设计简介

摘 要

此机械主要针对中小型用户,用于日常生产生活中对肉制品腌制加工的注射盐水部分,有结构简单,造价低廉,方便实用,易于推广等特点。

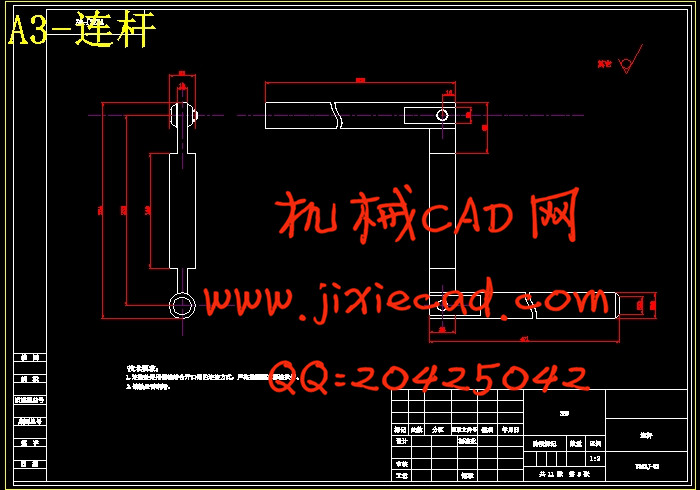

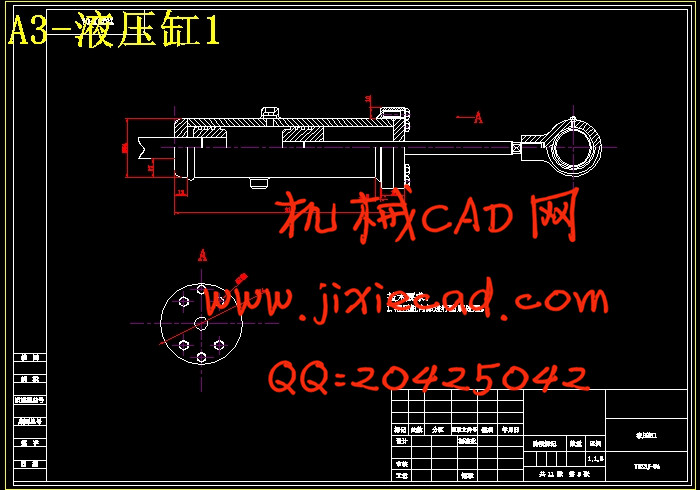

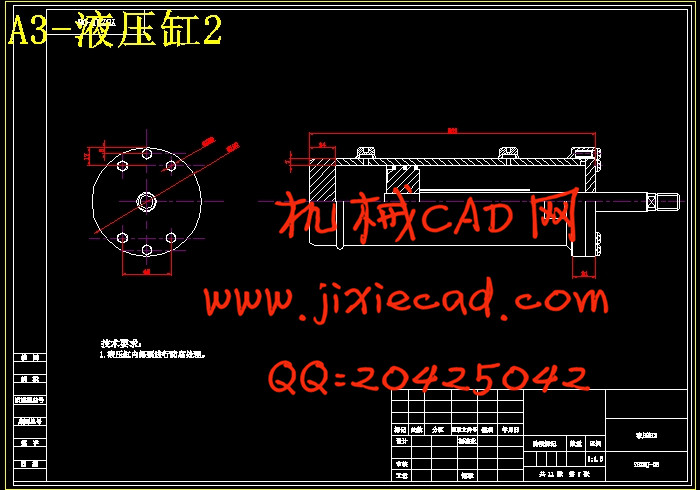

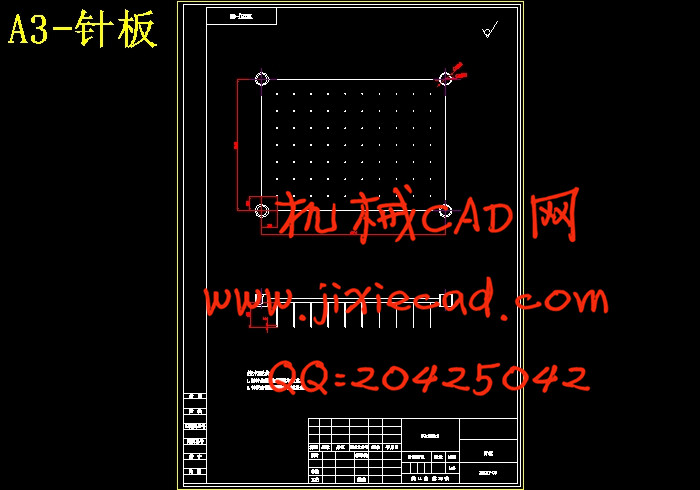

通过对各种以往的注射机构的分析,总结了注射机主要结构的特点,主要基于液压系统的设计,通过对各种液压零件的组装、利用,以及部分主要零件的再设计,来达到目的。本机械共分手动、自动两种方式,手动部分主要通过液压缸的内部活塞的运动,,从而带动液压缸下部分柱塞的运动,来带动针板的目的,来达到对盐水的吸入、注射等动作,通过手柄的行程限制装置来达到对液压缸内部吸入盐水量的限制,从而控制针板注入盐水体积及针头插入深度等的限制;电动部分主要通过位于机械下半部的液压系统的控制,通过液压缸二的参与来达到对针板的自动控制。

通过对本机械的研究,能够对液压系统有更充分的认识,运用一些简单的液压元件的组装就能够实现一些复杂的机械要求,本机械就是充分利用了此特点,能够充分应用的同时,又兼具有简单方便的特点。但是我们仍然能够看到本机械的不足,正是由于机械的简单化,使得在操作精度上不能达到太高的要求,而且由于自身的种种限制,不适于配合大批量腌制肉类产品的生产,只适用于小型生产的辅助。

Abstract

The main machinery for small and medium-sized users, for the production of day-to-day life of the marinated meat processing part of the saline injection, a simple structure, low cost, convenient and practical, easy to promote and so on.

Through the various agencies of the previous injection analysis, summarized the main structure of the injection machine characteristics, based primarily on the design of the hydraulic system, through the various parts of the hydraulic assembly, use, and some of the major components of the re-design, to achieve the arm. This machinery consists of manual, automatic two ways, mainly through the manual part of the internal hydraulic cylinder piston movement, and thus part of the hydraulic cylinder piston movement, to board the purpose-driven, to achieve the brine of Inhaled, injected, and other moves, the journey through the handle limit device to achieve the hydraulic cylinder internal saline inhalation of the restrictions, the control board into the drip needle the size and depth of needle inserted into the restrictions adopted by some of the major electrical machinery in the second half Hydraulic system of control, through the participation of two hydraulic cylinders to achieve on-board control.

Through the study of the mechanical, hydraulic systems are able to more fully understand and use some simple hydraulic components of the assembly will be able to achieve some complex mechanical requirements, the machinery is made full use of this feature can be fully applied at the same time, And a simple and convenient features. But we can still see the inadequacies of the machinery, it is precisely because of mechanical simplicity, makes the operation can not be achieved high precision on the request, and because of various restrictions on their own, with not suitable for mass production of marinated meat products Applies only to small-scale production support.

