设计简介

摘 要: 介绍了电火花成型机床的加工原理、特点及其发展历程:它是通过脉冲直流电源不断产生火花放电来去除工件材料,且在工件与工具之间有绝缘液体介质。

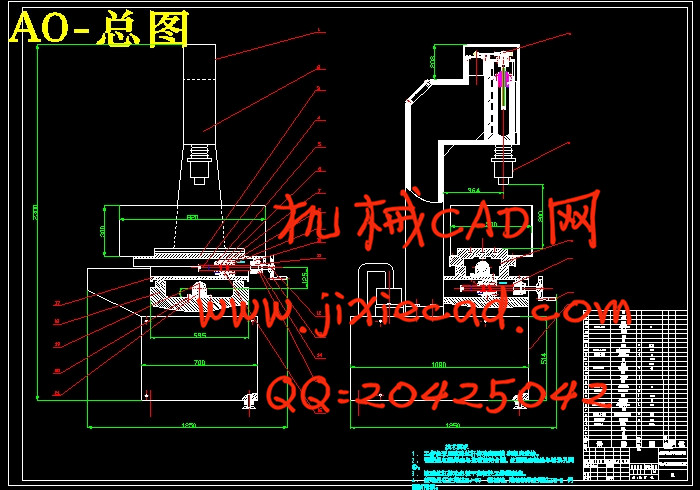

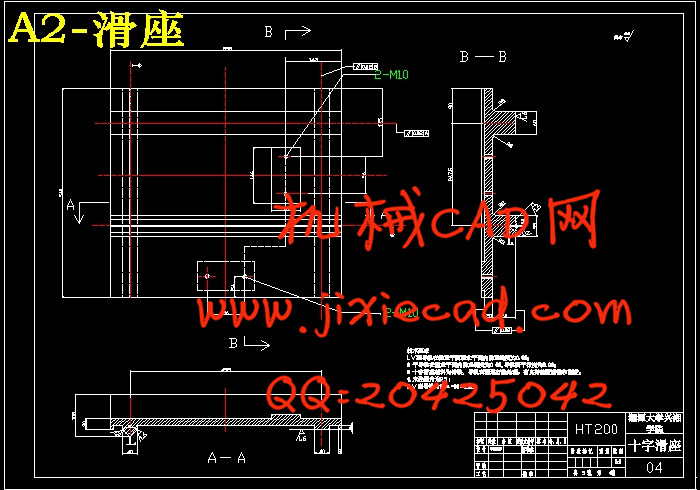

分析并设计了电火花成型机床结构系统。机床总体布局为单柱立式,主轴采用步进电机拖动滚珠丝杆完成升降,利用步进电机多级可变细分技术,实现伺服系统的变频、变步距双重伺服调节,提高系统的跟踪能力和稳定性。进给系统采用滚珠丝杆和十字滑座实现工作台的横向、纵向移动,运动平稳。

电火花成形加工要在加工精度、加工效率、加工范围等方面取得重大突破,一个重要的发展方向就是对机床成形运动方式的创新和多样化。本课题的研究,是对电火花成型加工发展方向的一次有益尝试,通过改进电火花加工机床的伺服系统、控制系统、机床结构等,在保证加工精度的前提下提高了加工效率;通过开放式的控制系统,提高了电火花成型加工过程的自动化。

关键词:电火花; 主轴; 滚珠丝杆; 十字滑座; V型导轨

Abstract: The processing principles, characteristics and development process of the EDM machine by author is introdunced in this paper. It removes material with repetitive spark discharges from a pulsating DC power supply, with a dielectric flowing between the work piece and the tool.

Analysis and design the system of structure for EDM machine . Machine overall layout as a single vertical column, 3-axis; Stepper motor is used in the machine tool to drive the ball screew up and down directly,the control system of the machinetool acapt divided dreving technique of step motor,and realizes dual regulations with changing feed step and changing feed frequency ,this improves its tracking ablity and stability. Feed system uses Ball Screw and the cross slide take the table move on the horizontal and vertical , smooth motion.

