设计简介

小型混凝土搅拌机的设计

摘要 目前,混凝土搅拌机在国内外都有着飞速的发展,国际竞争力在不断提高。

为了满足市场需求,完善产品系列,适应小型建筑施工和实验室工作的需求,设

计了此混凝土搅拌机。

本课题主要研究立轴式混凝土搅拌机的工作原理以及搅拌机搅拌系统方案设计。根据设计要求,对混凝土搅拌机的搅拌系统初步定型,并对搅拌系统的主要部件进行设计和计算。主要设计结论如下:

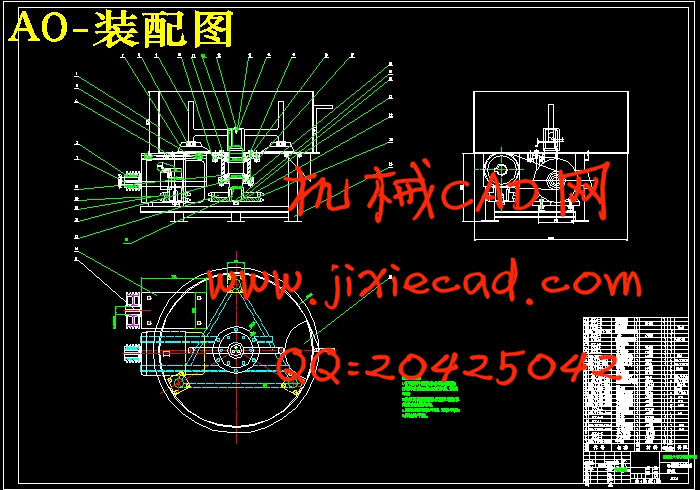

(1)搅拌机的结构方案分析与总体设计

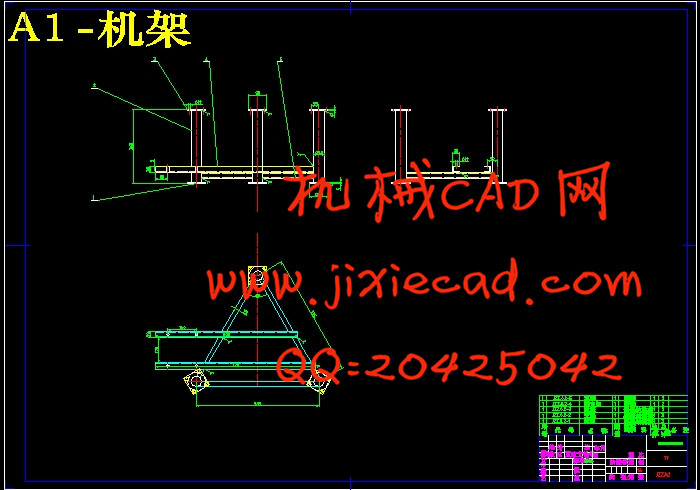

