设计简介

摘 要

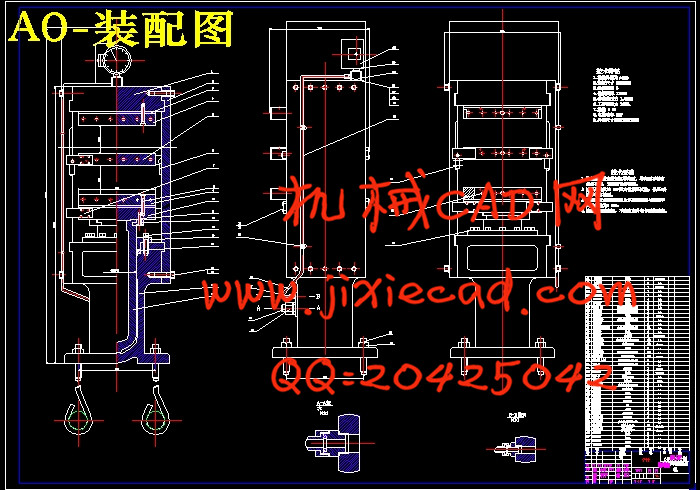

本次设计设计的是QLB-600×600侧板式平板硫化机,介绍了平板硫化机的发展史,并对QLB-600×600侧板式平板硫化机的零部件进行了设计计算和校核。平板硫化机作为一种硫化设备,有柱塞、工作缸、密封装置、法兰等组成的 传递液压能的部件将液体的压力转变成带动平台运动的动能以及供应品硫化时 所需要的压力能。利用安置在热板中的加热设备与机械部分配合使用,加热、加 压一定时间,就可满足制品硫化的三要素:时间、压力、温度。

侧板式平板硫化机的工作原理是,柱塞通过液压力带动可动平台上升,使被 固定在平台上的热板一起上升,并与上层热板夹住制品,在一定时间的硫化作用 下,形成成品。

由于模型橡胶制品、输送带、胶板及合成塑料的应用不断的发展,促进了平板硫化机的发展,同时也对平板硫化机的性能提出了更高的要求。

关键字:平板硫化机、侧板、硫化设备

Abstract

This design desing is OLB-D150 /the600*600 side bar typep plate vulcanizing machine,introduced the plate vulcanizing machine history,and side bar type plate vulcanizing machine spare part has carried on the desing calculation to OLB-D150 /the600*600 and corrects.The plate vulcanizing machine took one kind of curing equipment,by the plunger,the woork cylinder,the packing assembly,the flange and so on the rtansmission hydraulic pressure which is composed can the pressure energy which the part transforms the liquid pressure leads the platfrm movement the kinetic energy as well as for product curing when needs.Using places in the hot plate the heater and the machine part cordination use,the heating,compression certion time maysatisfy the product curing three essential factor:Time,pressrue,temperatrue.

The side bar type plate vulcanizing machine principle of work is ,the plunger through the hydraulic pressure inpetus movable platform rise,causes to fix the bot plate rises together in the platform,and grips the produvt with the upper formation hot plate,in under certain time sulfurization,forms the end product.

Because model rubber product,conveyor belt,off-set and synthesis plastic application unceasing development,promoted,the plate vulcanizing machine development,simultaneously also set a higher request to the plate vulcanizing macineperformance.

Key words: Plate vulcanizing machine, The side bar type plate, Curing epuipment, Curing equipment,curing equipment

目 录

摘要 1

Abstract 2

第一章 前言 1

第二章 主要零部件的设计及校核 1

2.1柱塞 1

2.1.1柱塞的选材 1

2.1.2柱塞外径D2 1

2.1.3柱塞内径D1 2

2.1.4柱塞与平台的连接方式 2

2.2工作缸 3

2.2.1工作缸选材 3

2.2.2工作缸内腔直径 3

2.2.3工作缸壁厚 3

2.2.4工作缸外径 4

2.2.5工作缸强度校核 5

2.3密封装置 6

2.3.1密封件 6

2.3.2法兰 7

2.4热板 10

2.5可动平台 11

2.5.1可动平台的选材 11

2.5.2平台受载荷及弯矩 11

2.5.3可动平台弯矩 12

2.5.4强度校核 12

2.6侧板 14

2.7上横梁 18

2.7.1选材 18

2.7.2上横梁的结构及强度校核 18

结论 1

致谢 1

参考文献 1