设计简介

摘要

聚氨酯全称为聚氨基甲酸酯 ,是主链上含有重复氨基甲酸酯基团的大分子化合物的统称。它是由有机二异氰酸酯或多异氰酸酯与二羟基或多羟基化合物加聚而成。聚氨酯大分子中除了氨基甲酸酯外 ,还可含有醚、酯、脲、缩二脲 ,脲基甲酸酯等基团。

聚氨酯成型机是通过对聚氨酯加热到熔融状态,再靠离心机的离心原理将熔融的聚氨酯输送到搅拌头。经过高速强烈搅拌,使之料液均匀而喷出,形成所需产品。而离心成型技术是利用离心力成型管状或空心筒状制品的方法。通过挤出机或专用漏斗将定量的液态树脂或树脂分散体注入旋转并加热的容器(即模具)中,使其绕单轴高速旋转(每分钟几十转到两千转),此时放入的物料即被离心力迫使分布在模具的近壁部位。在旋转的同时,放入的物料发生固化,随后视需要经过冷却或后处理即能取得制品。在成型增强塑料制品时还可同时加入增强性的填料。离心浇铸通常用的都是熔体粘度较小、热稳定性较好的热塑性塑料,如聚酰胺、聚乙烯、聚氨酯等。

离心成型时,聚氨酯填充模具型腔主要靠的是离心机旋转时产生的离心力。离心力与质量成正比,与离心机转速的平方成正比,与旋转半径成正比。因此,对某一规格的转子而言,聚氨酯的质量和旋转半径是一定的,所以离心力的大小仅与离心机的转速有关,增大或减少离心力,只须改变离心机的转速即可。

在离心成型时,聚氨酯除了受到自身的重力作用外,主要是靠离心力的作用来填充模具型腔的,其填充方式是先填充远离旋转中心的型腔的外部,然后逐渐向心部填充完毕。因有离心力的存在,且它比重力大得多,所以聚氨酯的填充能力要比重力成型时强,只要离心机转速适当,离心力的大小合适,生产出的转子的质量就一定比浇注成型时形成的转子要好得多。

关键词:聚氨酯;离心成型;滚筒

Abstract

Polyurethane full-called polyurethane, is the main chain contains repeating urethane groups of molecules, collectively. It is an organic diisocyanate or polyisocyanate or polyol with two hydroxyl addition polymerization is made. Polyurethane macromolecules in addition to urethane, it can also contain ether, ester, urea, biuret, urea-based groups such as ester.

Polyurethane polyurethane molding machine is heated to melt through the state to rely on the principle of centrifuge centrifuge transported to the melting of the polyurethane mixing head. After strong stirring speed, so that even the spray liquid, to form the desired product. The centrifugal molding technology is the use of centrifugal force forming tubular or hollow tubular products method.Through the extruder hopper or dedicated to quantitative liquid resin or resin dispersion into the rotation and heating container (ie, mold), making it rotate around the axis high-speed (tens of per minute to two thousand rpm), then put incurs centrifugal force into the material distributed in the mold wall parts. Rotating at the same time, into the material cures, and then as needed through the cooling or post-processing that is able to obtain products. Enhanced the molding plastic products can also added to enhance the nature of filler. Centrifugal casting melt viscosity are usually smaller, better thermal stability of thermoplastics such as polyamide, polyethylene, polyurethane, etc.

Centrifugal molding, polyurethane fill the mold cavity is the main centrifuge rotation by the centrifugal force generated. Centrifugal force is proportional with the quality, speed proportional to the square with the centrifuge, and the radius is proportional to. Therefore, a specification of the rotor, the polyurethane is a certain quality and radius, so the size of the centrifugal force only with the speed of the centrifuge, increase or reduce the centrifugal force, centrifuge speed can only change.

In centrifugal molding, polyurethane except by their own gravity, the centrifugal force depends mainly on the role to fill the mold cavity, the fill mode is first filling away from the center of rotation of the external cavity, and then gradually to the heart of the Department of Tianchong completed . Due to the presence of centrifugal force, gravity force and it is much larger, so the polyurethane molding filling capacity than gravity is strong, as long as the appropriate centrifuge speed, the centrifugal force of the right size to produce the quality of the rotor must be better than pouring molding form The rotor is much better.

