设计简介

固体混合是工业生产过程中一种重要的单元操作,它广泛用于化工、医药、食品、饲料、塑料和建材等部门。随着固体混合技术的发展,各种不同类型的混合设备也在不断地创新。按对粉粒体作用力的方式分为容器回转型、容器固定型和复合型混合设备。

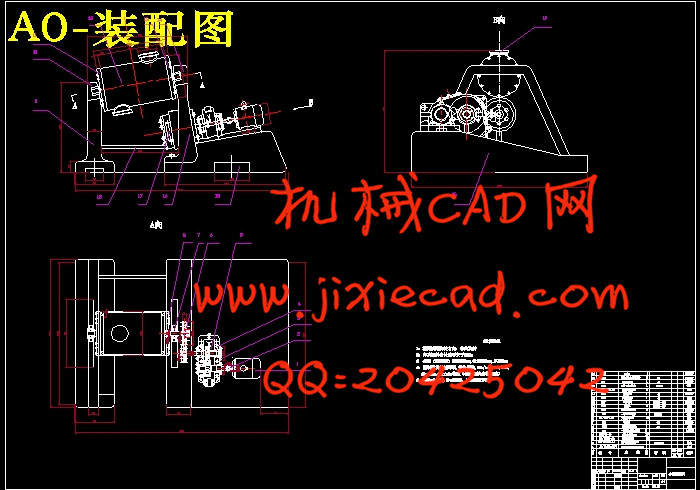

介绍了容器回转型倾斜式混料机的工作原理和结构特点,在分析了混料机国内外发展现状的基础上,完成了混料机的总体设计。具体设计了传动装置,达到四级变速的混料要求,重点对轴、齿轮、轴承进行了详细设计。小型混料机具有高效、节能、低污染、操作简便等诸多优越性能,满足了生产需要。

关键词 固体混合 混料机 结构特点 发展方向

Abstract

The solid mixture is an important unit operation in the processes of industrial production; it is widely used in chemical, pharmaceutical, food, plastics and building materials sectors. With the development of solid hybrid technology, different types of mixing equipment are also constantly innovating. By way of physical force to the powder, it can be divided into container back in transition, the container fixed and composite mixing equipment;

The article introduced the principle and structure of the tilt container back in transition mixer. The design of the mixer is completed, based on the analysis of mixer current development status. Specific design is the transmission device with its mixing speed achieves to four, especially, the shafts, gears, bearings are designed in detail. Small mixer with high efficiency, energy saving, low pollution, easy operation and many other advantages can meet the production needs.

