设计简介

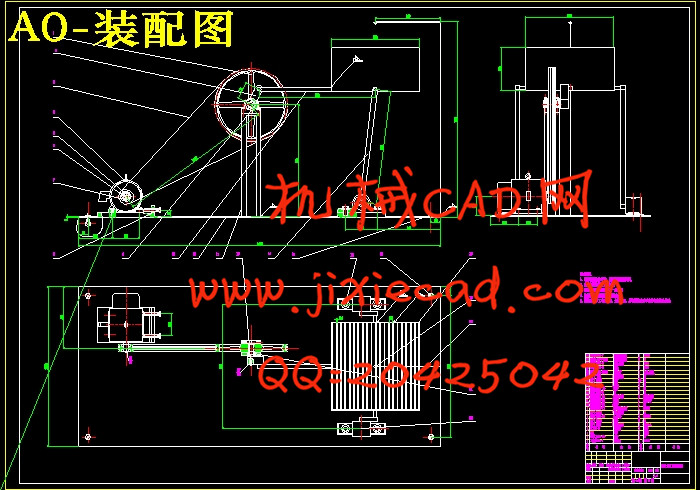

摘 要:振动式红薯清洗机的基本工作原理是利用筛箱的振动,使红薯在其中不断地碰撞和摩擦,同时用高压水冲洗,以达到去泥沙和清洗的效果。本文包括原动部分,传动部分,执行部分以及各零部件的设计计算。本设计的主要特点是:结构简单,节省投资,工作高效,能很好地实现红薯清洗的机械化。

关键词:传动系统;连杆机构;振动;喷淋

Abstract: In order to achieve to sediment and cleaning effect,basic working principle of vibrating sweet potato washing machine is the use of the vibration of the sieve box, making sweet potato in constant collision and friction, rinsing with high pressure water at the same time.In this paper, including the original part, transmission part, execute part and the design and calculation of components. The design of the main features are: simple structure, saving investment, working efficient, it can well realize sweet potato mechanization cleaning.