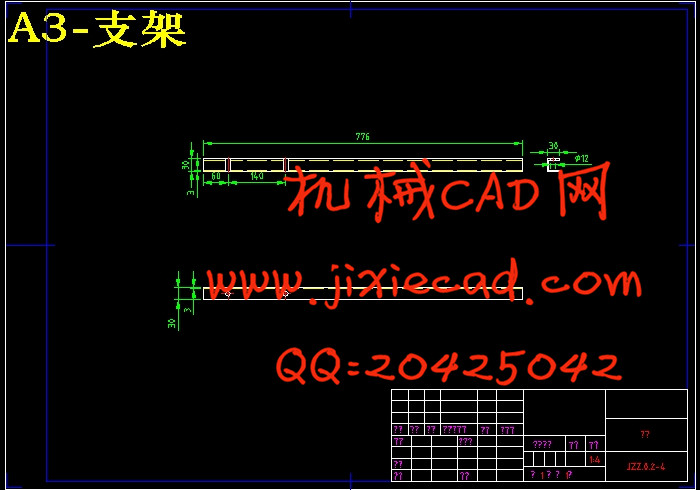

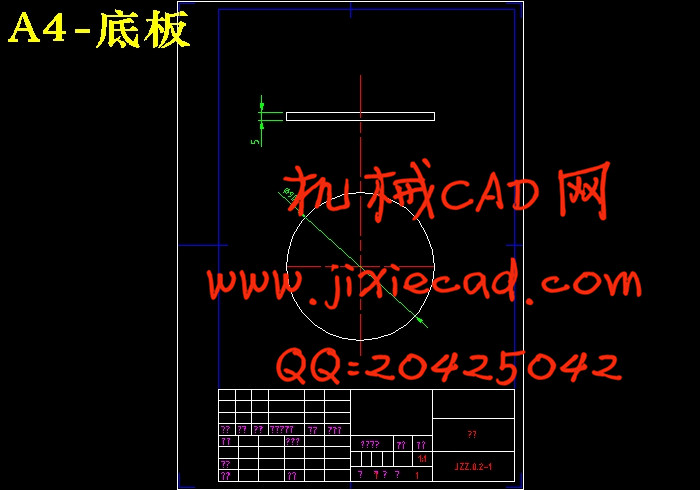

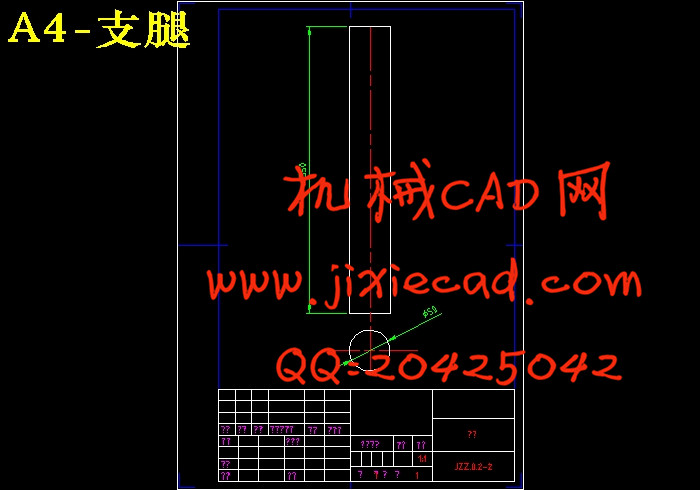

本搅拌机的结构是由机架、搅拌装置、传动系统所主成。 机架是整个设备的支撑部分,由槽钢和钢管焊接而成。搅拌装置由搅拌筒、搅拌轴、搅拌铲片所主成,搅拌铲片固定在搅拌臂上,并且与搅拌轴主成一体,搅拌铲与搅拌筒底间隙可微量调整。传动系统由电动机、减速器、带传动、链传动所组成。