EDM should be in the processing accuracy, processing efficiency, processing and other aspects of the scope of a major breakthrough, an important direction of development is the right tool forming movement pattern of innovation and diversification. The study of this topic is a direction of development of EDM machining a useful attempt, by improving EDM servo systems, control systems, machine tool structure, guarantee the processing precision under the premise of improving the processing efficiency; through open the control system to improve the EDM process automation.

Keywords: EDM;main spindle;ball screw;Cross slide;V-shaped guideways

中文摘要 ·································································1

英文摘要 ·································································2

一、引言 ································································3

1.1 题研究的目的和意义················································3

1.2 本设计国内外研究历史与现状 ·······································4

1.3 本设计拟解决的关键问题和研究方法··································5

1.4 电火花成型加工特点和适用范围······································5

二、 电火花成型机床总体结构设计 ·····································8

2.1 电火花成型机的结构 形式···········································8

2.2 电火花成型机结构设计···············································9

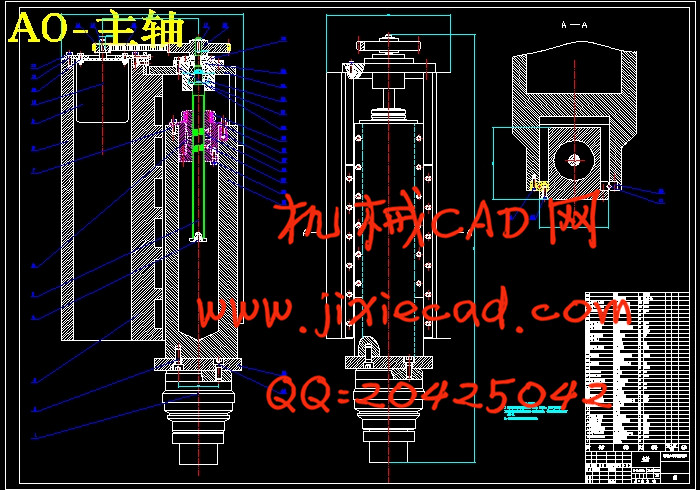

三、 主轴系统设计······················································13

3.1 主轴系统设计方案··················································13

3.2 电机的选择 ·······················································14

3.3 同步齿形带设计 ···················································19

3.4 滚珠丝杆副的设计··················································22

3.5 直线导轨的设计 ···················································27

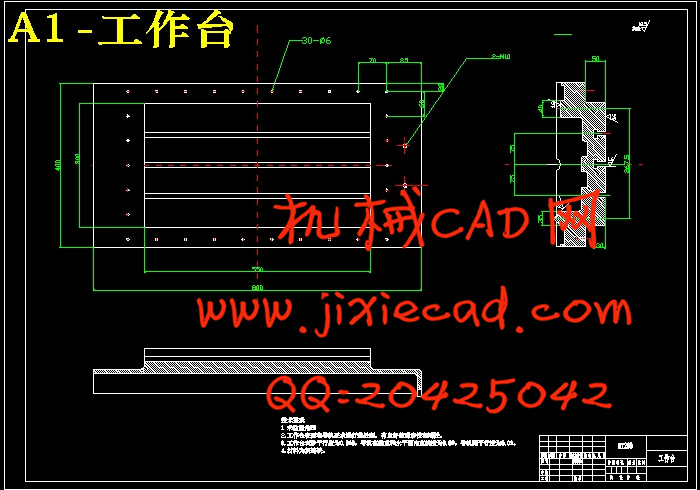

四、工作台设计 ························································29

五、十字滑座设计······················································34

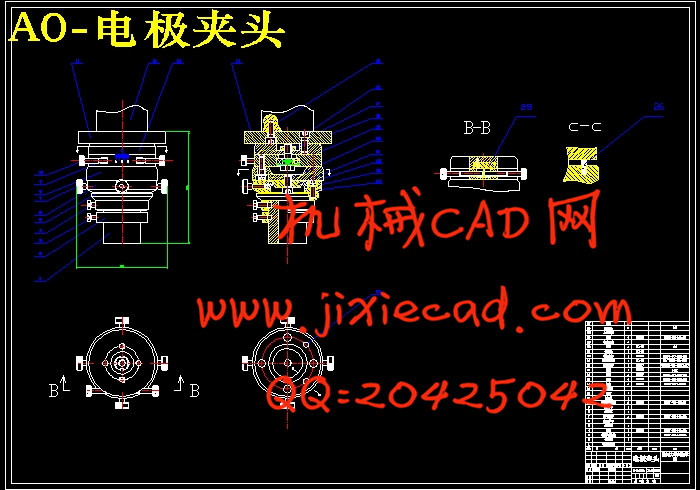

六、电极夹头设计·······················································37

七、机床润滑系统设计 ·················································40

八、工作液循环装置结构设计 ··········································42

参考文献·······························································.45

谢辞 ···································································46

分析并设计了电火花成型机床结构系统。机床总体布局为单柱立式,主轴采用步进电机拖动滚珠丝杆完成升降,利用步进电机多级可变细分技术,实现伺服系统的变频、变步距双重伺服调节,提高系统的跟踪能力和稳定性。进给系统采用滚珠丝杆和十字滑座实现工作台的横向、纵向移动,运动平稳。

电火花成形加工要在加工精度、加工效率、加工范围等方面取得重大突破,一个重要的发展方向就是对机床成形运动方式的创新和多样化。本课题的研究,是对电火花成型加工发展方向的一次有益尝试,通过改进电火花加工机床的伺服系统、控制系统、机床结构等,在保证加工精度的前提下提高了加工效率;通过开放式的控制系统,提高了电火花成型加工过程的自动化。

关键词:电火花; 主轴; 滚珠丝杆; 十字滑座; V型导轨

Abstract: The processing principles, characteristics and development process of the EDM machine by author is introdunced in this paper. It removes material with repetitive spark discharges from a pulsating DC power supply, with a dielectric flowing between the work piece and the tool.

