设计简介

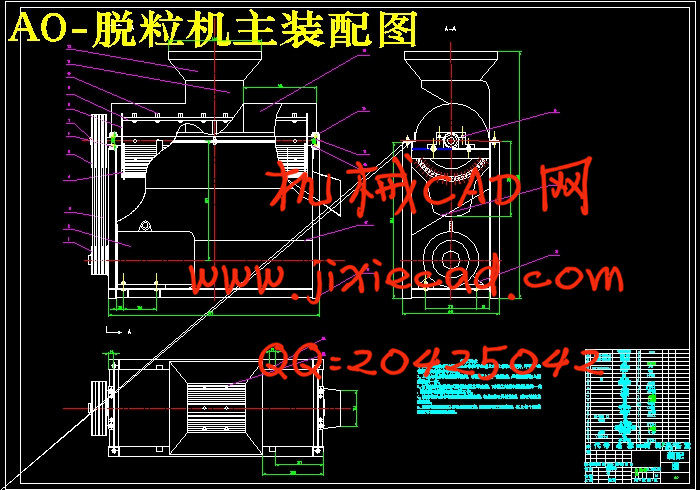

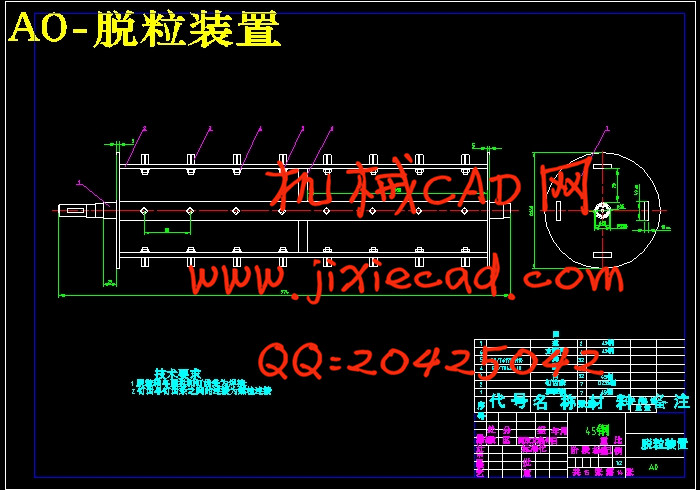

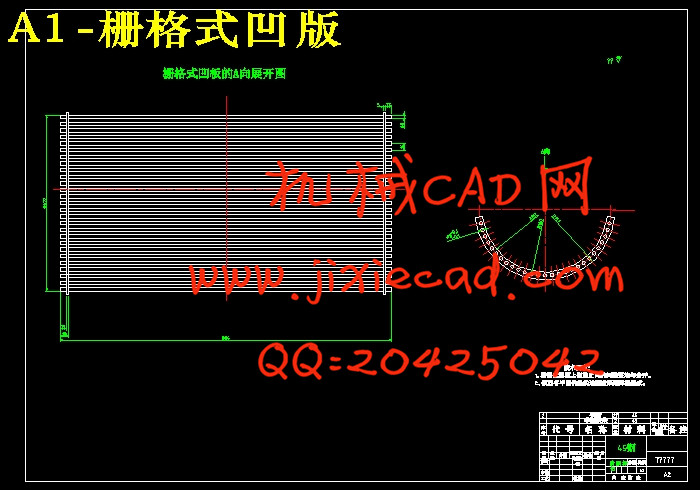

摘 要:为了减少农民在脱去玉米粒的时候时的劳动强度、提高其农业生产效率,所以设计玉米脱粒机。该机主要有入料口、栅格式凹板和钉齿脱粒滚筒及传动部件等组成。以电动机为动力源,动力由电动机输出轴输出,再通过传动带传递到钉齿脱粒滚筒上,钉齿脱粒滚筒配合栅格式凹板将玉米脱粒,玉米粒从栅格式凹板分离并排出机体外,而玉米芯从入料的另一端排出机体之外。其工艺流程:玉米穗通过入料斗进料口进入钉齿滚筒,在高速回转钉齿滚筒的冲击和玉米穗、钉齿滚筒,栅格式凹版的相互作用下被脱粒。脱下的籽粒通过栅格式凹版由出粒板滑出机体,而玉米芯则随着螺旋排列的钉齿由出芯口排出机体。为了保证有玉米穗顺利的喂入而不堵塞滚筒,进料口下底板应该有一定的斜度,玉米芯排出口应与籽粒排出口保持一定的距离,以免玉米芯与籽粒相混杂。玉米脱粒机的生产效率决定于配套动力的大小。其功率消耗可按1kw.h的功可脱600~1000kg已拨皮的玉米穗计算。未剥皮的玉米穗直接进行脱粒时,其生产率约为30%~50%。