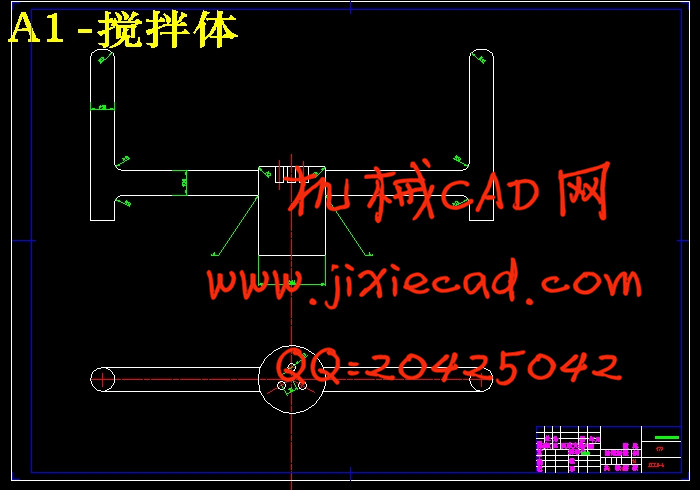

(2)搅拌装置的设计

搅拌装置是安装在轴套上的铲片式叶片,叶片随轴的旋转而转动,对筒内物料进行搅拌,是物料混合均匀,搅拌臂向上伸出,可起到搅拌上方物料的作用。

(3)传动系统的设计

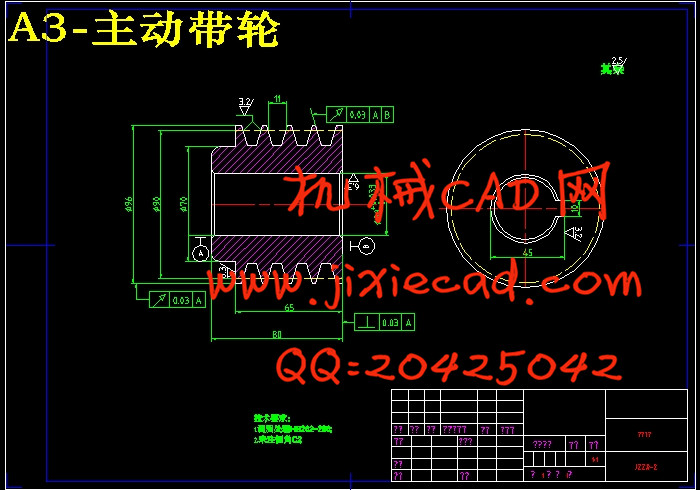

传动系统是由V带传动和链传动来传递运动的。电动机输出转速通过V带传动传递到减速器,减速器又通过链传动将转速传递给搅拌机的主轴,主轴带动轴套转动,从而使搅拌叶片旋转,来完成搅拌的工作。

关键词 搅拌机 立轴 混凝土

Small concrete mixer design

Abstract

At present, concrete mixer at home and abroad have a rapid development, international competitiveness in the continuous high. In order to meet market demands, improving the product series, adapt to the small building construction and laboratory work demand, design the concrete mixer.

This topic research vertical shaft type concrete mixer work principle and blender mixing system design. According to the requirements of the design of concrete mixer, the mixing system, and the preliminary finalize the design of the main parts by mixing system design and calculation. The main conclusions are as follows:

(1) mixer with the overall structural design of program analysis

The structure is a rack mixer, mixing equipment, drive into the main.

The support of the entire equipment rack is part of the channel steel and steel pipe welded. Mixing device consists of the mixing tube, shaft, mixing shovel intand with the main shaft into one, Spatula and mixing tube at the end of the gap can be micro-adjusted. Transmission from the motor, gearbox, belt drive, chain drive of the composition.

(2) mixing device design

Mixing device is installed in the sleeve piece on the shovel blade, blade rotation with the axis of rotation of the barrel for mixing the material, the material is mixed, stirring arm extended upward, may play a role in mixing the material above.

(3) transmission system design

Transmission by V belt drive and chain drive to transfer movement. Motor output speed to pass through the V-belt transmission to the gearbox, gearbox and chain drive to speed to pass through to the mixer spindle drive shaft rotation, so that the mixing blades rotating, stirring to complete the work.

Keywords Mixer Vertical axis Concreteo a film by Lord Spatula piece fixed to the mixing arm,

