设计简介

小功率机械无级变速器结构设计

摘要:机械无级变速器是一种能适应工艺要求多变、工艺流程机械化和自动化发展以及改善机械工作性能的一种通用传动装置。本文简要介绍了摩擦式机械无级变速器的基本结构、设计计算的方法、材质及润滑等方面的知识,并以此作为本次无级变速器设计的理论基础。

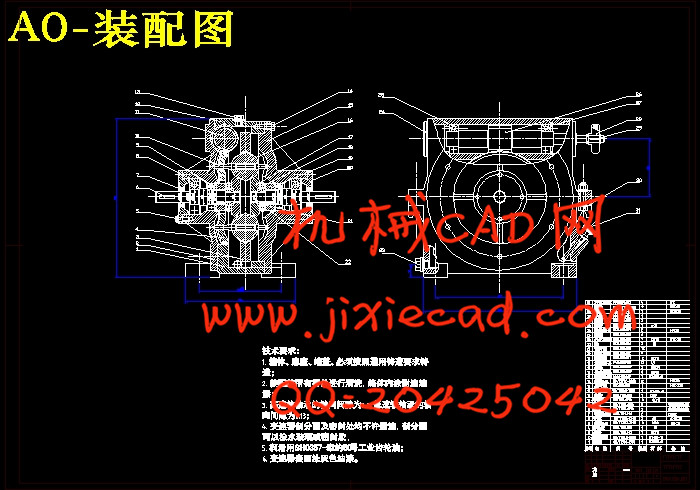

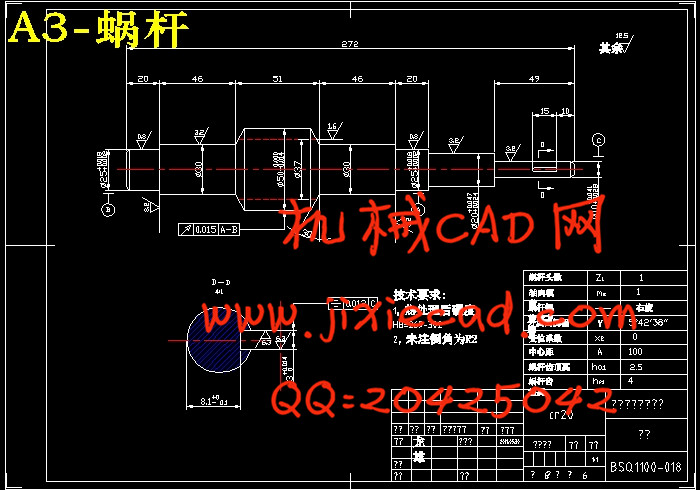

本设计采用的是以钢球锥轮作为中间传动元件,通过改变钢球的工作半径来实现输出轴转速连续变化的钢球锥轮式无级变速器。本文分析了在传动过程中变速器的主、从动轮,钢球和外环的工作原理和受力关系;详细推导了实用的钢球锥轮式无级变速器设计的计算公式;并针对设计所选择的参数进行了具体的设计计算;绘制了所计算的钢球锥轮式无级变速器的装配图和主要传动元件的零件图,将此变速器的结构和工艺等方面的要求表达得更为清楚。

这种无级变速器有良好的结构和性能优势,具有很强的实用价值,完全可以作为批量生产的无级变速器。其主要特点是:1.变速范围较宽;2.恒功率特性好;3.可以升、降速,正、反转。4.运转平稳,抗冲击能力较强;5.输出功率较大;6.使用寿命长;7.调速简单,工作可靠;8.容易维修。

关键词:无级变速器,摩擦式,钢球锥轮式,设计。

Small power machinery variator structure design

Abstract: The mechanical variable speed drives is a general purpose gearing which can accommodate the variable requirements of the process planning, mechanization of the schedule drawing ,the development of automation and the improvement of the mechanical working capabilities. The article briefly introduce the basic structure, the way of design and calculation, material and lubricate of the frication type variable speed drives, and taking them as the theory basis of the design of mechanical variable speed drives.