关键词:脱粒机,入料装置,脱粒装置

Abstract: In oder to reducing a peasant during the period of the maize threshes, the intensity of labour, raises working efficiency , designs Corn threshing machine. Be machine's turn to have mainly enter expect that the mouth , bars form notch board and nail tooth the cylinder threshing and drive component etc. are composed of. Take electric motor as driving force source, driving force exports axis output from the electric motor , the nail tooth seed-husking cylinder threshes on the cylinder threshing again by the fact that belt delivery arrives at the nail tooth, coordinating bars form notch board with the corns, besides seeds complies with bars form notch board separation and the outside discharging airframe, but the maize core discharges airframe from another one end entering material.Its process flow :The corn ears though hopper entering the threshing device, under the high speed rolling cylinder which installed the nails crash and the corn ears squeeze with the notch board, the seed will be drained. Than drained seeds will through the board slipped outside. Cob drained outside under the spiral nails help.In oder to make corn ears fluently entering the body ,and can not clog th the body ,the steel board of the bottom of hopper, should be designed set a angle .The corncob escapement should maintain certain distance with the grain escapement, in order to avoid the corncob and the grain are mixed.Corn threshing's production efficiency decides in the necessary power size. Its power dissipation may be possible to escape 600~1000kg according to the 1kw.h merit to dial the corn skin computation. That has not skinned when directly the corn carries on the seed extraction, its productivity approximately is 30%~50%.