目录

摘要

Small concrete mixer design

1 引言 - 1 -

1.1 项目研究的目的意义 - 1 -

1.1.1混凝土的组成 - 2 -

1.1.2搅拌的任务 - 2 -

1.1.3搅拌机设计的意义 - 2 -

1.2 国内外混凝土搅拌机的发展状况 - 3 -

1.3设计内容 - 4 -

2 设计计算说明书(SS) -5 -

2.1 总体设计方案 - 5 -

3.1.1混凝土搅拌机种类和功能比较 -5 -

3.1.2混凝土搅拌机的结构型式选择 -6 -

2.2总体结构及工作 -6 -

2.2.1结构组成及工作原理 -6 -

2.2.2主要技术参数 -7 -

2.3主要工作部件的设计 - 8 -

2.3.1搅拌装置的设计 8 -

2.3.2机架的设计 - 9 -

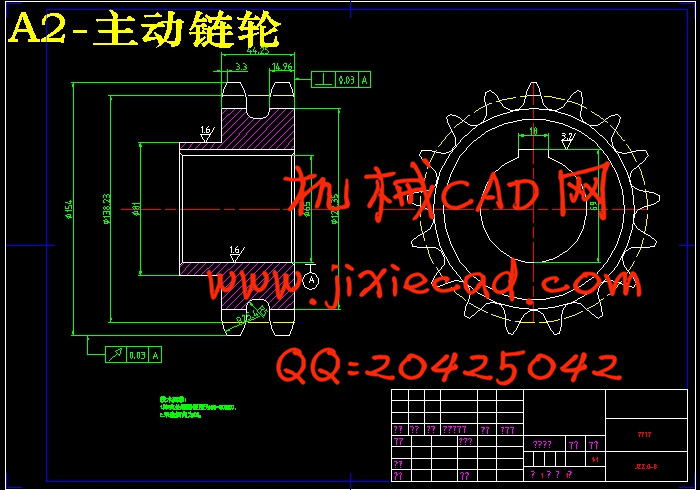

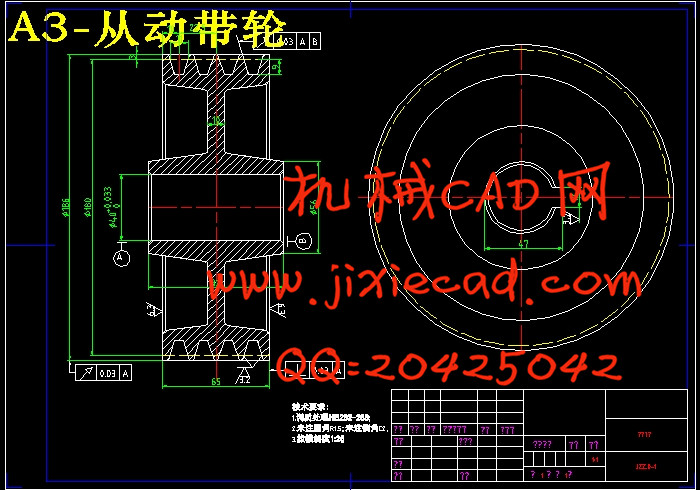

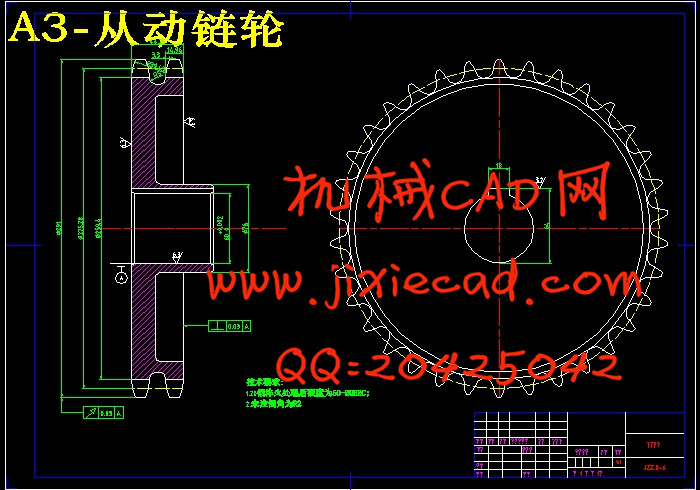

23.4传动系统的设计 - 9-

2.4.1传动比分配及电动机选型 - 9 -

2.4.2 V带传动的设计 - 10 -

2.4.3减速器选型 - 15 -

2.4.4链传动的设计 - 15 -

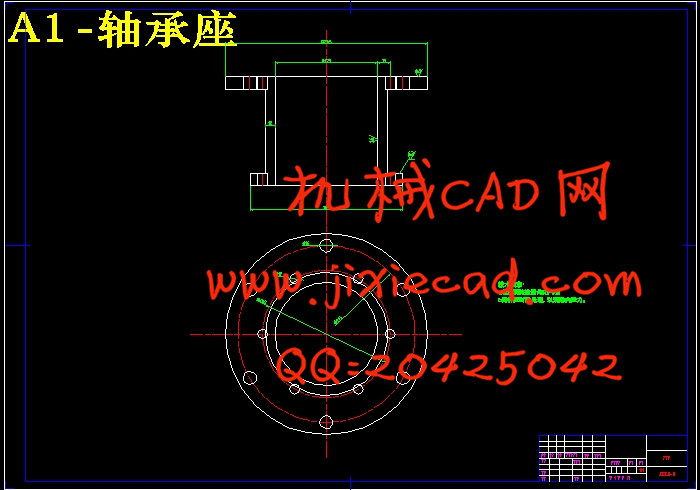

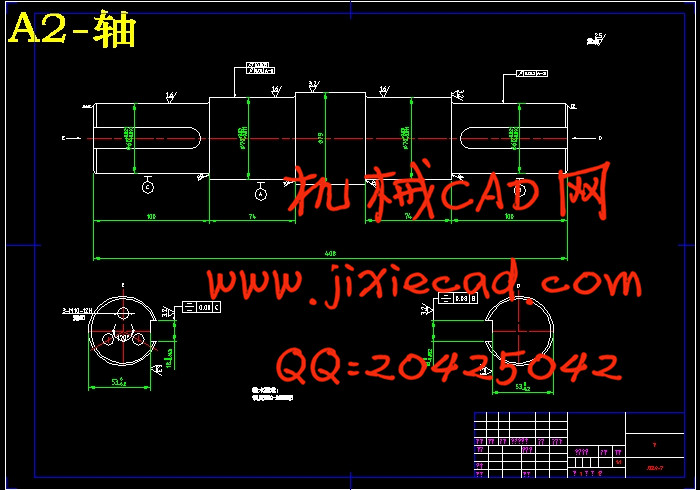