Key words: polyurethane; centrifugal molding; drum

目 录

引言………………………………………………………………………1

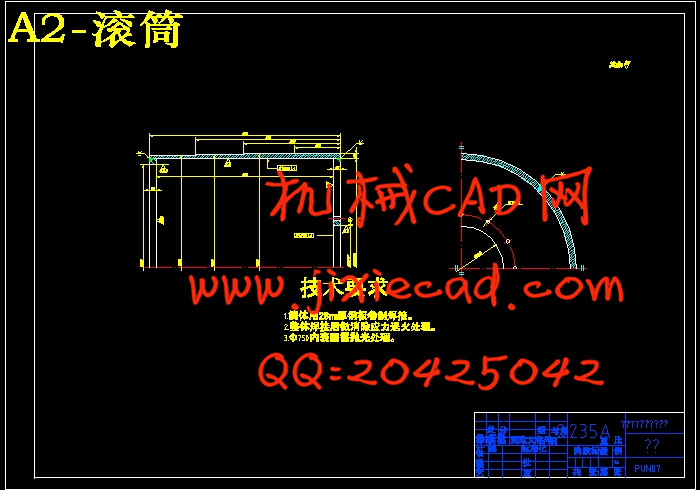

1 筒体、转盘质量及转动惯量计算……………………………………2

1.1筒体壁厚的计算…………………………………………………2

1.2筒体体积计算……………………………………………………3

1.3筒体质量计算……………………………………………………4

1.4筒体转动惯量计算………………………………………………5

1.5轴盘及转动惯量的计算…………………………………………5

2 电机的选择……………………………………………………………7

2.1类型………………………………………………………………7

2.2功率计算…………………………………………………………7

2.2.1启动转鼓等转动件所需功N1…………………………… 7

2.2.2 克服转鼓、物料与空气摩擦所需的功率N2………………7

2.3 选定……………………………………………………………8

2.4 工作原理………………………………………………………8

2.4.1 工作条件………………………………………………….8

2.4.2 负载特性…………………………………………………8

2.4.3 离心式分离机……………………………………………8

2.4.4 外形及安装尺寸Y90S-6………………………………….8

3 带轮的设计…………………………………………………………11

3.1 计算功率Pa……………………………………………………11

3.2 选择带轮型号…………………………………………………11

3.3 确定带轮的基准直径D1、D2……………………………………11

3.4 验算带轮V………………………………………………………11

3.5 确定中心距a和带的基准直径Ld…………………………….12

3.6验算小带轮上的包角α……………………………………….12

3.7 确定带的根数Z…………………………………………………12

3.8 计算轴压力Q……………………………………………………13

3.9 带轮材质………………………………………………………13

3.10 小带轮质量计算………………………………………………13

3.10.2 部分质量计算……………………………………………14

3.10.3 部分质量计算……………………………………………14

3.10.4 总质量∑m……………………………………………….14

3.11 大带轮质量计算………………………………………………15

3.11.1 部分质量计算………………………………………………15

3.11.2 部分质量计算………………………………………………15

3.11.3 总质量∑m…………………………………………………15

4轴的设计和校核………………………………………………………16

4.1 轴的设计计算…………………………………………………16

4.1.1 按弯扭合成强度计算轴径公式…………………………16

4.1.2 按扭转刚度计算轴径的公式……………………………16

4.1.3 取轴径……………………………………………………16

4.2 轴的结构设计…………………………………………………17

4.2.1 轴的强度计算…………………………………………….17

5 总质心的校核……………………………………………19

5.1 轴总质心的校核……………………………………………….19

5.1.1 轴质量计算………………………………………………19

5.1.2 轴质心校核……………………………………………….20

6 轴承的选择…………………………………………………………21

6.1 轴承的选择.设计及寿命校核……………………………….21

6.3 确定轴承寿命…………………………………………………21

6.2 当量动载荷……………………………………………………21

7 铆钉的计算…………………………………………………………22

7.1取半圆头铆钉…………………………………………………22

7.2.2 按扭转强度计算…………………………………………22

7.2.1 按铆钉剪切强度计算……………………………………22

7.2 确定铆钉的个数………………………………………………22

8 成型机的生产流程及电气控制……………………………………23

8.1 生产流程………………………………………………………23

8.2 电气控制原理…………………………………………………24

9 总结…………………………………………………………………26

10 参考文献……………………………………………………………27

11 致谢…………………………………………………………………28

12 附录…………………………………………………………………29