Key words: Threshing machine,Enter device, Thresher device

目 录

摘要…………………………………………………………………………………1

关键词 ……………………………………………………………………………………1

1 前言…………………………………………………………………………………2

2 总体方案拟定………………………………………………………………………2

2.1 工作原理分析…………………………………………………………………… 3

2.2 方案与技术设计…………………………………………………………………3

3 玉米脱粒机的设计计算…………………………………………………………4

3.1 电动机的选择……………………………………………………………………4

3.2 脱粒轴的设计……………………………………………………………………6

3.2.1 最小脱粒轴直径………………………………………………………… 6

3.2.2 脱粒轴的基本结构………………………………………………………7

3.2.3 轴的校核………………………………………………………………… 8

3.3 钉齿条的总体结构设计 ……………………………………………………… 11

3.3.1 钉齿条的功用…………………………………………………………11

3.3.2 钉齿条的结构及选材…………………………………………………12

3.4 钉齿的设计 …………………………………………………………………… 13

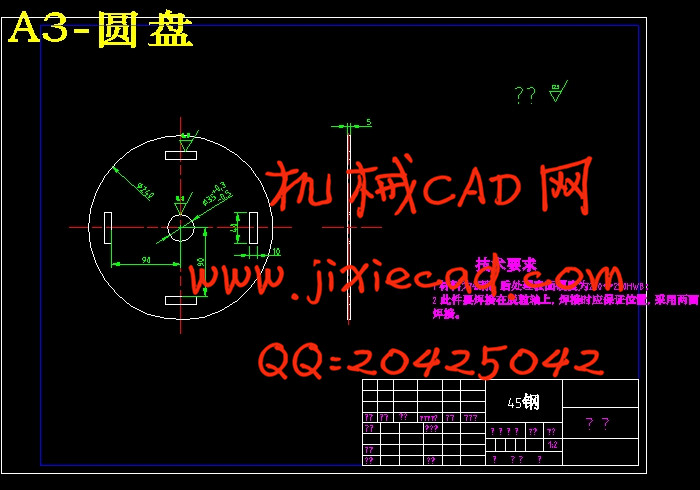

3.5 圆盘的设计…………………………………………………………………13

3.5.1 圆盘的特点……………………………………………………………13

3.5.2 圆盘的结构及材料……………………………………………………14

3.6 栅格式凹版的设计 …………………………………………………………… 14

3.6.1 栅格式凹版的功能…………………………………………………14

3.6.2 栅格式凹版的选用…………………………………………………15

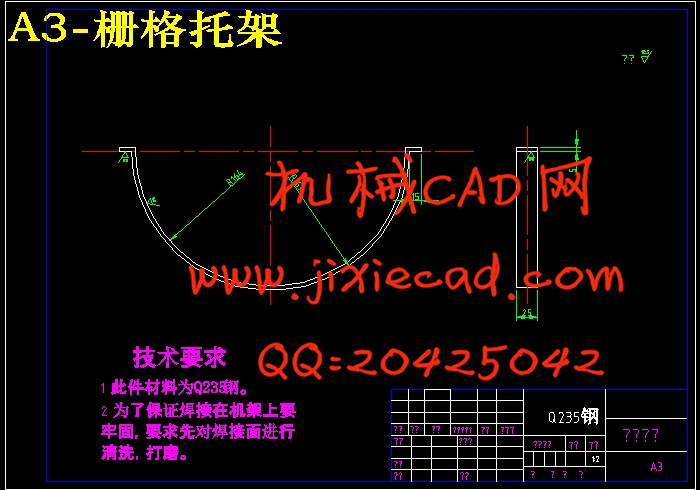

3.7 栅格托架的选用 ……………………………………………………………… 16

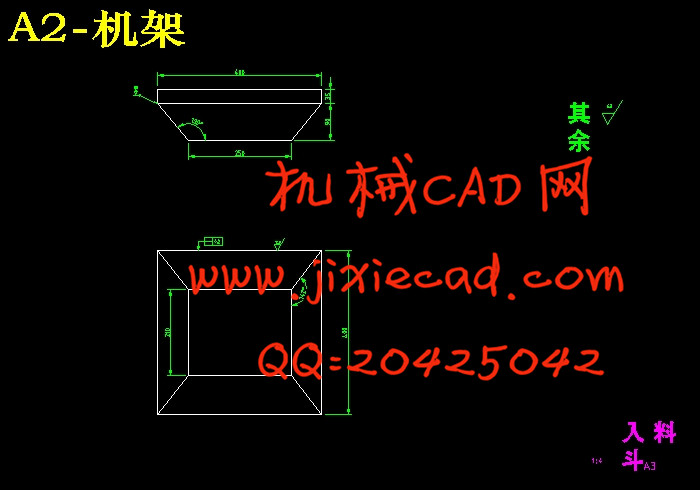

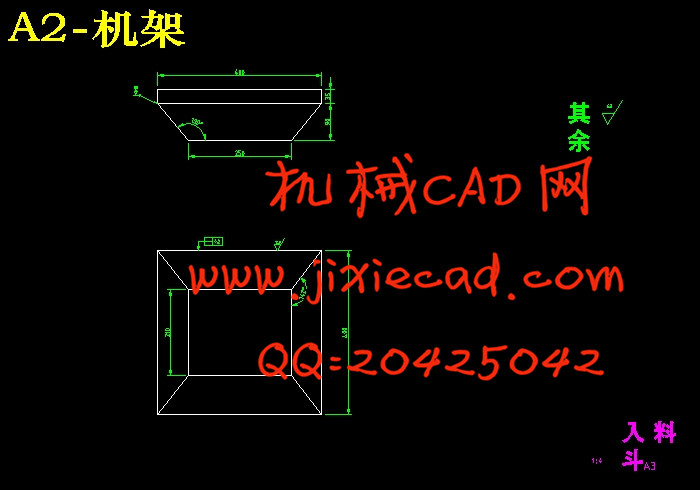

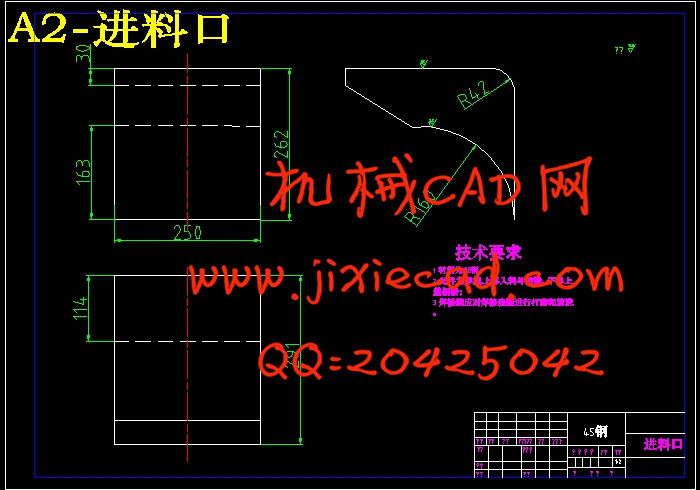

3.8 入料斗和进料口的设计………………………………………………………16

3.8.1 入料斗和进料口的选择………………………………………………16

3.8.2 入料斗和进料口的结构………………………………………………17

3.9 上盖的设计 …………………………………………………………………… 18

3.10 键的选择与校核……………………………………………………………… 19

3.10.1 轴上键的选择………………………………………………………… 19

3.10.2 键的校核……………………………………………………………… 19

3.11 轴承的选择和校核…………………………………………………………… 19

3.11.1 轴承的型号…………………………………………………………… 19

3.11.2 轴承的校核……………………………………………………………20

3.12 玉米脱粒机上盖螺栓的选择………………………………………………… 20

3.12.1 螺栓的强度校核………………………………………………………20

3.12.2 螺栓的型号选择………………………………………………………21

4 结论……………………………………………………………………………………21

参考文献…………………………………………………………………………………22

致谢……………………………………………………………………………………23