设计简介

摘 要

机械化运送越来越广泛的得到应用,近年来已成为发展最迅速的行业之一在机械化输送的领域里,链条输送既能实现垂直,水平,倾斜,弯曲及相互组合的各种输送轨迹,又能适应散装,带装等各种类型的物料搬运;既能满足运行平稳,低速输送和节拍可控的自动化生产先的工况要求,又能在恶劣的环境里可靠的工作,链条输送机作为性能良好的连续输送机,它可以不停的在同一方向运输物料,装卸无须停机,具有很高的生产率. 由于链条输送机供料均匀与运行速度稳定,工作过程中消耗的功率变化不大,因而驱动装置功率较小 链条输送机的重要功能元件是输送链,而链条的结构是千变万化的,所以链条输送机能适用于众多的使用环境和众多的使用要求.与带传动相比, 链传动没有弹性滑动和打滑,能保持准确的平均传动比,传动尺寸比较紧凑,不需要很大的张紧力,作用在轴上的载荷也小;承载能力大;效率高 ,如果温度较高,在这样的环境下如果我们采用带传动,带子的寿命会很短,而且实际情况会更糟,采用齿轮传动,可能情况也没什么差别, 在低速运行大中心距的情况下,与齿轮传动相比,链传动能吸振与缓和冲击,结构简单,加工成本低廉,安装精度要求低.

关键词:自动化 输送机 链条 平稳

Abstract

Mechanization transit more and more extensive get application, have become in recent years develop the most quick profession one in mechanize transport field in, chain transport can realize vertical, level, incline , bend and make up mutually various transport locus, can again meet bulk, take pack wait for the stock of various types carry ; can satisfy operation steady, transport at low speed may control with metre automation production the late requirement of operating mode, again can in bad environment in reliable work, chain conveyer is performance good continuous conveyer, it need not stop in same one side to transportation stock, load and unload need not stop machine, have very high productivity. Since chain conveyer is let , expects , is even , is steady with traversal speed, the power change that consumed in working process is not large , thus the power of actuating device less prick Jia Lu suddenly make noise signboard sheath Lu earth the structure of chain is ever changing, so chain conveyer can apply to numerous use environment and numerous use ask . compare with , chain transmission with tape transmission have no elasticity slide with hit slippery, can maintain accurate average transmission compare than, transmission size compact, do not need great tensile force, take affect in axle on load also little; bearing capacity big; efficiency is positive drive high , if temperature higher, in such environment take off if we can be the condition of big central distance at low speed short very much with the life of tape transmission and belt, also actual condition can go bad more, adopt , possible condition also sink what difference, in run compare with , chain transmission with positive drive can inhale shake lash with mitigation, structure simple, finished cost cheap, installation precision requirement low.

