设计简介

摘 要:玉米作为我国第二大农作物,与之相对应的我国玉米收割机发展比较迟滞。本文的出发点正鉴于此,着重分析玉米收获机的摘穗机构,玉米收获机摘穗机是整个玉米收获机械的核心部件,它最大程度地决定了玉米成熟期机械收获作业质量。

本文对玉米收割机摘穗机构进行了整体的机构理论研究。分析国内外的各种型号玉米收割机的不同摘穗方式,选择一种合理使用的摘穗方式,并对其中的关键部位进行了设计计算,主要包括拉茎辊、摘穗板和传动机构的设计,保证了机构运行的可靠性。

关键词:拉茎辊;摘穗板;传动机构;收获机

Abstract:Corn as the second largest crop in our country, compared with the corresponding development of China's corn harvester of hysteresis. The starting point of this article is in view of this, focusing on the analysis of corn harvester pick guangzhou agency, corn harvester picker is the core parts of the corn harvest machine, it will determine the maximum mechanical harvesting operation quality corn ripening stage.

In this paper, ear of corn harvester picking mechanism has carried on the overall organization theory research. Analysis of various models at home and abroad different picking ears of corn harvester, choose a reasonable use way of picking ears, and the key parts for the design and calculation, mainly including stem roller, pick the ear plate and the transmission mechanism design, ensure the reliability of the operation.

