设计简介

摘要

液压缸是液压系统执行部分,它是一种压力流体的机械能来实现直线往复运动或往复摆动运动能量转换设备。液压缸根据其结构形式,可以分为两类,活塞式液压缸和活塞式液压缸。活塞式液压缸、活塞缸的出口压力和流量,输出的推力和进度。

因为主机和主机的液压缸机构有直接的联系,对于不同的主机和机构,不同的用途和工作条件的要求,液压缸的类型和结构是千变万化的,没有统一的规范,不象液压泵和液压阀已经标准化了,因此必须根据实际需要自行设计。

液压缸的设计,液压缸的基本原料是负载值,加载速度、中风、液压缸的结构和安装要求,液压缸的设计计算主要是确定液压缸的压力和流量的使用,和液压缸强度的组件检查和性能检查,等等。

液压缸的设计步骤:

⑴. 根据液压缸的工作特性,选择液压缸类型和安装方法。

⑵. 根据动力和运动分析,确定主要尺寸参数。

⑶. 设计主要零部件的结构。

⑷. 液压缸的性能计算。

液压缸的设计和使用正确与否,直接影响其性能,没有故障。在这方面,经常遇到液压缸安装不当,活塞杆在部分负荷下,液压缸或下垂活塞和活塞杆的压杆不稳定等等。在本设计中,充分考虑到了这些设计中应该注意的问题,并且针对液压缸两端需要焊接绞座的问题,对金属的可焊性进行了分析。

关键词:液压举重机;液压缸;活塞杆

Abstract

The hydraulic pressure jar is an execution component in the hydraulic pressure system, It is one kind transforms the liquid Mechanical energy to realize the straight line reciprocating movment or pressure reciprocation oscillating motion energy conversion installment. Hydraulic pressure jar according to their structure form , can divide into piston jar and post fill in two kinds of jars. The piston jar and the plunger jar input for the pressure and the current capacity, outputs for the thrust force and the speed.

Because the hydraulic pressure jar has direct contacts with job organization on host computer and host computer, Regarding different main engine and organization, along with use and operating mode request difference, hydraulic jar type and structure ever changing, does not have the unification the specification, Did not like Hydraulic pump and hydraulic valve already standardized, therefore had independently to design according to the actual need. Designs the hydraulic jar the basic firsthand information is the hydraulic jar load value, the load velocity of movement, the stroke value, the hydraulic jar structural style and installs the request and so on, The hydraulic jar Mainly is to determine the design calculation hydraulic jar the working pressure and the current capacity, and carry on the intensity Check and hydraulic performance jar spare part checking computations and so on.

Design step of the hydraulic pressure jar:

(1)According to the operating mode characteristic of the hydraulic pressure jar, choose the type of the hydraulic pressure jar and installation way.

(2)Analyse according to dynamical and movement, confirm the main size parameter

(3)Design the structure of the main spare part

(4)The performance of the hydraulic pressure jar is calculated

The hydraulic jar design and the use is correct or not, directly affects its performance and easy otherwise to break down. In this respect, Meet hydraulic pressure jar install improper, cylinder rod is lean towards year to bear, hydraulic pressure jar or piston flagging and cylinder rod keep pole mistake question such as being steady often. In this design, have fully considered the Problems should be paid attention to these designs, and needs to weld in view of the hydraulic jar beginnings and ends twists the place the question, has carried on the analysis to the metal weldability.

Key words: Perform component; Firsthand information;

Design procedure

目 录

第一章 引 言 1

1.1 国内外的发展状况 1

1.2 液压缸简介 4

第二章 设计计算 6

2.1液压缸的初步设计 6

2.1.1液压缸的工作压力 6

2.1.2 初选缸筒内径及活塞杆直径 7

2.2液压缸主要技术性能参数的计算 8

2.3液压缸的主要部件设计 8

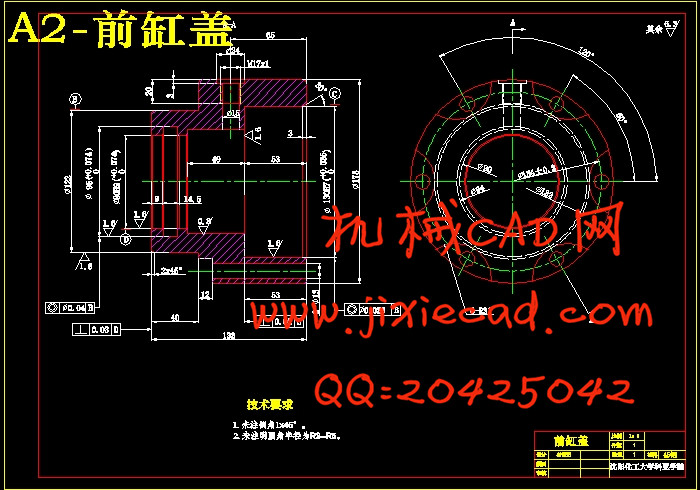

2.3.1 缸筒的设计 8

2.3.2 活塞的设计 10

2.3.3 活塞杆的设计 11

2.3.4 端盖上螺栓的校核 12

2.3.5 导向套的设计 14

2.3.6 缸筒底部厚度 15

2.3.7 密封圈的选用 15

2.3.8 开口销的选用 16

第三章 金属的可焊性 17

第四章 液压缸的选用 18

4.1 液压缸主要参数的确定 18

4.2 使用工况及安装条件的确定 18

4.3 缓冲装置的选用 18

4.4 密封件的选用 19

4.5 工作介质的选用 19

结 论 20

参考文献 21

致 谢 22

液压缸是液压系统执行部分,它是一种压力流体的机械能来实现直线往复运动或往复摆动运动能量转换设备。液压缸根据其结构形式,可以分为两类,活塞式液压缸和活塞式液压缸。活塞式液压缸、活塞缸的出口压力和流量,输出的推力和进度。