目 录

前 言 5

1 设计依据 6

2 方案设计(工作原理) 6

2.1 手动工作方式 6

2.2电动工作方式 7

3 设计计算 8

3.1 手柄的行程 8

3.2液压缸设计计算 10

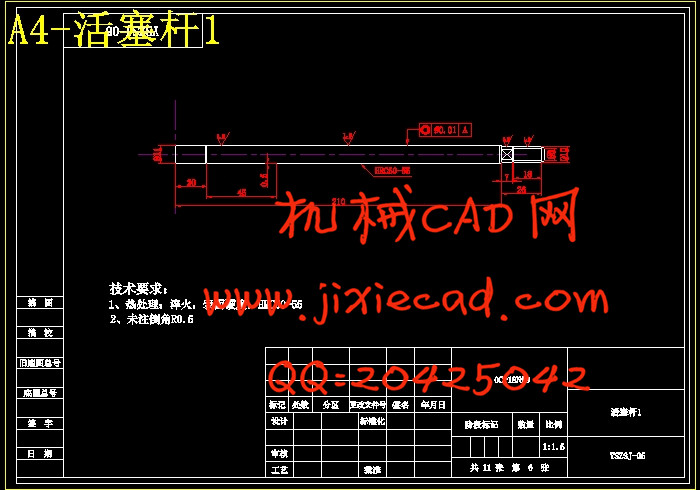

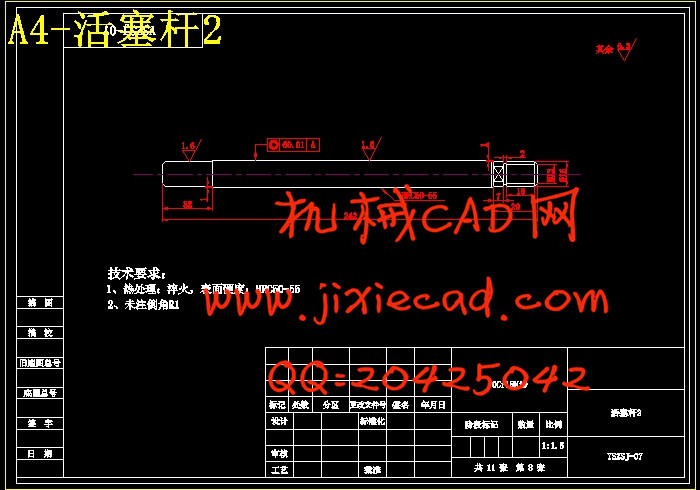

3.3活塞设计计算 10

3.4校核压杆稳定 10

3.5杠杆的强度计算 11

3.6连杆强度校核 11

3.7手柄强度校核 12

3.8销的强度校核 12

3.9 立柱的强度计算 13

3.10弹簧设计计算 14

3.11上下托板强度计算 15

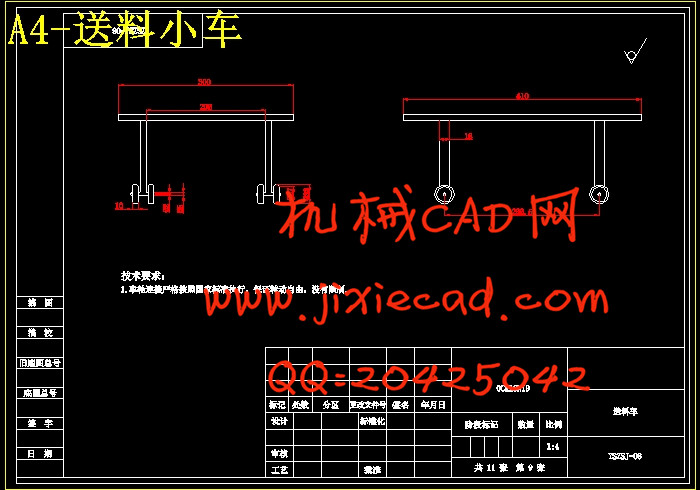

3.12 送料车导轨的设计及校核 15

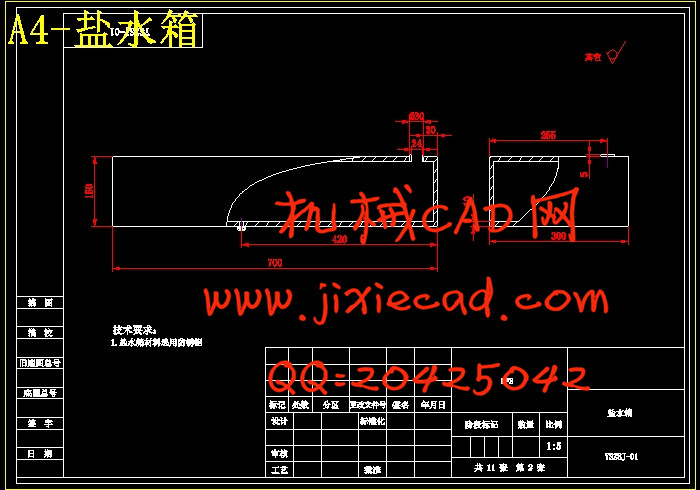

3.13 盐水箱的设计 15

3.14 滤清器与管接头的选择 16

4 电动方案主要部件选择 16

4.1 泵的选择 16

4.2 电动机的选择 16

4.3 溢流阀的选择 16

4.4 减压阀的选择 16

4.5 手动换向阀的选择 16

4.6 电磁换向阀的选择 16

4.7 联轴器的选择 16

4.8 单向阀的选择 17

5 盐水注射机的正确使用和维护 17

5.1 安全注意事项 17

5.2 安装注意事项 17

5.3 使用注意事项 17

5.4 维护注意事项 18

5.4.1 注射流不正确的可能诱因: 18

5.4.2 机器注射空气或产生泡沫: 18

5.4.3 液压泵制造出大的声音和无规律的噪音: 18

5.4.4 机器速度降低: 18

5.4.5 机器运转正常,但没有压力: 18

6 设 计 小 结 18

7 参 考 文 献 19

此机械主要针对中小型用户,用于日常生产生活中对肉制品腌制加工的注射盐水部分,有结构简单,造价低廉,方便实用,易于推广等特点。

通过对各种以往的注射机构的分析,总结了注射机主要结构的特点,主要基于液压系统的设计,通过对各种液压零件的组装、利用,以及部分主要零件的再设计,来达到目的。本机械共分手动、自动两种方式,手动部分主要通过液压缸的内部活塞的运动,,从而带动液压缸下部分柱塞的运动,来带动针板的目的,来达到对盐水的吸入、注射等动作,通过手柄的行程限制装置来达到对液压缸内部吸入盐水量的限制,从而控制针板注入盐水体积及针头插入深度等的限制;电动部分主要通过位于机械下半部的液压系统的控制,通过液压缸二的参与来达到对针板的自动控制。

通过对本机械的研究,能够对液压系统有更充分的认识,运用一些简单的液压元件的组装就能够实现一些复杂的机械要求,本机械就是充分利用了此特点,能够充分应用的同时,又兼具有简单方便的特点。但是我们仍然能够看到本机械的不足,正是由于机械的简单化,使得在操作精度上不能达到太高的要求,而且由于自身的种种限制,不适于配合大批量腌制肉类产品的生产,只适用于小型生产的辅助。

Abstract

The main machinery for small and medium-sized users, for the production of day-to-day life of the marinated meat processing part of the saline injection, a simple structure, low cost, convenient and practical, easy to promote and so on.

Through the various agencies of the previous injection analysis, summarized the main structure of the injection machine characteristics, based primarily on the design of the hydraulic system, through the various parts of the hydraulic assembly, use, and some of the major components of the re-design, to achieve the arm. This machinery consists of manual, automatic two ways, mainly