设计简介

摘 要

众所周知,制造业是国民经济的基础产业和支柱产业,是推动国家技术进步的力量。我国制造业较落后,想要改变此现状就必须提高制造业装备水平,特别是机床的数控化率。数控机床是属于高新技术集成的机电一体化机械加工设备,受到世界各工业发达国家的高度重视。因此,磨床机电一体化设计成为热点。本文设计了端面磨床X向进给运动的设计,主要完成了:整体结构设计,X向的结构设计计算、滚珠丝杠、直线导轨的选择及其强度分析;以步进电机为进给驱动的驱动系统及其传动机构的分析设计计算。

关键词:磨床,端面磨床,进给运动,直线导轨

Abstract

As everyone knows, the manufacturing industry is the fundamental industry of national economy and pillar industry, is to promote the national technology progress power. Manufacturing industry of our country is more backward, want to change this situation, we must improve the manufacturing level of equipment, especially machine tool NC rate. CNC machine tool is a high-tech integrated mechanical and electrical integration of mechanical processing equipment, has developed industrial countries attach great importance to. Therefore, the grinder design of electromechanical integration has become a hot.This paper introduces the design of end face grinder X to feed movement design, mainly to complete the design of the overall structure,: X to structural design calculation, the ball screw, linear guide the selection and strength analysis; the stepping motor as drive driving system and driving mechanism analysis and design calculation.

