设计简介

摘 要

去年以来,我国专用车市场取得较好的经营业绩,全国395家改装车企业改装汽车23.06万辆,销售23.05万辆。自卸汽车27125辆,占总量的11.76%。其中中型自卸车占据了很大比重,因为我国是农业大国,因此中型自卸车是具有中国特色的“国情车”,主要应用地区是广大农村及建筑行业,消费对象是广大农民及建筑工地,功能是以县、乡级道路短途运输为主,其他作业为辅,专门为乡镇道路设计。

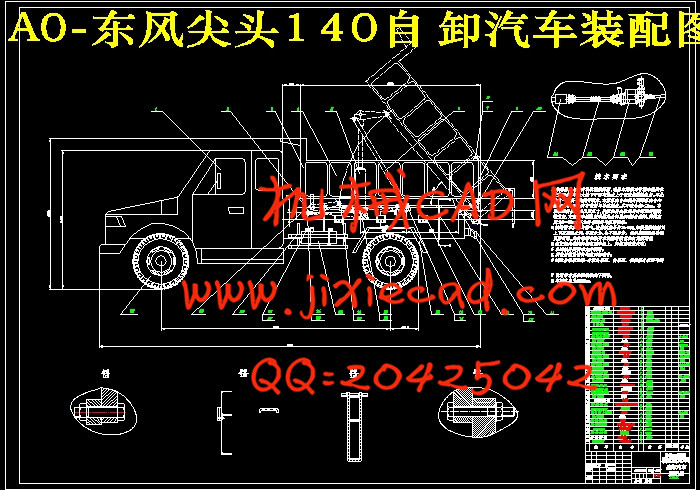

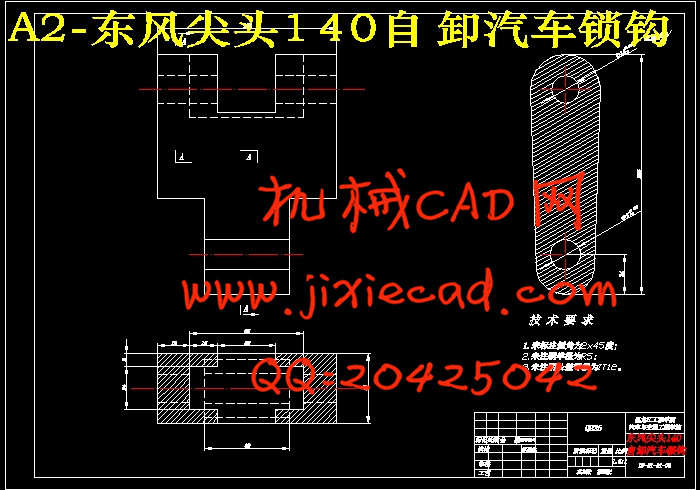

本人通过对市场上出现的各种中型自卸汽车的车厢和举升机构进行了较详细地了解,确认了东风尖头140自卸汽车的车厢和举升机构的设计方案,较好地解决了自卸车设计和制造成本较高的问题,给生产、改装自卸汽车的生产企业提供了一种新思路。本文首先对自卸车的设计特点以及国内外发展现状做了相关的概述。接着,从车厢的设计、举升机构的设计、液压系统的设计等方面进行了东风尖头140自卸车的总体设计。其中,车厢设计主要有外形及自动开闭机构的设计,举升机构设计中对举升机构进行了运动分析和受力分析,然后在液压系统设计中,对其工作原理进行了说明并通过计算得出合理的液压装置。最后对自卸车副车架进行了设计。