Keyword: Automize Conveyer. Roller chain . Steady

目 录

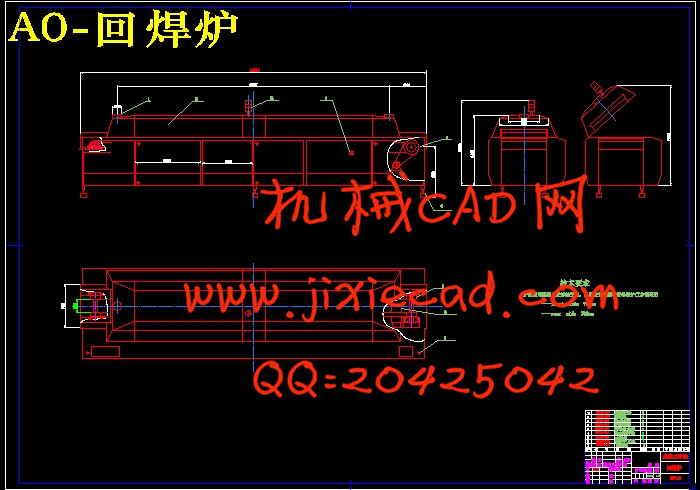

0前言…………………………………………………………………………………… 1

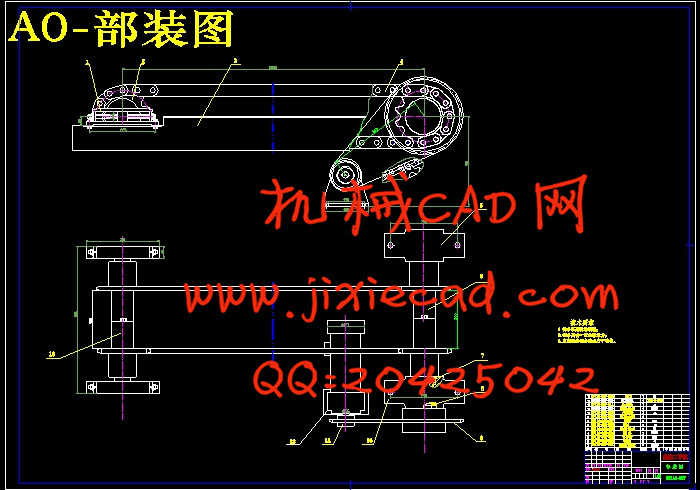

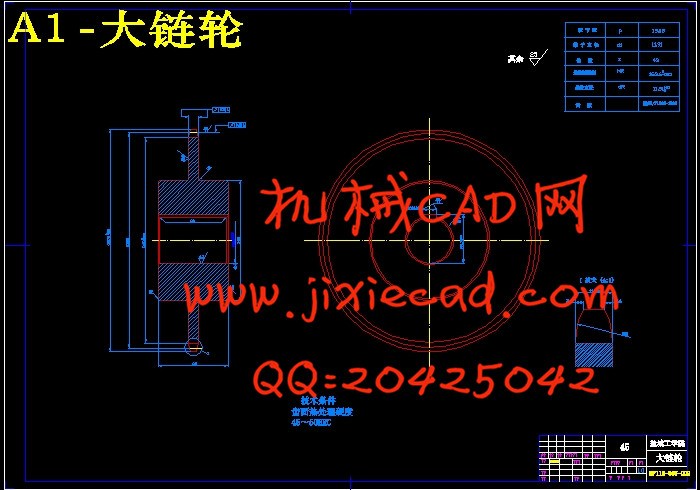

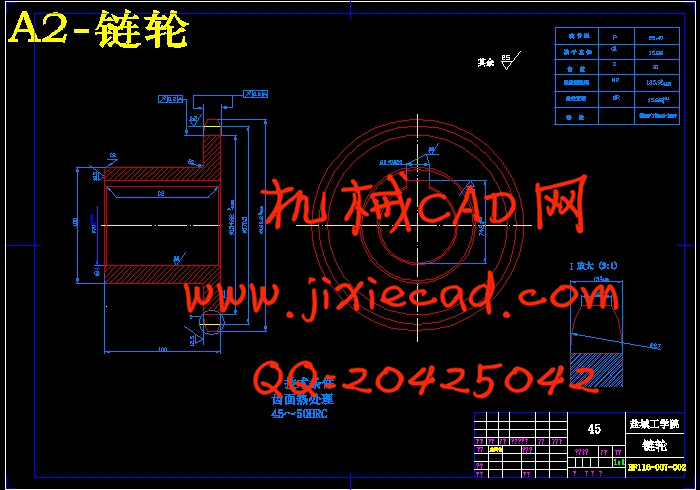

1.传输链轮的设计…………………………………………………………………… 3

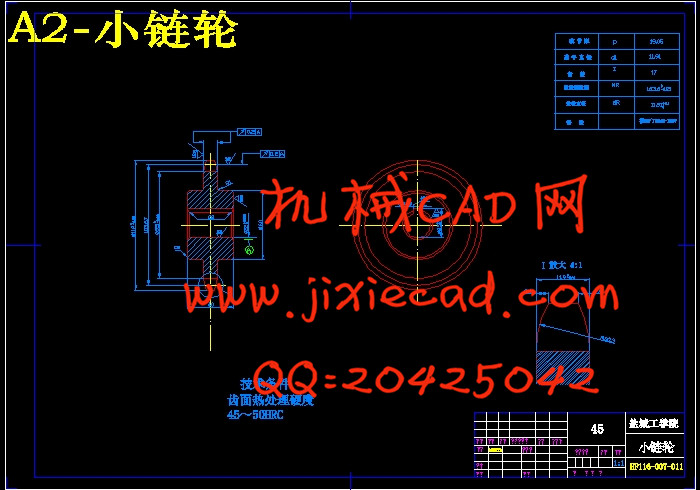

2.传输链轮的设计……………………………………………………………………… 5

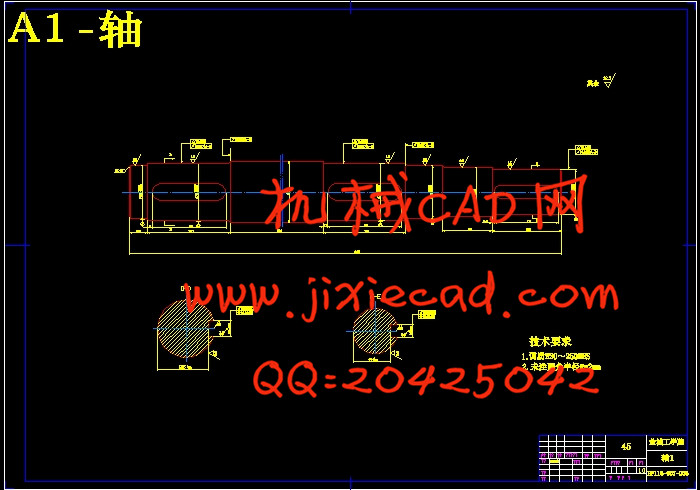

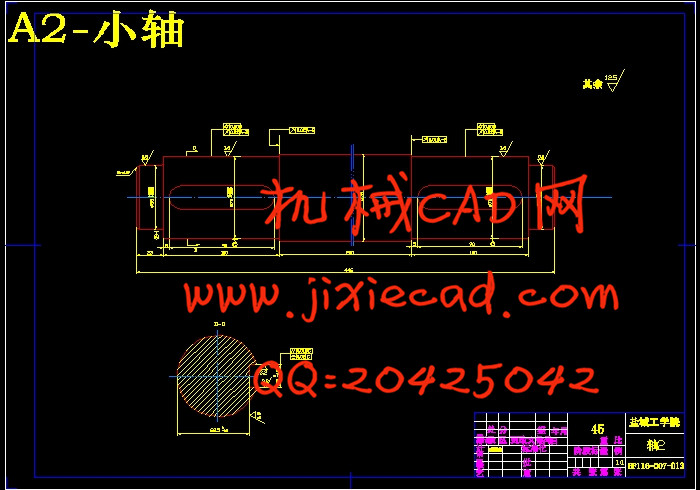

3.传动轴的校核…………………………………………………………………… 7

4.比较其他方案…………………………………………………………………… 10

5.温度控制系统……………………………………………………………………… 12

6.结论…………………………………………………………………………………… 20

7.致谢……………………………………………………………………………………… 21

参考文献……………………………………………………………………………………22

附件清单……………………………………………………………………………………23

机械化运送越来越广泛的得到应用,近年来已成为发展最迅速的行业之一在机械化输送的领域里,链条输送既能实现垂直,水平,倾斜,弯曲及相互组合的各种输送轨迹,又能适应散装,带装等各种类型的物料搬运;既能满足运行平稳,低速输送和节拍可控的自动化生产先的工况要求,又能在恶劣的环境里可靠的工作,链条输送机作为性能良好的连续输送机,它可以不停的在同一方向运输物料,装卸无须停机,具有很高的生产率. 由于链条输送机供料均匀与运行速度稳定,工作过程中消耗的功率变化不大,因而驱动装置功率较小 链条输送机的重要功能元件是输送链,而链条的结构是千变万化的,所以链条输送机能适用于众多的使用环境和众多的使用要求.与带传动相比, 链传动没有弹性滑动和打滑,能保持准确的平均传动比,传动尺寸比较紧凑,不需要很大的张紧力,作用在轴上的载荷也小;承载能力大;效率高 ,如果温度较高,在这样的环境下如果我们采用带传动,带子的寿命会很短,而且实际情况会更糟,采用齿轮传动,可能情况也没什么差别, 在低速运行大中心距的情况下,与齿轮传动相比,链传动能吸振与缓和冲击,结构简单,加工成本低廉,安装精度要求低.

关键词:自动化 输送机 链条 平稳

Abstract

Mechanization transit more and more extensive get application, have become in recent years develop the most quick profession one in mechanize transport field in, chain transport can realize vertical, level, incline , bend and make up mutually various transport locus, can again meet bulk, take pack wait for the stock of various types carry ; can satisfy operation steady, transport at low speed may control with metre automation production the late requirement of operating mode, again can in bad environment in