Key word: The transmission system; Linkage; Vibration;Spray

目 录

摘要…………………………………………………………………………………1

关键词………………………………………………………………………………1

1 前言………………………………………………………………………………1

2 方案比较…………………………………………………………………………2

3 执行机构…………………………………………………………………………3

3.1 连杆机构的特点………………………………………………………………3

3.2 连杆机构的选择………………………………………………………………4

3.3 平面四杆机构有曲柄的条件…………………………………………………5

3.4 无急回特性杆长的设计………………………………………………………5

3.5 校核最小传动角………………………………………………………………6

3.6 杆件的设计……………………………………………………………………6

3.6.1 杆件材料的选择……………………………………………………………6

3.6.2 杆件截面直径的确定………………………………………………………6

3.6.3 稳定性校核…………………………………………………………………8

4 原动部分…………………………………………………………………………8

5 传动部分…………………………………………………………………………10

5.1 传动方案对比…………………………………………………………………10

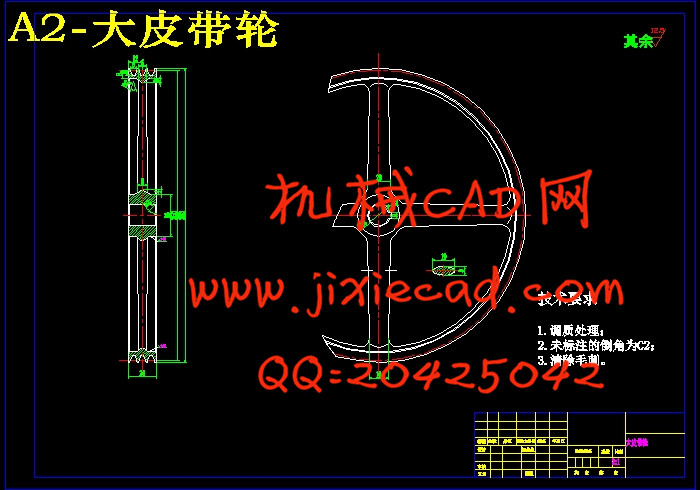

5.2 V带传动的设计计算…………………………………………………………10

5.3 V带轮的设计…………………………………………………………………11

5.4 V带传动的张紧………………………………………………………………12

6 零部件的结构和尺寸的确定……………………………………………………13

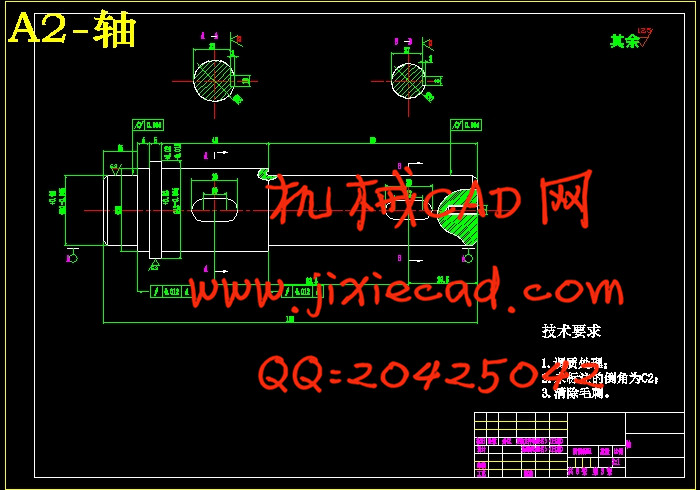

6.1 大带轮轴的设计………………………………………………………………13

6.1.1 轴的强度校核计算…………………………………………………………13

6.1.2 拟定轴上零件的装配方案…………………………………………………14

6.1.3 根据轴向定位确定轴的各段直径和长度…………………………………15

6.2 轴的校核………………………………………………………………………15

6.3 轴承的校核……………………………………………………………………17

6.4 键的选择和校核………………………………………………………………17

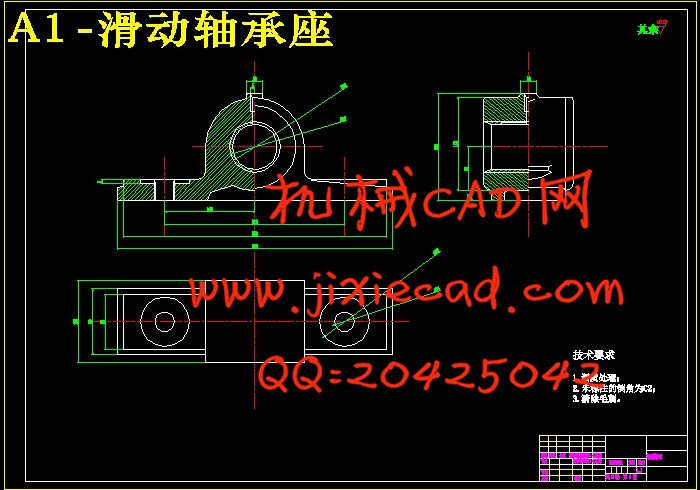

6.5 滑动轴承………………………………………………………………………18

6.6 轴端挡圈………………………………………………………………………18

6.7 支架稳定性校核…………………………………………………………………19

7 振动清洗箱………………………………………………………………………19

8 箱体机架的确定…………………………………………………………………19

9 清洗喷头…………………………………………………………………………20

10 出水槽…………………………………………………………………………20

11 润滑……………………………………………………………………………20

12 结论……………………………………………………………………………20

参考文献……………………………………………………………………………21

致谢…………………………………………………………………………………22

关键词:传动系统;连杆机构;振动;喷淋

Abstract: In order to achieve to sediment and cleaning effect,basic working principle of vibrating sweet potato washing machine is the use of the vibration of the sieve box, making sweet potato in constant collision and friction, rinsing with high pressure water at the same time.In this paper, including the original part, transmission part, execute part and the design and calculation of components. The design of the main features are: simple structure, saving investment, working efficient, it can well realize sweet potato mechanization cleaning.

Key word: The transmission system; Linkage; Vibration;Spray

目 录

摘要…………………………………………………………………………………1

关键词………………………………………………………………………………1

1 前言………………………………………………………………………………1

2 方案比较…………………………………………………………………………2

3 执行机构…………………………………………………………………………3

3.1 连杆机构的特点………………………………………………………………3

3.2 连杆机构的选择………………………………………………………………4

3.3 平面四杆机构有曲柄的条件…………………………………………………5

3.4 无急回特性杆长的设计………………………………………………………5

3.5 校核最小传动角………………………………………………………………6

3.6 杆件的设计……………………………………………………………………6

3.6.1 杆件材料的选择……………………………………………………………6

3.6.2 杆件截面直径的确定………………………………………………………6

3.6.3 稳定性校核…………………………………………………………………8

4 原动部分…………………………………………………………………………8

5 传动部分…………………………………………………………………………10

5.1 传动方案对比…………………………………………………………………10

5.2 V带传动的设计计算…………………………………………………………10

5.3 V带轮的设计…………………………………………………………………11

5.4 V带传动的张紧………………………………………………………………12

6 零部件的结构和尺寸的确定……………………………………………………13

6.1 大带轮轴的设计………………………………………………………………13

6.1.1 轴的强度校核计算…………………………………………………………13

6.1.2 拟定轴上零件的装配方案…………………………………………………14

6.1.3 根据轴向定位确定轴的各段直径和长度…………………………………15

6.2 轴的校核………………………………………………………………………15

6.3 轴承的校核……………………………………………………………………17

6.4 键的选择和校核………………………………………………………………17

6.5 滑动轴承………………………………………………………………………18

6.6 轴端挡圈………………………………………………………………………18

6.7 支架稳定性校核…………………………………………………………………19

7 振动清洗箱………………………………………………………………………19

8 箱体机架的确定…………………………………………………………………19

9 清洗喷头…………………………………………………………………………20

10 出水槽…………………………………………………………………………20

11 润滑……………………………………………………………………………20

12 结论……………………………………………………………………………20

参考文献……………………………………………………………………………21

致谢…………………………………………………………………………………22