Key Words: Grinder, surface grinder, feed motion, linear guide

目 录

摘 要 IAbstract II

目 录 III

第1章 绪论 5

1.1 磨床加工范围 5

1.2 磨床发展历程 5

1.3磨床的分类 6

1.4安全防护 7

1.5 端面磨床 8

第2章 端面磨床课题设计任务及要求 8

2.1 端面磨床的设计任务要求 8

2.2 课题设计途径与方法 9

第3章 端面磨床总体设计方案 9

3.1 端面磨床总体设计 9

3.2 总体设计注意事项 10

3.3 端面磨床总体布局设计 10

3.3.1 加工零件 10

3.3.2 初步估计组成部分 10

3.3.3 总体布局初步设计 10

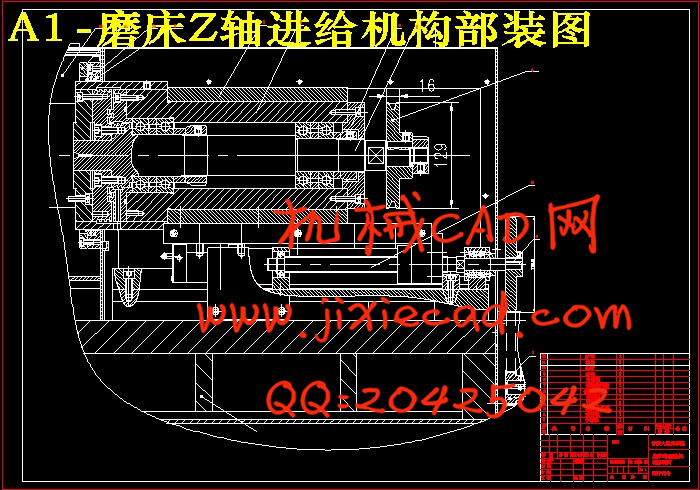

第4章 端面磨床X进给机构设计 11

4.1 丝杠传动系统的设计计算 11

4.1滚珠丝杠优点 11

4.2丝杠选型 11

4.2.1滚珠丝杠副导程的确定 11

4.2.2滚珠丝杠副的传动效率 11

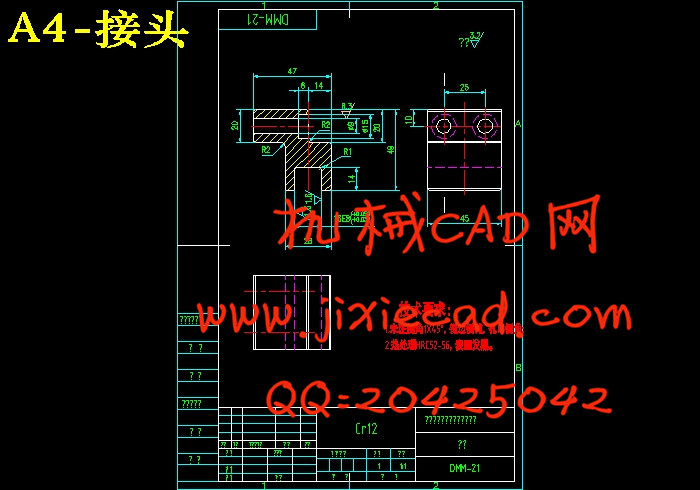

4.3联轴器选取 12

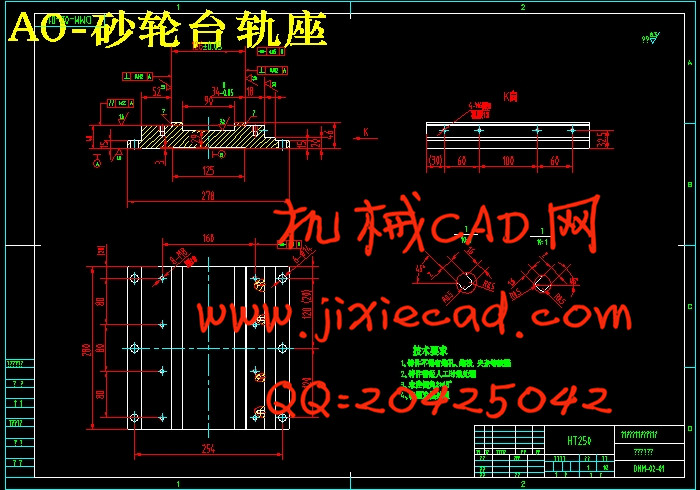

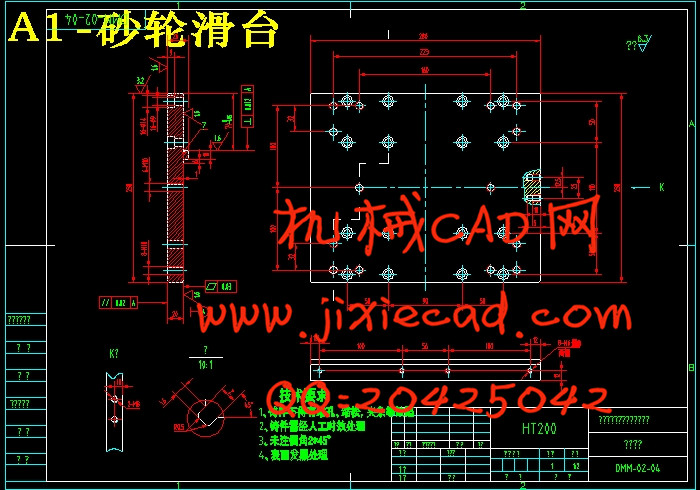

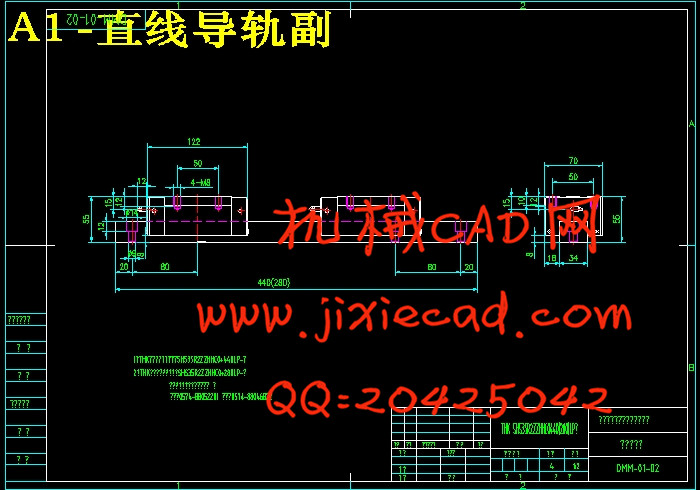

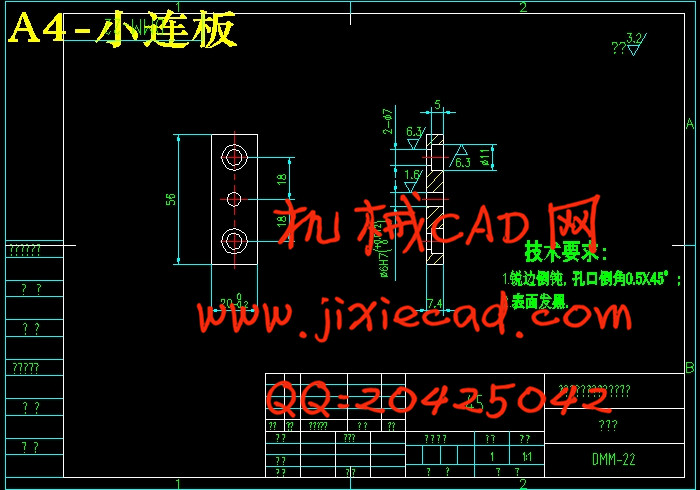

4.4导轨的选型 12

4.5滑动导轨的特点 15

4.6 滑动导轨的设计 16

总 结 19

致 谢 20

参考文献 21