关键字:自卸汽车 ;车厢 ;副车架;举升机构;液压系统

ABSTRACT

Since last year, our country private car market has obtained the good operating results, the national 395 stock car enterprises re-equips automobile 230,600, sells 230,500. Dump truck 27125, account for the total quantity 11.76%. And the medium dump truck occupied the very great proportion, because our country is the large agricultural nation, therefore the medium dump truck has the Chinese characteristic “the national condition vehicle”, mainly applies the area is the general countrysides and the building profession, expends the object is the general farmers and the Construction site, the function is by the county, the township level path short haul primarily, other works for auxiliary, specially for villages and towns road design. Myself through each kind of medium dump truck's compartment which and the lifting organization appeared to the market in carry on had understood in detail that confirmed the east wind tip 140 dump truck's compartments and the lifting organization's design proposal, has solved the dump truck design and the production cost high question well, for the production, the re-equipping dump truck's Production enterprise has provided one kind of new mentality. This article first has made the related outline to dump truck's design feature as well as the domestic and foreign development present situation. Then, from compartment's design, lifting organization's design, hydraulic system's aspects and so on design has carried on the east wind tip 140 dump truck's system designs. And, the compartment design mainly had the contour and the automatic switching mechanism design, in the lifting organization design has carried on the movement analysis and the stress analysis to the lifting organization, then in the hydraulic system design, has carried on the explanation to its principle of work and obtains the reasonable hydraulic unit through the computation. Finally has carried on the design to the dump truck sub-frame.

Key words:Dump truck; Compartment; Sub-frame; Lifting mechanism; Hydraulic system