聚氨酯全称为聚氨基甲酸酯 ,是主链上含有重复氨基甲酸酯基团的大分子化合物的统称。它是由有机二异氰酸酯或多异氰酸酯与二羟基或多羟基化合物加聚而成。聚氨酯大分子中除了氨基甲酸酯外 ,还可含有醚、酯、脲、缩二脲 ,脲基甲酸酯等基团。

聚氨酯成型机是通过对聚氨酯加热到熔融状态,再靠离心机的离心原理将熔融的聚氨酯输送到搅拌头。经过高速强烈搅拌,使之料液均匀而喷出,形成所需产品。而离心成型技术是利用离心力成型管状或空心筒状制品的方法。通过挤出机或专用漏斗将定量的液态树脂或树脂分散体注入旋转并加热的容器(即模具)中,使其绕单轴高速旋转(每分钟几十转到两千转),此时放入的物料即被离心力迫使分布在模具的近壁部位。在旋转的同时,放入的物料发生固化,随后视需要经过冷却或后处理即能取得制品。在成型增强塑料制品时还可同时加入增强性的填料。离心浇铸通常用的都是熔体粘度较小、热稳定性较好的热塑性塑料,如聚酰胺、聚乙烯、聚氨酯等。

离心成型时,聚氨酯填充模具型腔主要靠的是离心机旋转时产生的离心力。离心力与质量成正比,与离心机转速的平方成正比,与旋转半径成正比。因此,对某一规格的转子而言,聚氨酯的质量和旋转半径是一定的,所以离心力的大小仅与离心机的转速有关,增大或减少离心力,只须改变离心机的转速即可。

在离心成型时,聚氨酯除了受到自身的重力作用外,主要是靠离心力的作用来填充模具型腔的,其填充方式是先填充远离旋转中心的型腔的外部,然后逐渐向心部填充完毕。因有离心力的存在,且它比重力大得多,所以聚氨酯的填充能力要比重力成型时强,只要离心机转速适当,离心力的大小合适,生产出的转子的质量就一定比浇注成型时形成的转子要好得多。

关键词:聚氨酯;离心成型;滚筒

Abstract

Polyurethane full-called polyurethane, is the main chain contains repeating urethane groups of molecules, collectively. It is an organic diisocyanate or polyisocyanate or polyol with two hydroxyl addition polymerization is made. Polyurethane macromolecules in addition to urethane, it can also contain ether, ester, urea, biuret, urea-based groups such as ester.

Polyurethane polyurethane molding machine is heated to melt through the state to rely on the principle of centrifuge centrifuge transported to the melting of the polyurethane mixing head. After strong stirring speed, so that even the spray liquid, to form the desired product. The centrifugal molding technology is the use of centrifugal force forming tubular or hollow tubular products method.Through the extruder hopper or dedicated to quantitative liquid resin or resin dispersion into the rotation and heating container (ie, mold), making it rotate around the axis high-speed (tens of per minute to two thousand rpm), then put incurs centrifugal force into the material distributed in the mold wall parts. Rotating at the same time, into the material cures, and then as needed through the cooling or post-processing that is able to obtain products. Enhanced the molding plastic products can also added to enhance the nature of filler. Centrifugal casting melt viscosity are usually smaller, better thermal stability of thermoplastics such as polyamide, polyethylene, polyurethane, etc.