reliable work, chain conveyer is performance good continuous conveyer, it need not stop in same one side to transportation stock, load and unload need not stop machine, have very high productivity. Since chain conveyer is let , expects , is even , is steady with traversal speed, the power change that consumed in working process is not large , thus the power of actuating device less prick Jia Lu suddenly make noise signboard sheath Lu earth the structure of chain is ever changing, so chain conveyer can apply to numerous use environment and numerous use ask . compare with , chain transmission with tape transmission have no elasticity slide with hit slippery, can maintain accurate average transmission compare than, transmission size compact, do not need great tensile force, take affect in axle on load also little; bearing capacity big; efficiency is positive drive high , if temperature higher, in such environment take off if we can be the condition of big central distance at low speed short very much with the life of tape transmission and belt, also actual condition can go bad more, adopt , possible condition also sink what difference, in run compare with , chain transmission with positive drive can inhale shake lash with mitigation, structure simple, finished cost cheap, installation precision requirement low.

Keyword: Automize Conveyer. Roller chain . Steady

目 录

0前言…………………………………………………………………………………… 1

1.传输链轮的设计…………………………………………………………………… 3

2.传输链轮的设计……………………………………………………………………… 5

3.传动轴的校核…………………………………………………………………… 7

4.比较其他方案…………………………………………………………………… 10

5.温度控制系统……………………………………………………………………… 12

6.结论…………………………………………………………………………………… 20

7.致谢……………………………………………………………………………………… 21

参考文献……………………………………………………………………………………22

附件清单……………………………………………………………………………………23