Key words: Pull stem roll;Pick the ear plate;Transmission mechanism;harvester

目 录

摘要……………………………………………………………………………1

关键词……………………………………………………………………………1

1前言……………………………………………………………………………2

1.1课题的目的………………………………………………………………………2

1.2国内外动态………………………………………………………………………2

1.2.1国外的发动态…………………………………………………………………2

1.2.2国内的发展动态………………………………………………………………2

1.3玉米收获机摘穗形式分类………………………………………………………3

1.3.1立式摘穗辊型玉米收获机……………………………………………………3

1.3.2卧式摘穗辊型玉米收获机……………………………………………………3

1.3.3摘穗板型玉米收获机…………………………………………………………4

2 研究的主要内容……………………………………………………………………4

2.1摘穗机构设计……………………………………………………………………4

2.2.1 摘穗形式的确定………………………………………………………………4

2.1.2总体方案的拟定………………………………………………………………4

3主要工作部件的设计………………………………………………………………5

3.1拉茎辊的结构设计………………………………………………………………5

3.1.1拉茎辊的直径设计……………………………………………………………7

3.1.2拉茎辊的转速、间隙、长度的确定…………………………………………8

3.1.3螺旋筋的设计…………………………………………………………………8

3.2摘穗板的结构设计………………………………………………………………8

3.3拉茎辊、摘穗板具体设计方案…………………………………………………8

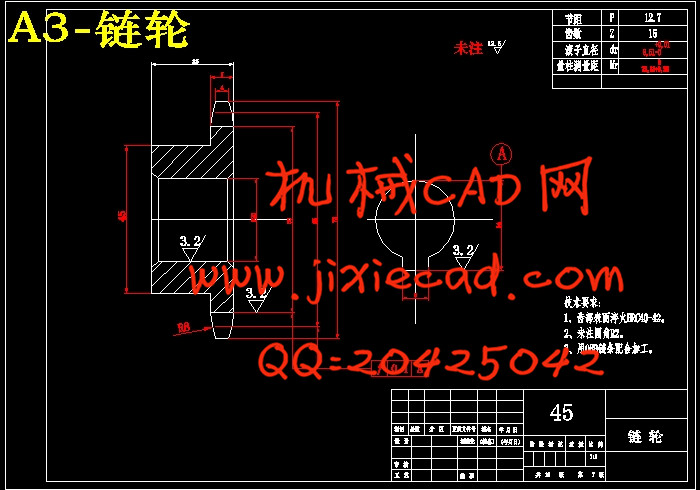

4传动方案的确定及设计计算………………………………………………………9

4.1摘穗传动箱的设计………………………………………………………………9

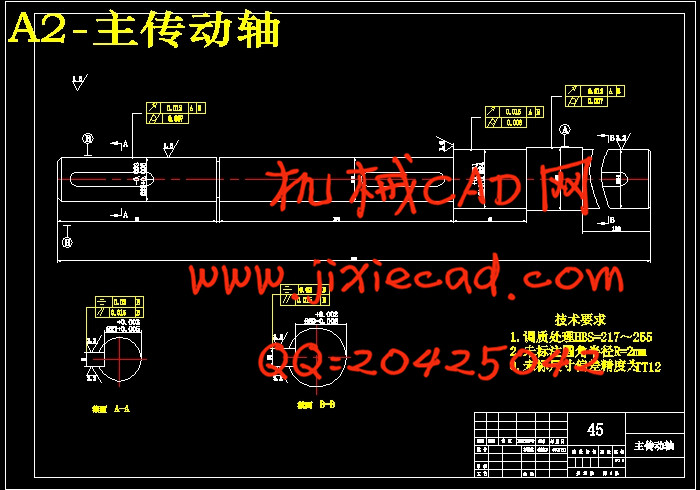

4.2轴的校核…………………………………………………………………………12

4.2.1按扭矩初步确定轴径…………………………………………………………13

4.2.2轴的结构设计…………………………………………………………………13

4.2. 3轴的强度校核…………………………………………………………………15

4.3滚动轴承的设计计算……………………………………………………………16

4.3.1轴承载荷校核…………………………………………………………………17

4.3.2轴承寿命校核…………………………………………………………………17

4.4平键的选择与计算………………………………………………………………17

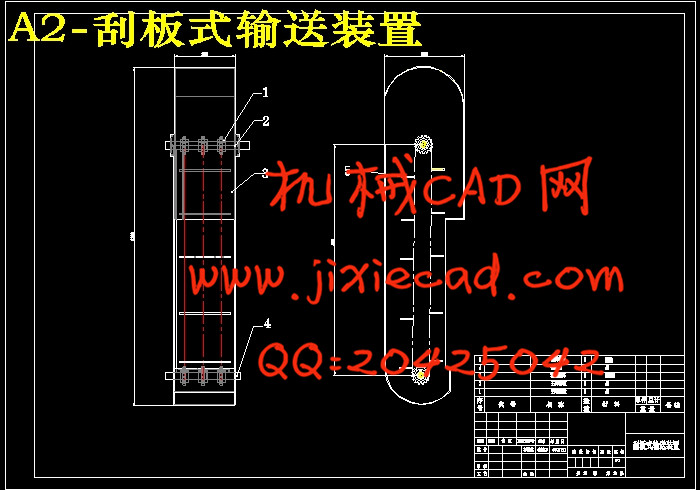

4.5刮板式输送装置的设计…………………………………………………………18

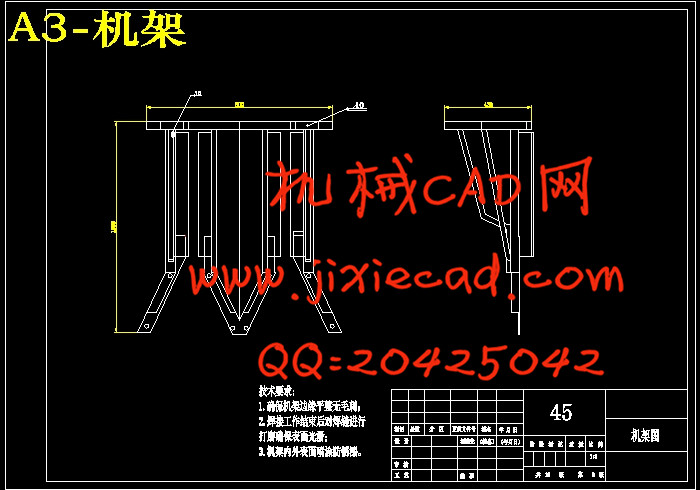

4.6机架的结构设计…………………………………………………………19

5总结…………………………………………………………………………………20

参考文献………………………………………………………………………………20

致谢…………………………………………………………………………………21

本文对玉米收割机摘穗机构进行了整体的机构理论研究。分析国内外的各种型号玉米收割机的不同摘穗方式,选择一种合理使用的摘穗方式,并对其中的关键部位进行了设计计算,主要包括拉茎辊、摘穗板和传动机构的设计,保证了机构运行的可靠性。

关键词:拉茎辊;摘穗板;传动机构;收获机

Abstract:Corn as the second largest crop in our country, compared with the corresponding development of China's corn harvester of hysteresis. The starting point of this article is in view of this, focusing on the analysis of corn harvester pick guangzhou agency, corn harvester picker is the core parts of the corn harvest machine, it will determine the maximum mechanical harvesting operation quality corn ripening stage.

In this paper, ear of corn harvester picking mechanism has carried on the overall organization theory research. Analysis of various models at home and abroad different picking ears of corn harvester, choose a reasonable use way of picking ears, and the key parts for the design and calculation, mainly including stem roller, pick the ear plate and the transmission mechanism design, ensure the reliability of the operation.

Key words: Pull stem roll;Pick the ear plate;Transmission mechanism;harvester

目 录

摘要……………………………………………………………………………1

关键词……………………………………………………………………………1

1前言……………………………………………………………………………2

1.1课题的目的………………………………………………………………………2

1.2国内外动态………………………………………………………………………2

1.2.1国外的发动态…………………………………………………………………2

1.2.2国内的发展动态………………………………………………………………2

1.3玉米收获机摘穗形式分类………………………………………………………3

1.3.1立式摘穗辊型玉米收获机……………………………………………………3

1.3.2卧式摘穗辊型玉米收获机……………………………………………………3

1.3.3摘穗板型玉米收获机…………………………………………………………4

2 研究的主要内容……………………………………………………………………4

2.1摘穗机构设计……………………………………………………………………4

2.2.1 摘穗形式的确定………………………………………………………………4

2.1.2总体方案的拟定………………………………………………………………4

3主要工作部件的设计………………………………………………………………5

3.1拉茎辊的结构设计………………………………………………………………5

3.1.1拉茎辊的直径设计……………………………………………………………7

3.1.2拉茎辊的转速、间隙、长度的确定…………………………………………8

3.1.3螺旋筋的设计…………………………………………………………………8

3.2摘穗板的结构设计………………………………………………………………8

3.3拉茎辊、摘穗板具体设计方案…………………………………………………8

4传动方案的确定及设计计算………………………………………………………9

4.1摘穗传动箱的设计………………………………………………………………9

4.2轴的校核…………………………………………………………………………12

4.2.1按扭矩初步确定轴径…………………………………………………………13

4.2.2轴的结构设计…………………………………………………………………13

4.2. 3轴的强度校核…………………………………………………………………15

4.3滚动轴承的设计计算……………………………………………………………16

4.3.1轴承载荷校核…………………………………………………………………17

4.3.2轴承寿命校核…………………………………………………………………17

4.4平键的选择与计算………………………………………………………………17

4.5刮板式输送装置的设计…………………………………………………………18

4.6机架的结构设计…………………………………………………………19

5总结…………………………………………………………………………………20

参考文献………………………………………………………………………………20

致谢…………………………………………………………………………………21