设计简介

摘要

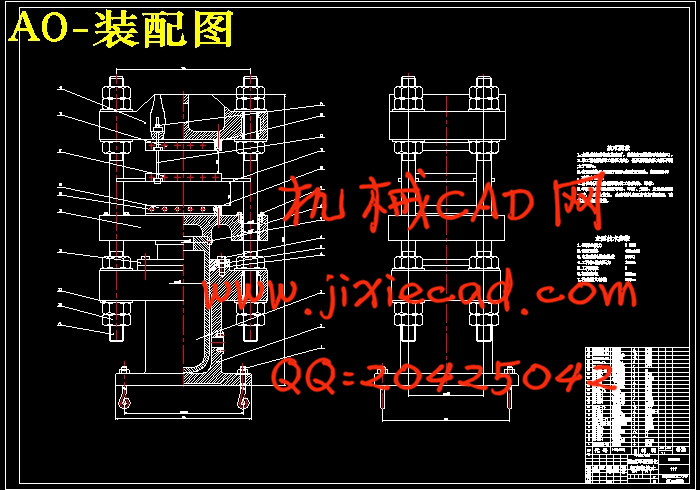

平板硫化机主要用于硫化平型胶带,属于液压机械,平板硫化机的主要功能是提供硫化所需的压力和温度。压力由液压系统通过液压缸产生,温度由加热介质蒸汽、导所提供。柱式平板硫化机全称为柱式液压传动平板硫化机,它的主要结构有底座、工作缸、柱塞、法兰、可动平台、加热板、上横梁和立柱等部件组成。

橡胶平板硫化机具有很多优点包括:1、设备操作可靠;2、维修量少;3,对各种优势的压力热板区,其主要功能是提供用于固化所需的温度和压力。它的主要用途就是硫化平型胶带。与我国传统常使用柱式结构与硫化机相比,具有巨大的优势。根据液压系统的工作介质可分为液压油的压力。根据工作层数分为单层和双层。它的工作原理是液压缸产生压力,加热介质提供温度。

有很多平板硫化机的类型,其范围也很宽,因此其分类可分为:

一、按用处差别可分为:橡胶模制品平板硫化机、 橡胶平带平板硫化机、橡胶V 带平板硫化机、橡胶板平板硫化机。

二、按传动体系可分为:液压式平板硫化机、机械式平板硫化机)、液压机械式平板硫化机。

三、按操纵系统可分为:非自动式平板硫化机、半自动式平板硫化机、自动式板硫化机。

四、按平板加热方法可分为:蒸汽加热平板硫化机、电加热平板硫化机——(在无热源或热源较远的场所使用。特点是温高、易控制、无泄漏,但成本高。实验平板硫化机用于实验室的平板硫化机加热模式。)过热水加热平板硫化机

五、按结构不同可分为:

1,根据框架结构分为:柱,框架式,侧板,连杆,旋转式平板硫化机

2、按加热平板的加热层数分为:单层式和多层式平板硫化机

3、按液压缸的数目分为:单液压缸和多液压缸式平板硫化机

4、根据液压缸的位置:上下缸式平板硫化机;立式、卧式平板硫化机。

连接方式为在工作缸内滑动,为了防止漏油在缸的上方放置两个密封圈,一个与法兰相接触,另一个与柱塞向接触,柱塞上部与可动平台链接,可动平台与下加热板之间有隔热板用螺钉固定,上横梁与上加热板也是中间有隔热板用螺栓固定,上横梁和底座之间用立柱和螺母固定,来确定整个平板硫化剂的稳定性。

它的基本工作原理是油泵通过管道进入缸内使柱塞拖动可动平台缓缓上升,直至上热板上升到对制品加压的作用,进行保压硫化,完成硫化作用缸内油由管道送出,使可动平台带动下热板放回。

我主要设计的是柱式平板硫化机的主要性能参数、主要零部件、传动系统和附属装置。使它们有机的结合在一起,构成完整的柱式平板硫化机。

关键词:柱式平板硫化机、液压传动、工作原理、连接方式。

Abstract

Plate vulcanizing machine is mainly used for vulcanizing flat tape, belong to the hydraulic machinery, plate vulcanizing machine's main function is to provide the necessary sulfide stress and temperature stress generated by the hydraulic system by hydraulic cylinder, the temperature of the steam by heating medium provided by the guide.

Column plate vulcanizing machine called the pillar type hydraulic drive plate vulcanizing machine, its main structure is the base working cylinder piston flange movable platform on the heating plate beam and column and other parts.

Rubber vulcanizing machine has many advantages including: 1, equipment operation and reliable; 2, small amount of maintenance; 3, the advantages of various pressure hot plate area, its main function is provided for the temperature and pressure required to cure. Its main purpose is to cure flat belt. With China's traditional commonly used column structure and vulcanizing machine, has a huge advantage. According to hydraulic system working medium can be divided into hydraulic oil pressure. According to the work layer, the layer is divided into single layer and double layer. Its working principle is hydraulic cylinder pressure, heating medium provides temperature.