Keywords solid mixture, mixer, structural characteristics,

development

目 次

1 绪论…………………………………………………………………………………1

1.1固体粒子混合……………………………………………………………………1

1.1.1 固体粒子………………………………………………………………………1

1.1.2 固体混合……………………………………………………………………2

1.1.3 固体混合的影响因素 ………………………………………………………2

1.2 混合设备的分类…………………………………………………………………3

1.2.1 容器回转型混合设备…………………………………………………………3

1.2.2 容器固定型混合设备…………………………………………………………4

1.2.3. 复合型混合设备……………………………………………………………4

2. 混料机的组成及各部分功能……………………………………………………6

2.1 混料机的组成……………………………………………………………………6

2.2 混料机的各部分功能……………………………………………………………7

3 .电动机的选用……………………………………………………………………9

3.1 电动机选用原则…………………………………………………………………9

3.2 电动机选择计算………………………………………………………………14

4.混料机传动装置的设计…………………………………………………………17

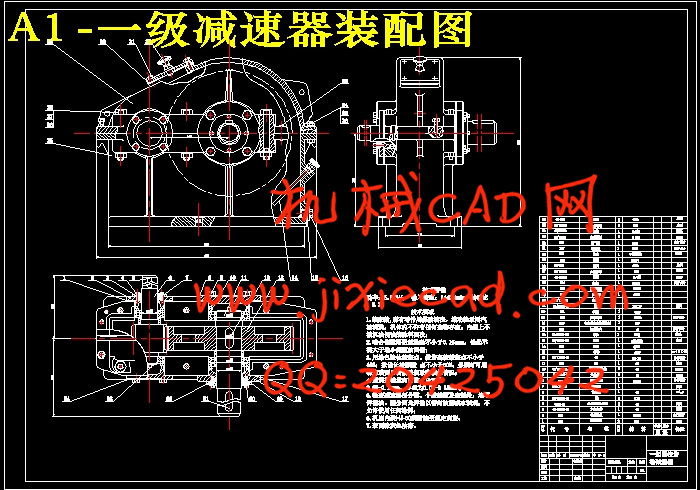

4.1减速器的设计…………………………………………………………………17

4.1.1 确定传动装置总传动比和分配各级传动比……………………………17

4.1.2 传动装置的运动和动力参数………………………………………………17

4.1.3 传动零件的设计计算………………………………………………………18

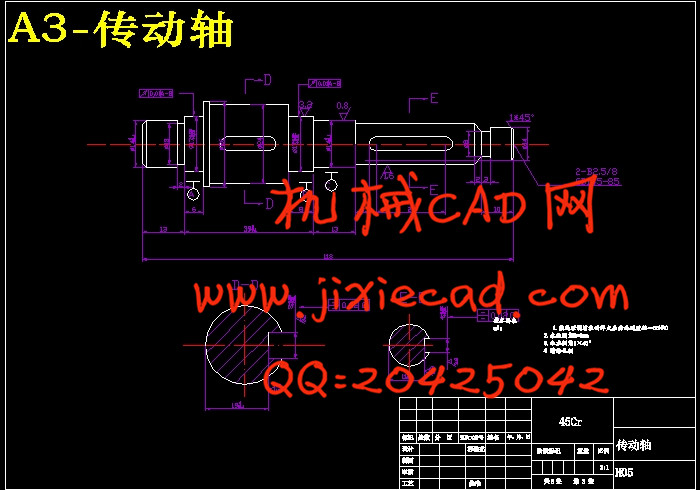

4.1.4 轴的结构设计计算及校核…………………………………………………22

4.1.5 键联接的选择及计算………………………………………………………29

4.1.6 滚动轴承的寿命校核………………………………………………………29

4.2联轴器的选用…………………………………………………………………30

4.3 变速装置的设计………………………………………………………………31

4.4传动齿轮箱的设计……………………………………………………………32

4.4.1 轴的设计……………………………………………………………………32

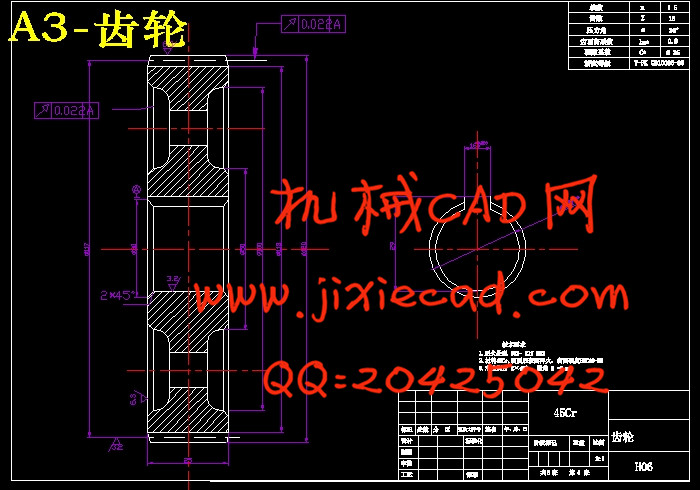

4.4.2 齿轮的设计…………………………………………………………………33

4.4.3 轴承的选用…………………………………………………………………34

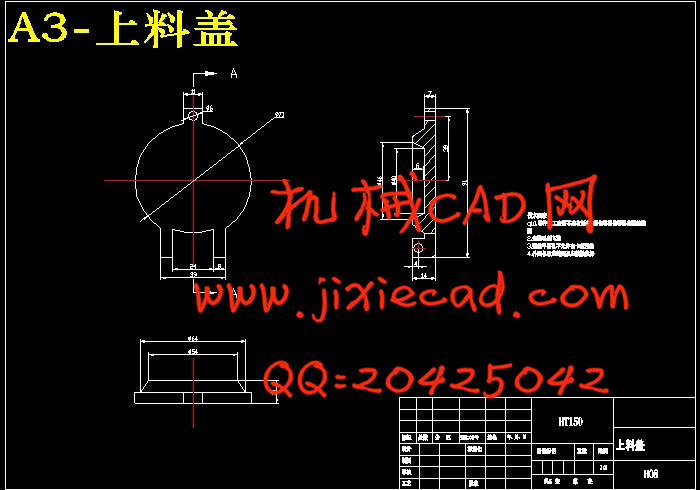

4.4.4 下箱体与上箱盖的设计……………………………………………………35

5.混料滚筒的设计…………………………………………………………………36

6.混料机机架设计…………………………………………………………………37

结论…………………………………………………………………………………39

致谢…………………………………………………………………………………40

参考文献……………………………………………………………………………41

介绍了容器回转型倾斜式混料机的工作原理和结构特点,在分析了混料机国内外发展现状的基础上,完成了混料机的总体设计。具体设计了传动装置,达到四级变速的混料要求,重点对轴、齿轮、轴承进行了详细设计。小型混料机具有高效、节能、低污染、操作简便等诸多优越性能,满足了生产需要。

关键词 固体混合 混料机 结构特点 发展方向

Abstract

The solid mixture is an important unit operation in the processes of industrial production; it is widely used in chemical, pharmaceutical, food, plastics and building materials sectors. With the development of solid hybrid technology, different types of mixing equipment are also constantly innovating. By way of physical force to the powder, it can be divided into container back in transition, the container fixed and composite mixing equipment;