This design uses the ball pyramid wheel as the middle transmission component, by changing its’ working radius to realize the continuous change of the output axis. This article analyzes the working theory and the working forces of the drive wheel, ball wheel and outer ring during the transmission process. It also deduces the practical calculation formula of the ball pyramid wheel type variable speed drives, it also goes on the material calculation aim at the selection parameter. It protracts the assemble-drawing of the ball pyramid wheel type variable speed drives and the accessory-drawing of the mostly drive component. So it can express more clearly of the structure and process planning of the variable speed drives.

The variable speed drives has good structure and properties, and it can use as batch production. The most specialties: 1 wide range of variable speed;2 the constant output power;3 it can rotate positively and versedly;4 stable accuracy of speed;5 high output power;6 long life;7 simply and precise control of speed;8 easy maintain.

Keywords: CVT,friction type,ball pyramid type,design.

目 录

摘要 ………………………………………………………………………………………Ⅱ

Abstract……………………………………………………………………………………Ⅲ

第一章 绪论 ………………………………………………………………………………1

1.1 机械无级变速器的发展概况 …………………………………………………1

1.2 机械无级变速器的特征和应用 ………………………………………………2

1.3 无级变速器的研究现状 ………………………………………………………3

1.4 毕业设计内容和要求 …………………………………………………………3

第二章 无级变速总体方案 …………………………………………………………5

2.1 钢球长锥式(RC型)无级变速器 ……………………………………………5

2.2 钢球外锥式无级变速器 ………………………………………………………5

2.3 两类型的比较与选择 ………………………………………………………… 7

第三章 钢球外锥式无级变速器部分零件的设计与计算 ……………………9

3.1 钢球与主、从动锥轮的计算与设计 …………………………………………9

3.2 加压盘的设计与计算 …………………………………………………………10

3.3 调速齿轮上的变速曲线槽的设计与计算 ……………………………………12

3.4 输入轴的设计与计算 …………………………………………………………13

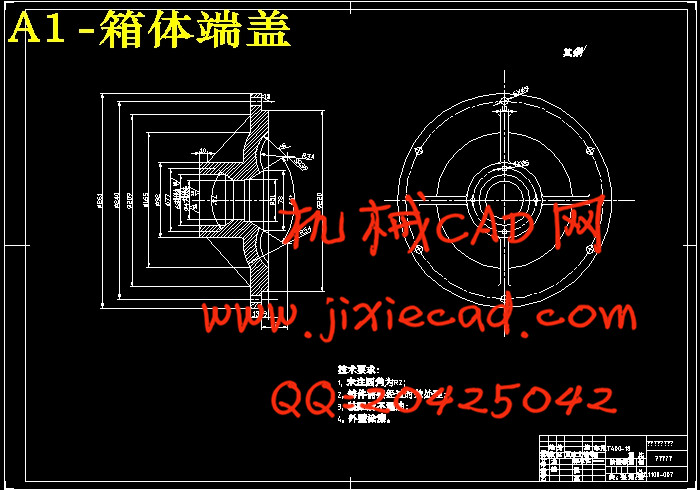

3.5 端盖的设计与计算 ……………………………………………………………15

3.6 调速机构的设计与计算 ………………………………………………………16

第四章 主要零件的校核 ……………………………………………………………18

4.1 输出、输入轴的校核 …………………………………………………………18

4.2 轴承的校核 ……………………………………………………………………20

4.3 键的校核 ………………………………………………………………………21

第五章 无极变速器的装配……………………………………………………………24

设计总结 ……………………………………………………………………………25

致谢 ……………………………………………………………………………………… 26

参考文献……………………………………………………………………………………27

摘要:机械无级变速器是一种能适应工艺要求多变、工艺流程机械化和自动化发展以及改善机械工作性能的一种通用传动装置。本文简要介绍了摩擦式机械无级变速器的基本结构、设计计算的方法、材质及润滑等方面的知识,并以此作为本次无级变速器设计的理论基础。