There are many types of flat curing machines, its range is also very wide, so its classification can be divided into:

A, according to the use of differences can be divided into: rubber mold plate curing machine, rubber flat with flat vulcanized rubber, rubber V with flat plate curing machine, rubber plate plate curing machine.

Two, according to the transmission system can be divided into: hydraulic type flat plate curing machine, mechanical flat type curing machine, hydraulic mechanical type plate curing machine.

Three, according to the operating system can be divided into: non automatic flat plate curing machine, semi-automatic flat plate curing machine, automatic type plate curing machine.

Four, according to the plate heating method can be divided into: steam heating flat plate curing machine, electric heating flat curing machine - (in no heat source or heat source far place use. Features are high temperature, easy control, no leakage, but high cost. The experimental plate curing machine is used for the heating mode of the flat curing machine in the laboratory. Hot plate curing machine with hot water

Five, according to the structure can be divided into different:

1, according to the frame structure is divided into: column, frame, plate, rod, rotary type plate vulcanizing machine

2, according to the heating layer of heating layer is divided into: single type and multi-layer plate curing machine

3, according to the number of hydraulic cylinders: single hydraulic cylinder and multi hydraulic cylinder type plate curing machine

4, according to the position of hydraulic cylinder: upper and lower cylinder type plate curing machine; vertical, horizontal plate curing machine.

Connection mode for sliding in cylinder in work, in order to prevent oil spill two seals are placed in the top of the cylinder, a contact with the flange, the other one with the plunger to the contact, column inserting and movable platform links, movable platform and the insulation between the heating plate, with screws on the beam and on the heating plate is bolted with heat insulation board, between the beam and the base with stud and nut, to determine the stability of the whole plate vulcanizing agent.

It is the basic working principle of oil pump into the cylinder pull the plunger moving platform slowly rise, until the hot plate to the products on the effect of pressure, pressure maintaining sulfide, complete vulcanization in cylinder oil by pipeline is sent out, the movable platform driven back into the hot plate.

I mainly design of column type plate vulcanizing machine is the main performance parameters of main transmission system parts and accessory device Make them organic unifies in together, form a complete column type plate vulcanizing machine.

Key words: Column plate vulcanizing machine; Hydraulic drive; Principle of work; Connection mode.

目 录

第一章 概述 1

1.1 平板硫化机的分类与用途 1

1.1.1 用途 1

1.1.2 分类 1

1.2 平板硫化机的作用 2

1.3 平板硫化机的工作原理和规格与技术特征 2

1.3.1 工作原理 2

1.3.2 规格与技术特征 2

第二章 平板硫化机的主要技术参数的确定 3

第三章 主要零部件的基础结构设计 4

3.1 柱塞的设计 4

3.1.1 柱塞的结构及材料 4

3.1.2柱塞外径的确定 4

3.1.3柱塞壁厚的确定 5

3.1.4柱塞内径及其它尺 6

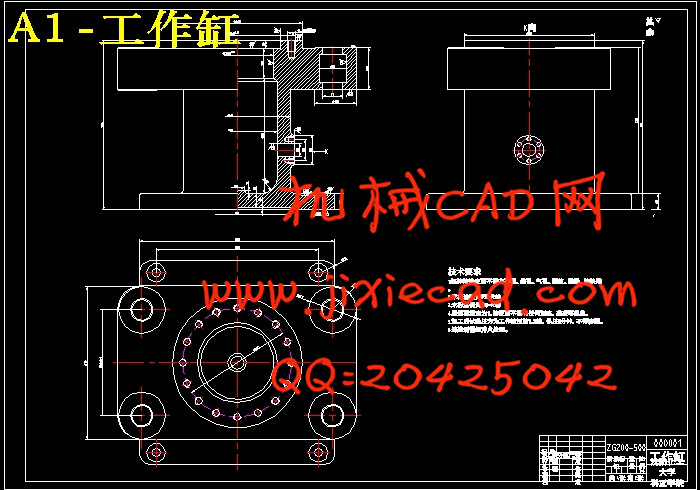

3.2工作缸的设计 6

3.2.1 工作缸的结构及材料 6

3.2.2 工作缸的结构尺寸 7

3.2.3 工作缸的其他部分尺寸的确定 7

3.2.4 工作缸强度校合 9

3.3 密封装置 10

3.3.1 密封件 10

3.3.2 法兰尺寸及法兰螺栓的选择 11

3.4 立柱与螺母 12

3.4.1 立柱的选材及尺寸的确定 13

3.4.2 螺母的选材及尺寸 14

3.5 上横梁 15

3.5.1 上横梁的结构及材料 15

3.5.2 弯矩及弯曲应力的校核 15

3.5.3 上横梁的最大挠度 17

3.6 热板 18

3.6.1 热板的结构及材料的选择 18

3.6.2 热版内电加热元件的选择 18

3.7 可动平台 19

3.7.1 可动平台的结构及选择 19

3.7.2 平台受载荷及弯矩情况 19

3.7.3 可动平台挠度的计算 21

3.7.4 可动平台的校核 21

3.8 底座 23

3.8.1 底座的结构和材料 24

3.8.2 底座的强度校核 24

结 论 27

参考文献 28

致 谢 29