箱零件的研究,设计出了组合机床专用多轴箱,具有成本低,效率高的特点。组合机床设计时采用了“基准统一”的原则,以上一道加工工序的基准面为定位基准面,保证机座底面孔位的形状、位置精度的同时又降低了机座整体的累积误差。组合机床总体设计时采用了“三图一卡”的设计原则,既满足了加工要求,又保证了机床的相对生产率。

关键词:电动机机座 组合机床 多轴箱

ABSTRACT

Based on the study of position of underside of the electric motor frame, in order to ensure position tolerances of the 4 holes, combined with the characteristics of combination machine tool, this paper designs the multi-axle box of combination machine tool for underside of the electric motor frame.

Through the study of general machine tool spindle parts, the multi-axle box is designed with the advantages of low cost, high efficiency. The "Unification Datum" principle is taken into account the datum of the fixture is the one that last machining process used. In this way, the shape and position precision is ensured and reduces the accumulated error of the whole. The design principle of "three charts and a card" of the overall design of machine tool is used , not only to meet the processing requirements, but also to ensure the relative productivity of the machine tool.

Keyword: Electric motor frame Combination machine tool Multi-axle box

目 录

1.1课题的背景、目的及意义 1

1.2国内外组合机床的应用与发展现状 2

1.3本文要解决的问题、研究思路与基本框架 4

第二章 组合机床总体设计 6

2.1 机座底面加工工艺路线的制定 6

2.2 机座底面孔加工刀具的选择及切削用量的确定 8

2.2.1刀具的选择 9

2.2.2切削用量的确定 9

2.3 组合机床总体设计——三图一卡 10

2.3.1 被加工零件图的绘制 10

2.3.2 加工示意图的绘制 10

2.3.3 联系尺寸图的绘制 13

2.3.4 机床生产率计算卡的绘制 16

第三章 组合机床主轴箱设计 19

3.1 绘制多轴箱设计原始依据图 19

3.2 主轴结构型式的选择及动力计算 19

3.2.1 主轴结构型式和直径的选择 19

3.2.2 齿轮模数的初步确定 20

3.2.3 多轴箱的动力计算 20

3.3 传动系统的设计与计算 21

3.3.1 主轴分布类型及传动系统设计 21

3.3.2 各传动齿轮参数的计算 22

3.3.3 传动轴尺寸的确定 22

3.3.4 传动系统的校核 23

总 结 25

参考文献 25

致 谢 27