本设计采用的是以钢球锥轮作为中间传动元件,通过改变钢球的工作半径来实现输出轴转速连续变化的钢球锥轮式无级变速器。本文分析了在传动过程中变速器的主、从动轮,钢球和外环的工作原理和受力关系;详细推导了实用的钢球锥轮式无级变速器设计的计算公式;并针对设计所选择的参数进行了具体的设计计算;绘制了所计算的钢球锥轮式无级变速器的装配图和主要传动元件的零件图,将此变速器的结构和工艺等方面的要求表达得更为清楚。

这种无级变速器有良好的结构和性能优势,具有很强的实用价值,完全可以作为批量生产的无级变速器。其主要特点是:1.变速范围较宽;2.恒功率特性好;3.可以升、降速,正、反转。4.运转平稳,抗冲击能力较强;5.输出功率较大;6.使用寿命长;7.调速简单,工作可靠;8.容易维修。

关键词:无级变速器,摩擦式,钢球锥轮式,设计。

Small power machinery variator structure design

Abstract: The mechanical variable speed drives is a general purpose gearing which can accommodate the variable requirements of the process planning, mechanization of the schedule drawing ,the development of automation and the improvement of the mechanical working capabilities. The article briefly introduce the basic structure, the way of design and calculation, material and lubricate of the frication type variable speed drives, and taking them as the theory basis of the design of mechanical variable speed drives.

This design uses the ball pyramid wheel as the middle transmission component, by changing its’ working radius to realize the continuous change of the output axis. This article analyzes the working theory and the working forces of the drive wheel, ball wheel and outer ring during the transmission process. It also deduces the practical calculation formula of the ball pyramid wheel type variable speed drives, it also goes on the material calculation aim at the selection parameter. It protracts the assemble-drawing of the ball pyramid wheel type variable speed drives and the accessory-drawing of the mostly drive component. So it can express more clearly of the structure and process planning of the variable speed drives.

The variable speed drives has good structure and properties, and it can use as batch production. The most specialties: 1 wide range of variable speed;2 the constant output power;3 it can rotate positively and versedly;4 stable accuracy of speed;5 high output power;6 long life;7 simply and precise control of speed;8 easy maintain.

Keywords: CVT,friction type,ball pyramid type,design.

目 录

摘要 ………………………………………………………………………………………Ⅱ

Abstract……………………………………………………………………………………Ⅲ

第一章 绪论 ………………………………………………………………………………1

1.1 机械无级变速器的发展概况 …………………………………………………1

1.2 机械无级变速器的特征和应用 ………………………………………………2

1.3 无级变速器的研究现状 ………………………………………………………3

1.4 毕业设计内容和要求 …………………………………………………………3

第二章 无级变速总体方案 …………………………………………………………5

2.1 钢球长锥式(RC型)无级变速器 ……………………………………………5

2.2 钢球外锥式无级变速器 ………………………………………………………5

2.3 两类型的比较与选择 ………………………………………………………… 7

第三章 钢球外锥式无级变速器部分零件的设计与计算 ……………………9

3.1 钢球与主、从动锥轮的计算与设计 …………………………………………9

3.2 加压盘的设计与计算 …………………………………………………………10

3.3 调速齿轮上的变速曲线槽的设计与计算 ……………………………………12

3.4 输入轴的设计与计算 …………………………………………………………13

3.5 端盖的设计与计算 ……………………………………………………………15

3.6 调速机构的设计与计算 ………………………………………………………16

第四章 主要零件的校核 ……………………………………………………………18

4.1 输出、输入轴的校核 …………………………………………………………18

4.2 轴承的校核 ……………………………………………………………………20

4.3 键的校核 ………………………………………………………………………21

第五章 无极变速器的装配……………………………………………………………24

设计总结 ……………………………………………………………………………25

致谢 ……………………………………………………………………………………… 26

参考文献……………………………………………………………………………………27