through the manual part of the internal hydraulic cylinder piston movement, and thus part of the hydraulic cylinder piston movement, to board the purpose-driven, to achieve the brine of Inhaled, injected, and other moves, the journey through the handle limit device to achieve the hydraulic cylinder internal saline inhalation of the restrictions, the control board into the drip needle the size and depth of needle inserted into the restrictions adopted by some of the major electrical machinery in the second half Hydraulic system of control, through the participation of two hydraulic cylinders to achieve on-board control.

Through the study of the mechanical, hydraulic systems are able to more fully understand and use some simple hydraulic components of the assembly will be able to achieve some complex mechanical requirements, the machinery is made full use of this feature can be fully applied at the same time, And a simple and convenient features. But we can still see the inadequacies of the machinery, it is precisely because of mechanical simplicity, makes the operation can not be achieved high precision on the request, and because of various restrictions on their own, with not suitable for mass production of marinated meat products Applies only to small-scale production support.

目 录

前 言 5

1 设计依据 6

2 方案设计(工作原理) 6

2.1 手动工作方式 6

2.2电动工作方式 7

3 设计计算 8

3.1 手柄的行程 8

3.2液压缸设计计算 10

3.3活塞设计计算 10

3.4校核压杆稳定 10

3.5杠杆的强度计算 11

3.6连杆强度校核 11

3.7手柄强度校核 12

3.8销的强度校核 12

3.9 立柱的强度计算 13

3.10弹簧设计计算 14

3.11上下托板强度计算 15

3.12 送料车导轨的设计及校核 15

3.13 盐水箱的设计 15

3.14 滤清器与管接头的选择 16

4 电动方案主要部件选择 16

4.1 泵的选择 16

4.2 电动机的选择 16

4.3 溢流阀的选择 16

4.4 减压阀的选择 16

4.5 手动换向阀的选择 16

4.6 电磁换向阀的选择 16

4.7 联轴器的选择 16

4.8 单向阀的选择 17

5 盐水注射机的正确使用和维护 17

5.1 安全注意事项 17

5.2 安装注意事项 17

5.3 使用注意事项 17

5.4 维护注意事项 18

5.4.1 注射流不正确的可能诱因: 18

5.4.2 机器注射空气或产生泡沫: 18

5.4.3 液压泵制造出大的声音和无规律的噪音: 18

5.4.4 机器速度降低: 18

5.4.5 机器运转正常,但没有压力: 18

6 设 计 小 结 18

7 参 考 文 献 19