The article introduced the principle and structure of the tilt container back in transition mixer. The design of the mixer is completed, based on the analysis of mixer current development status. Specific design is the transmission device with its mixing speed achieves to four, especially, the shafts, gears, bearings are designed in detail. Small mixer with high efficiency, energy saving, low pollution, easy operation and many other advantages can meet the production needs.

Keywords solid mixture, mixer, structural characteristics,

development

目 次

1 绪论…………………………………………………………………………………1

1.1固体粒子混合……………………………………………………………………1

1.1.1 固体粒子………………………………………………………………………1

1.1.2 固体混合……………………………………………………………………2

1.1.3 固体混合的影响因素 ………………………………………………………2

1.2 混合设备的分类…………………………………………………………………3

1.2.1 容器回转型混合设备…………………………………………………………3

1.2.2 容器固定型混合设备…………………………………………………………4

1.2.3. 复合型混合设备……………………………………………………………4

2. 混料机的组成及各部分功能……………………………………………………6

2.1 混料机的组成……………………………………………………………………6

2.2 混料机的各部分功能……………………………………………………………7

3 .电动机的选用……………………………………………………………………9

3.1 电动机选用原则…………………………………………………………………9

3.2 电动机选择计算………………………………………………………………14

4.混料机传动装置的设计…………………………………………………………17

4.1减速器的设计…………………………………………………………………17

4.1.1 确定传动装置总传动比和分配各级传动比……………………………17

4.1.2 传动装置的运动和动力参数………………………………………………17

4.1.3 传动零件的设计计算………………………………………………………18

4.1.4 轴的结构设计计算及校核…………………………………………………22

4.1.5 键联接的选择及计算………………………………………………………29

4.1.6 滚动轴承的寿命校核………………………………………………………29

4.2联轴器的选用…………………………………………………………………30

4.3 变速装置的设计………………………………………………………………31

4.4传动齿轮箱的设计……………………………………………………………32

4.4.1 轴的设计……………………………………………………………………32

4.4.2 齿轮的设计…………………………………………………………………33

4.4.3 轴承的选用…………………………………………………………………34

4.4.4 下箱体与上箱盖的设计……………………………………………………35

5.混料滚筒的设计…………………………………………………………………36

6.混料机机架设计…………………………………………………………………37

结论…………………………………………………………………………………39

致谢…………………………………………………………………………………40

参考文献……………………………………………………………………………41