目 录

摘要Ⅰ

Abstract.Ⅱ

第1章 绪 论 1

1.1 课题的提出 1

1.2 课题来源及研究意义 3

1.3 自卸汽车国内外研究概况及发展趋势 4

1.4 研究的内容 7

第2章 整车参数的确定及校核 9

2.1二类底盘的选择及校核 9

2.1.1 整车尺寸参数的确定 10

2.1.2总体布局的设计 12

2.1.3取力器布置方案的选定 12

2.1.4整车性能分析 16

2.2本章小结. 24

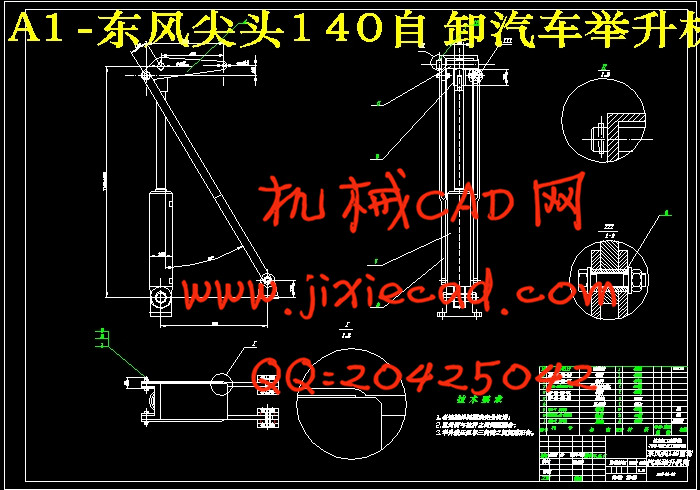

第3章 液压举升机构的设计 25

3.1 液压举升机构时应满足的性能 25

3.2 举升系统性能主要评价参数 26

3.3 液压举升机构方案的确定 27

3.3.1 液压举升机构简述 27

3.3.2 液压举升机构方案的选择 30

3.4 举升机构几何尺寸的确定 30

3.4.1 举升机构安装位置的设计 31

3.4.2三角臂的设计 32

3.4.3 拉杆长度的设计计算 33

3.5力学计算与校核 33

3.5.1 机构的坐标计算 33

3.5.2 机构受力分析 35

3.5.3 拉杆截面尺寸的确定 36

3.6 本章小结 37

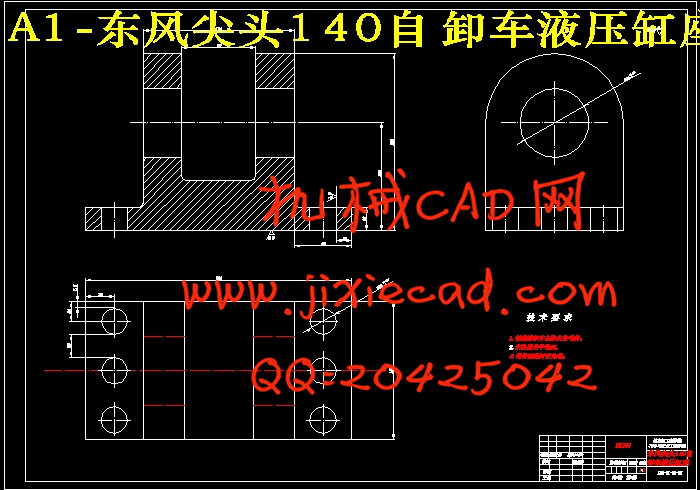

第4章 液压系统的计算 38

4.1液压油缸性能参数计算 38

4.2 液压泵性能参数计算 38

4.3油箱容积与油管内径计算 40

4.4系统压力校核 41

4.5车厢升降时间的校核 41

4.6液压分配阀 42

4.7操纵方式的选择 44

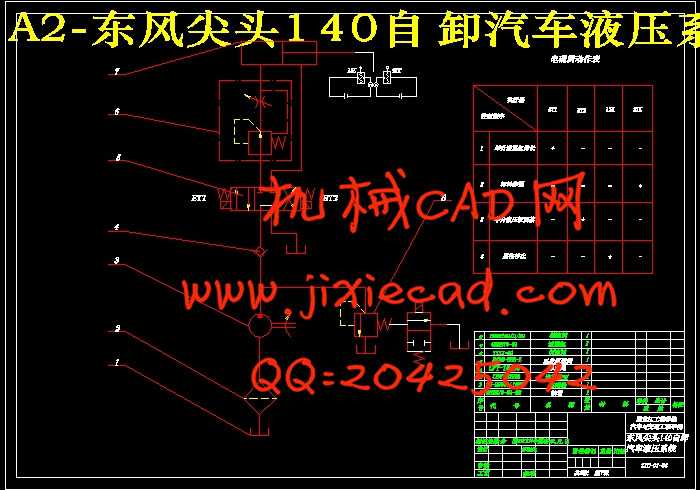

4.8液压系统原理及液压系统结构布置 44

4.9本章小结 45

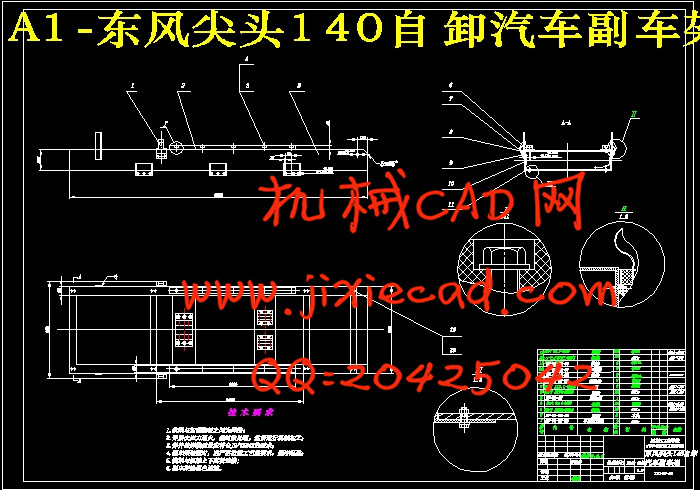

第5章 副车架与车厢及其附件的设计 46

5.1 选用的底盘主车架的主要尺寸 46