Analysis and design the system of structure for EDM machine . Machine overall layout as a single vertical column, 3-axis; Stepper motor is used in the machine tool to drive the ball screew up and down directly,the control system of the machinetool acapt divided dreving technique of step motor,and realizes dual regulations with changing feed step and changing feed frequency ,this improves its tracking ablity and stability. Feed system uses Ball Screw and the cross slide take the table move on the horizontal and vertical , smooth motion.

EDM should be in the processing accuracy, processing efficiency, processing and other aspects of the scope of a major breakthrough, an important direction of development is the right tool forming movement pattern of innovation and diversification. The study of this topic is a direction of development of EDM machining a useful attempt, by improving EDM servo systems, control systems, machine tool structure, guarantee the processing precision under the premise of improving the processing efficiency; through open the control system to improve the EDM process automation.

Keywords: EDM;main spindle;ball screw;Cross slide;V-shaped guideways

中文摘要 ·································································1

英文摘要 ·································································2

一、引言 ································································3

1.1 题研究的目的和意义················································3

1.2 本设计国内外研究历史与现状 ·······································4

1.3 本设计拟解决的关键问题和研究方法··································5

1.4 电火花成型加工特点和适用范围······································5

二、 电火花成型机床总体结构设计 ·····································8

2.1 电火花成型机的结构 形式···········································8

2.2 电火花成型机结构设计···············································9

三、 主轴系统设计······················································13

3.1 主轴系统设计方案··················································13

3.2 电机的选择 ·······················································14

3.3 同步齿形带设计 ···················································19

3.4 滚珠丝杆副的设计··················································22

3.5 直线导轨的设计 ···················································27

四、工作台设计 ························································29

五、十字滑座设计······················································34

六、电极夹头设计·······················································37

七、机床润滑系统设计 ·················································40

八、工作液循环装置结构设计 ··········································42

参考文献·······························································.45

谢辞 ···································································46