2.5主轴设计与计算 - 17 -

2.5.1轴的计算过程 -17 -

2.5.2键与轴承的选择 - 18-

2.5.3轴的强度校核 - 19 -

2.5.4轴承组合的设计 - 22 -

3 使用说明书(SM) - 23 -

3.1型号及名称 - 23 -

3.2主要结构及工作原理 - 23 -

3.2.1结构组成 - 23 -

3.2.2主要技术参数 - 24-

3.3使用、维护与保养 - 25 -

3.4安全操作规程 - 25 -

4 技术条件(JT) - 26 -

4.1 检验规则 - 26 -

4.1.1检验的划分 -26 -

4.1.2出厂检验 - 26-

4.1.3型式检验 - 27 -

5 结论 - 28 -

参考文献 - 29 -

致谢 - 30 -

摘要 目前,混凝土搅拌机在国内外都有着飞速的发展,国际竞争力在不断提高。

为了满足市场需求,完善产品系列,适应小型建筑施工和实验室工作的需求,设

计了此混凝土搅拌机。

本课题主要研究立轴式混凝土搅拌机的工作原理以及搅拌机搅拌系统方案设计。根据设计要求,对混凝土搅拌机的搅拌系统初步定型,并对搅拌系统的主要部件进行设计和计算。主要设计结论如下:

(1)搅拌机的结构方案分析与总体设计

本搅拌机的结构是由机架、搅拌装置、传动系统所主成。 机架是整个设备的支撑部分,由槽钢和钢管焊接而成。搅拌装置由搅拌筒、搅拌轴、搅拌铲片所主成,搅拌铲片固定在搅拌臂上,并且与搅拌轴主成一体,搅拌铲与搅拌筒底间隙可微量调整。传动系统由电动机、减速器、带传动、链传动所组成。