5.2副车架的结构设计 46

5.2.1副车架的外形 46

5.2.2副车架的选材 46

5.2.3 副车架的截面形状 47

5.2.4 加强板的布置 48

5.2.5 副车架的前端形状及安装位置 48

5.2.6 纵梁与横梁的连接设计 50

5.3 副车架与主车架的连接设计 51

5.4副车架尺寸的确定 52

5.5副车架的强度刚度弯曲适应性校核 52

5.6车厢形式的选择 58

5.7车厢的选材 59

5.8车厢的设计规范及尺寸确定 60

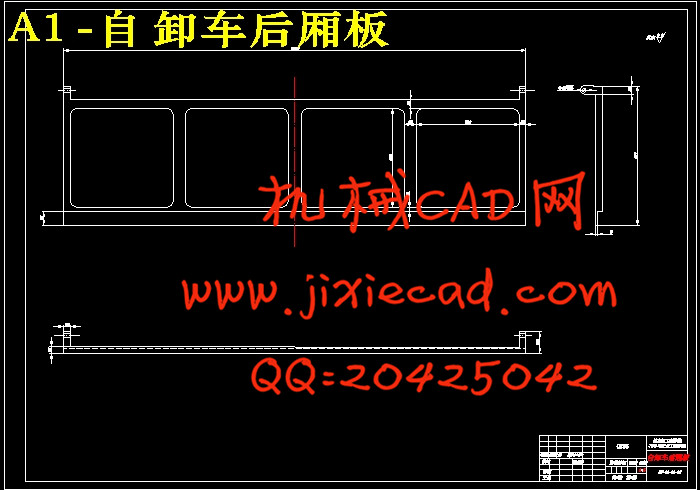

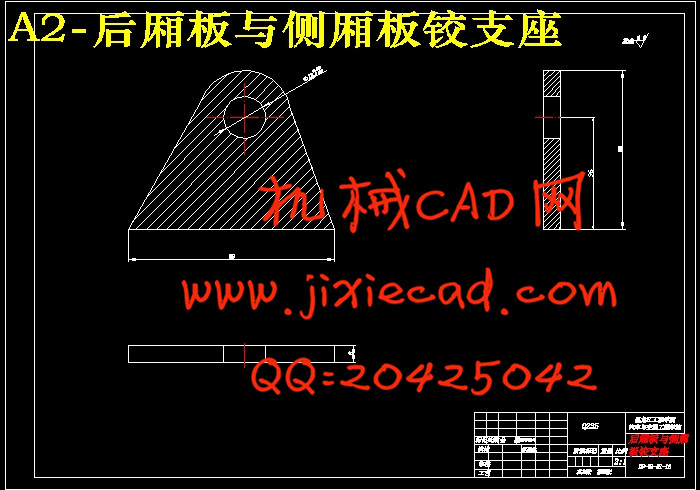

5.9车厢后拦板开合机构设计与分析 61

5.10本章小结 62

结 论 63

参考文献 64

致 谢 65

去年以来,我国专用车市场取得较好的经营业绩,全国395家改装车企业改装汽车23.06万辆,销售23.05万辆。自卸汽车27125辆,占总量的11.76%。其中中型自卸车占据了很大比重,因为我国是农业大国,因此中型自卸车是具有中国特色的“国情车”,主要应用地区是广大农村及建筑行业,消费对象是广大农民及建筑工地,功能是以县、乡级道路短途运输为主,其他作业为辅,专门为乡镇道路设计。

本人通过对市场上出现的各种中型自卸汽车的车厢和举升机构进行了较详细地了解,确认了东风尖头140自卸汽车的车厢和举升机构的设计方案,较好地解决了自卸车设计和制造成本较高的问题,给生产、改装自卸汽车的生产企业提供了一种新思路。本文首先对自卸车的设计特点以及国内外发展现状做了相关的概述。接着,从车厢的设计、举升机构的设计、液压系统的设计等方面进行了东风尖头140自卸车的总体设计。其中,车厢设计主要有外形及自动开闭机构的设计,举升机构设计中对举升机构进行了运动分析和受力分析,然后在液压系统设计中,对其工作原理进行了说明并通过计算得出合理的液压装置。最后对自卸车副车架进行了设计。