Centrifugal molding, polyurethane fill the mold cavity is the main centrifuge rotation by the centrifugal force generated. Centrifugal force is proportional with the quality, speed proportional to the square with the centrifuge, and the radius is proportional to. Therefore, a specification of the rotor, the polyurethane is a certain quality and radius, so the size of the centrifugal force only with the speed of the centrifuge, increase or reduce the centrifugal force, centrifuge speed can only change.

In centrifugal molding, polyurethane except by their own gravity, the centrifugal force depends mainly on the role to fill the mold cavity, the fill mode is first filling away from the center of rotation of the external cavity, and then gradually to the heart of the Department of Tianchong completed . Due to the presence of centrifugal force, gravity force and it is much larger, so the polyurethane molding filling capacity than gravity is strong, as long as the appropriate centrifuge speed, the centrifugal force of the right size to produce the quality of the rotor must be better than pouring molding form The rotor is much better.

Key words: polyurethane; centrifugal molding; drum

目 录

引言………………………………………………………………………1

1 筒体、转盘质量及转动惯量计算……………………………………2

1.1筒体壁厚的计算…………………………………………………2

1.2筒体体积计算……………………………………………………3

1.3筒体质量计算……………………………………………………4

1.4筒体转动惯量计算………………………………………………5

1.5轴盘及转动惯量的计算…………………………………………5

2 电机的选择……………………………………………………………7

2.1类型………………………………………………………………7

2.2功率计算…………………………………………………………7

2.2.1启动转鼓等转动件所需功N1…………………………… 7

2.2.2 克服转鼓、物料与空气摩擦所需的功率N2………………7

2.3 选定……………………………………………………………8

2.4 工作原理………………………………………………………8

2.4.1 工作条件………………………………………………….8

2.4.2 负载特性…………………………………………………8

2.4.3 离心式分离机……………………………………………8

2.4.4 外形及安装尺寸Y90S-6………………………………….8

3 带轮的设计…………………………………………………………11

3.1 计算功率Pa……………………………………………………11

3.2 选择带轮型号…………………………………………………11

3.3 确定带轮的基准直径D1、D2……………………………………11

3.4 验算带轮V………………………………………………………11

3.5 确定中心距a和带的基准直径Ld…………………………….12

3.6验算小带轮上的包角α……………………………………….12

3.7 确定带的根数Z…………………………………………………12

3.8 计算轴压力Q……………………………………………………13

3.9 带轮材质………………………………………………………13

3.10 小带轮质量计算………………………………………………13

3.10.2 部分质量计算……………………………………………14

3.10.3 部分质量计算……………………………………………14

3.10.4 总质量∑m……………………………………………….14

3.11 大带轮质量计算………………………………………………15

3.11.1 部分质量计算………………………………………………15

3.11.2 部分质量计算………………………………………………15

3.11.3 总质量∑m…………………………………………………15

4轴的设计和校核………………………………………………………16

4.1 轴的设计计算…………………………………………………16

4.1.1 按弯扭合成强度计算轴径公式…………………………16

4.1.2 按扭转刚度计算轴径的公式……………………………16

4.1.3 取轴径……………………………………………………16

4.2 轴的结构设计…………………………………………………17

4.2.1 轴的强度计算…………………………………………….17

5 总质心的校核……………………………………………19

5.1 轴总质心的校核……………………………………………….19

5.1.1 轴质量计算………………………………………………19

5.1.2 轴质心校核……………………………………………….20

6 轴承的选择…………………………………………………………21

6.1 轴承的选择.设计及寿命校核……………………………….21

6.3 确定轴承寿命…………………………………………………21

6.2 当量动载荷……………………………………………………21

7 铆钉的计算…………………………………………………………22

7.1取半圆头铆钉…………………………………………………22

7.2.2 按扭转强度计算…………………………………………22

7.2.1 按铆钉剪切强度计算……………………………………22

7.2 确定铆钉的个数………………………………………………22

8 成型机的生产流程及电气控制……………………………………23

8.1 生产流程………………………………………………………23

8.2 电气控制原理…………………………………………………24

9 总结…………………………………………………………………26

10 参考文献……………………………………………………………27

11 致谢…………………………………………………………………28

12 附录…………………………………………………………………29