(2)搅拌装置的设计

搅拌装置是安装在轴套上的铲片式叶片,叶片随轴的旋转而转动,对筒内物料进行搅拌,是物料混合均匀,搅拌臂向上伸出,可起到搅拌上方物料的作用。

(3)传动系统的设计

传动系统是由V带传动和链传动来传递运动的。电动机输出转速通过V带传动传递到减速器,减速器又通过链传动将转速传递给搅拌机的主轴,主轴带动轴套转动,从而使搅拌叶片旋转,来完成搅拌的工作。

关键词 搅拌机 立轴 混凝土

Small concrete mixer design

Abstract

At present, concrete mixer at home and abroad have a rapid development, international competitiveness in the continuous high. In order to meet market demands, improving the product series, adapt to the small building construction and laboratory work demand, design the concrete mixer.

This topic research vertical shaft type concrete mixer work principle and blender mixing system design. According to the requirements of the design of concrete mixer, the mixing system, and the preliminary finalize the design of the main parts by mixing system design and calculation. The main conclusions are as follows:

(1) mixer with the overall structural design of program analysis

The structure is a rack mixer, mixing equipment, drive into the main.

The support of the entire equipment rack is part of the channel steel and steel pipe welded. Mixing device consists of the mixing tube, shaft, mixing shovel intand with the main shaft into one, Spatula and mixing tube at the end of the gap can be micro-adjusted. Transmission from the motor, gearbox, belt drive, chain drive of the composition.

(2) mixing device design

Mixing device is installed in the sleeve piece on the shovel blade, blade rotation with the axis of rotation of the barrel for mixing the material, the material is mixed, stirring arm extended upward, may play a role in mixing the material above.

(3) transmission system design

Transmission by V belt drive and chain drive to transfer movement. Motor output speed to pass through the V-belt transmission to the gearbox, gearbox and chain drive to speed to pass through to the mixer spindle drive shaft rotation, so that the mixing blades rotating, stirring to complete the work.

Keywords Mixer Vertical axis Concreteo a film by Lord Spatula piece fixed to the mixing arm,

目录

摘要

Small concrete mixer design

1 引言 - 1 -

1.1 项目研究的目的意义 - 1 -

1.1.1混凝土的组成 - 2 -

1.1.2搅拌的任务 - 2 -

1.1.3搅拌机设计的意义 - 2 -

1.2 国内外混凝土搅拌机的发展状况 - 3 -

1.3设计内容 - 4 -

2 设计计算说明书(SS) -5 -

2.1 总体设计方案 - 5 -

3.1.1混凝土搅拌机种类和功能比较 -5 -

3.1.2混凝土搅拌机的结构型式选择 -6 -

2.2总体结构及工作 -6 -

2.2.1结构组成及工作原理 -6 -

2.2.2主要技术参数 -7 -

2.3主要工作部件的设计 - 8 -

2.3.1搅拌装置的设计 8 -

2.3.2机架的设计 - 9 -

23.4传动系统的设计 - 9-

2.4.1传动比分配及电动机选型 - 9 -

2.4.2 V带传动的设计 - 10 -

2.4.3减速器选型 - 15 -

2.4.4链传动的设计 - 15 -

2.5主轴设计与计算 - 17 -

2.5.1轴的计算过程 -17 -

2.5.2键与轴承的选择 - 18-

2.5.3轴的强度校核 - 19 -

2.5.4轴承组合的设计 - 22 -

3 使用说明书(SM) - 23 -

3.1型号及名称 - 23 -

3.2主要结构及工作原理 - 23 -

3.2.1结构组成 - 23 -

3.2.2主要技术参数 - 24-

3.3使用、维护与保养 - 25 -

3.4安全操作规程 - 25 -

4 技术条件(JT) - 26 -

4.1 检验规则 - 26 -

4.1.1检验的划分 -26 -

4.1.2出厂检验 - 26-

4.1.3型式检验 - 27 -

5 结论 - 28 -

参考文献 - 29 -

致谢 - 30 -