关键字:自卸汽车 ;车厢 ;副车架;举升机构;液压系统

ABSTRACT

Since last year, our country private car market has obtained the good operating results, the national 395 stock car enterprises re-equips automobile 230,600, sells 230,500. Dump truck 27125, account for the total quantity 11.76%. And the medium dump truck occupied the very great proportion, because our country is the large agricultural nation, therefore the medium dump truck has the Chinese characteristic “the national condition vehicle”, mainly applies the area is the general countrysides and the building profession, expends the object is the general farmers and the Construction site, the function is by the county, the township level path short haul primarily, other works for auxiliary, specially for villages and towns road design. Myself through each kind of medium dump truck's compartment which and the lifting organization appeared to the market in carry on had understood in detail that confirmed the east wind tip 140 dump truck's compartments and the lifting organization's design proposal, has solved the dump truck design and the production cost high question well, for the production, the re-equipping dump truck's Production enterprise has provided one kind of new mentality. This article first has made the related outline to dump truck's design feature as well as the domestic and foreign development present situation. Then, from compartment's design, lifting organization's design, hydraulic system's aspects and so on design has carried on the east wind tip 140 dump truck's system designs. And, the compartment design mainly had the contour and the automatic switching mechanism design, in the lifting organization design has carried on the movement analysis and the stress analysis to the lifting organization, then in the hydraulic system design, has carried on the explanation to its principle of work and obtains the reasonable hydraulic unit through the computation. Finally has carried on the design to the dump truck sub-frame.

Key words:Dump truck; Compartment; Sub-frame; Lifting mechanism; Hydraulic system

目 录

摘要Ⅰ

Abstract.Ⅱ

第1章 绪 论 1

1.1 课题的提出 1

1.2 课题来源及研究意义 3

1.3 自卸汽车国内外研究概况及发展趋势 4

1.4 研究的内容 7

第2章 整车参数的确定及校核 9

2.1二类底盘的选择及校核 9

2.1.1 整车尺寸参数的确定 10

2.1.2总体布局的设计 12

2.1.3取力器布置方案的选定 12

2.1.4整车性能分析 16

2.2本章小结. 24

第3章 液压举升机构的设计 25

3.1 液压举升机构时应满足的性能 25

3.2 举升系统性能主要评价参数 26

3.3 液压举升机构方案的确定 27

3.3.1 液压举升机构简述 27

3.3.2 液压举升机构方案的选择 30

3.4 举升机构几何尺寸的确定 30

3.4.1 举升机构安装位置的设计 31

3.4.2三角臂的设计 32

3.4.3 拉杆长度的设计计算 33

3.5力学计算与校核 33

3.5.1 机构的坐标计算 33

3.5.2 机构受力分析 35

3.5.3 拉杆截面尺寸的确定 36

3.6 本章小结 37

第4章 液压系统的计算 38

4.1液压油缸性能参数计算 38

4.2 液压泵性能参数计算 38

4.3油箱容积与油管内径计算 40

4.4系统压力校核 41

4.5车厢升降时间的校核 41

4.6液压分配阀 42

4.7操纵方式的选择 44

4.8液压系统原理及液压系统结构布置 44

4.9本章小结 45

第5章 副车架与车厢及其附件的设计 46

5.1 选用的底盘主车架的主要尺寸 46

5.2副车架的结构设计 46

5.2.1副车架的外形 46

5.2.2副车架的选材 46

5.2.3 副车架的截面形状 47

5.2.4 加强板的布置 48

5.2.5 副车架的前端形状及安装位置 48

5.2.6 纵梁与横梁的连接设计 50

5.3 副车架与主车架的连接设计 51

5.4副车架尺寸的确定 52

5.5副车架的强度刚度弯曲适应性校核 52

5.6车厢形式的选择 58

5.7车厢的选材 59

5.8车厢的设计规范及尺寸确定 60

5.9车厢后拦板开合机构设计与分析 61

5.10本章小结 62

结 论 63

参考文献 64

致 谢 65