因为主机和主机的液压缸机构有直接的联系,对于不同的主机和机构,不同的用途和工作条件的要求,液压缸的类型和结构是千变万化的,没有统一的规范,不象液压泵和液压阀已经标准化了,因此必须根据实际需要自行设计。

液压缸的设计,液压缸的基本原料是负载值,加载速度、中风、液压缸的结构和安装要求,液压缸的设计计算主要是确定液压缸的压力和流量的使用,和液压缸强度的组件检查和性能检查,等等。

液压缸的设计步骤:

⑴. 根据液压缸的工作特性,选择液压缸类型和安装方法。

⑵. 根据动力和运动分析,确定主要尺寸参数。

⑶. 设计主要零部件的结构。

⑷. 液压缸的性能计算。

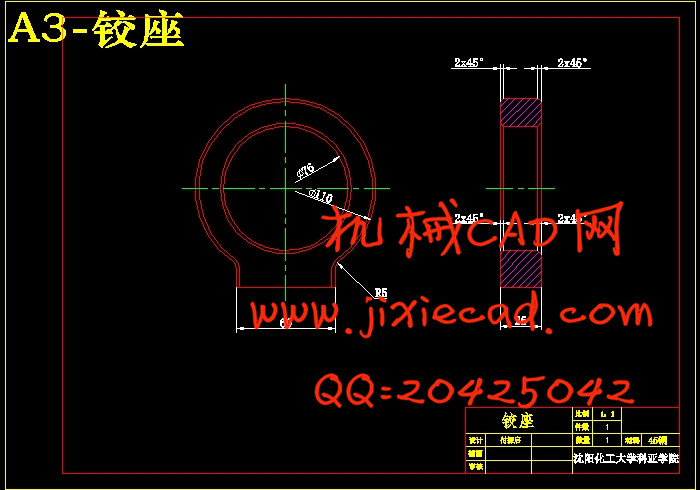

液压缸的设计和使用正确与否,直接影响其性能,没有故障。在这方面,经常遇到液压缸安装不当,活塞杆在部分负荷下,液压缸或下垂活塞和活塞杆的压杆不稳定等等。在本设计中,充分考虑到了这些设计中应该注意的问题,并且针对液压缸两端需要焊接绞座的问题,对金属的可焊性进行了分析。

关键词:液压举重机;液压缸;活塞杆

Abstract

The hydraulic pressure jar is an execution component in the hydraulic pressure system, It is one kind transforms the liquid Mechanical energy to realize the straight line reciprocating movment or pressure reciprocation oscillating motion energy conversion installment. Hydraulic pressure jar according to their structure form , can divide into piston jar and post fill in two kinds of jars. The piston jar and the plunger jar input for the pressure and the current capacity, outputs for the thrust force and the speed.

Because the hydraulic pressure jar has direct contacts with job organization on host computer and host computer, Regarding different main engine and organization, along with use and operating mode request difference, hydraulic jar type and structure ever changing, does not have the unification the specification, Did not like Hydraulic pump and hydraulic valve already standardized, therefore had independently to design according to the actual need. Designs the hydraulic jar the basic firsthand information is the hydraulic jar load value, the load velocity of movement, the stroke value, the hydraulic jar structural style and installs the request and so on, The hydraulic jar Mainly is to determine the design calculation hydraulic jar the working pressure and the current capacity, and carry on the intensity Check and hydraulic performance jar spare part checking computations and so on.

Design step of the hydraulic pressure jar:

(1)According to the operating mode characteristic of the hydraulic pressure jar, choose the type of the hydraulic pressure jar and installation way.

(2)Analyse according to dynamical and movement, confirm the main size parameter

(3)Design the structure of the main spare part

(4)The performance of the hydraulic pressure jar is calculated

The hydraulic jar design and the use is correct or not, directly affects its performance and easy otherwise to break down. In this respect, Meet hydraulic pressure jar install improper, cylinder rod is lean towards year to bear, hydraulic pressure jar or piston flagging and cylinder rod keep pole mistake question such as being steady often. In this design, have fully considered the Problems should be paid attention to these designs, and needs to weld in view of the hydraulic jar beginnings and ends twists the place the question, has carried on the analysis to the metal weldability.

Key words: Perform component; Firsthand information;

Design procedure

目 录

第一章 引 言 1

1.1 国内外的发展状况 1

1.2 液压缸简介 4

第二章 设计计算 6

2.1液压缸的初步设计 6

2.1.1液压缸的工作压力 6

2.1.2 初选缸筒内径及活塞杆直径 7

2.2液压缸主要技术性能参数的计算 8

2.3液压缸的主要部件设计 8

2.3.1 缸筒的设计 8

2.3.2 活塞的设计 10

2.3.3 活塞杆的设计 11

2.3.4 端盖上螺栓的校核 12

2.3.5 导向套的设计 14

2.3.6 缸筒底部厚度 15

2.3.7 密封圈的选用 15

2.3.8 开口销的选用 16

第三章 金属的可焊性 17

第四章 液压缸的选用 18

4.1 液压缸主要参数的确定 18

4.2 使用工况及安装条件的确定 18

4.3 缓冲装置的选用 18

4.4 密封件的选用 19

4.5 工作介质的选用 19

结 论 20

参考文献 21

致 谢 22