设计简介

摘要

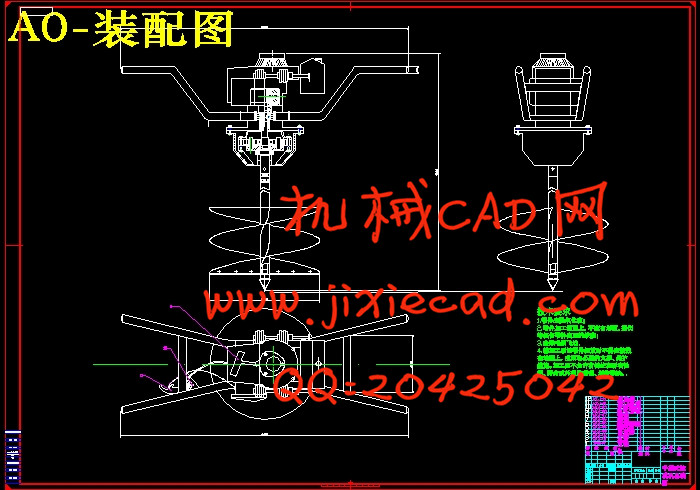

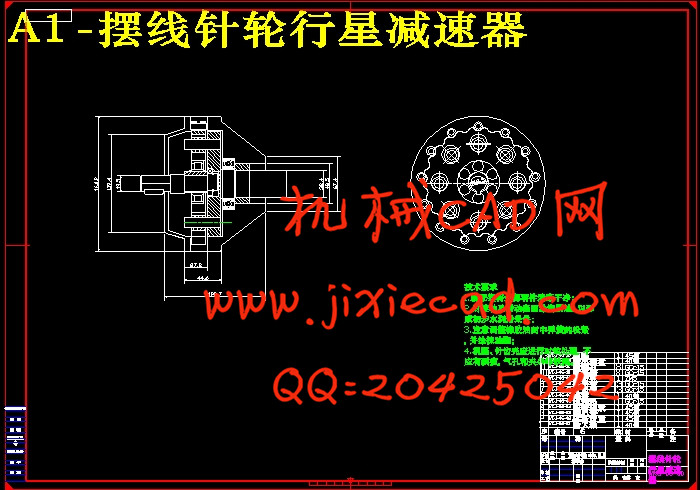

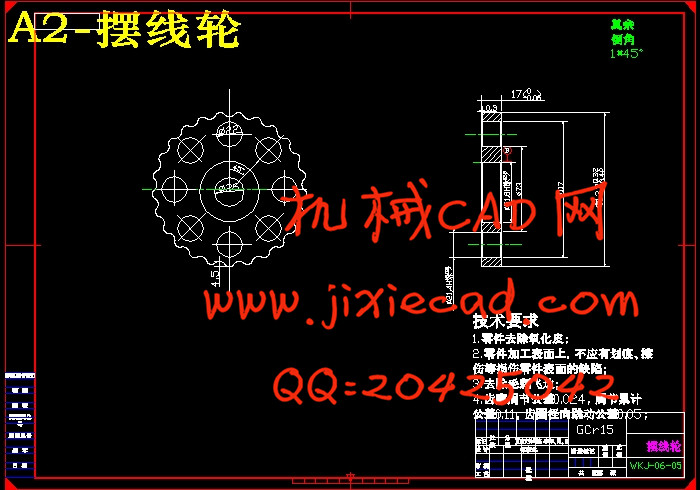

本文介绍了手提式挖坑机的相关背景、国内外研究现状、挖坑机的设计要求及其类型、工作原 理、技术性能。通过对原始数据的分析比较、方案的论证以及综合考虑,完成了手提式挖坑机的总体 设计。在此基础上对手提式挖坑机从结构原理、动力选择 、离合器的设计、螺旋钻头的设计、减速器 设计进行阐述。摆线针轮行星减速器作为重要的机械传动部件具有体积小、重量轻、传动效率高的特 点。本设计在全面考虑多齿啮合、运转平稳、轮齿均载等运动学和动力学的要求,实现高承载能力、 高传递效率、高可靠性和优良动力学性能等指标,而且要便于制造、装配和检修,设计了该具有合理 结构的摆线针轮行星减速器。

本设计建立了合理的动力分析数学模型,对摆线针轮传动中的摆线轮、转臂轴承、柱销及轴进行 准确的受力分析,并其求解。计算并校核主要件的强度及转臂轴承、各支承轴承的寿命,分析结果可 以看到,各轴承性能指标均符合要求。

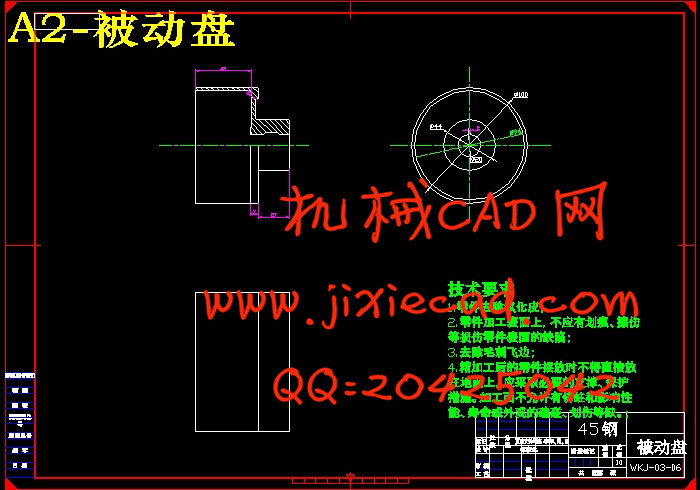

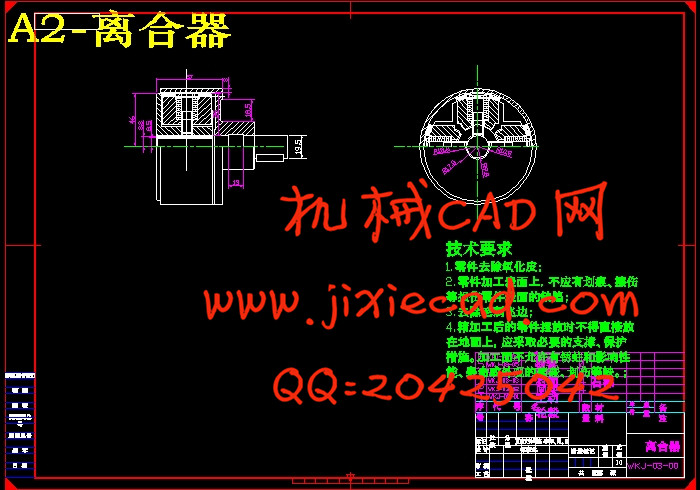

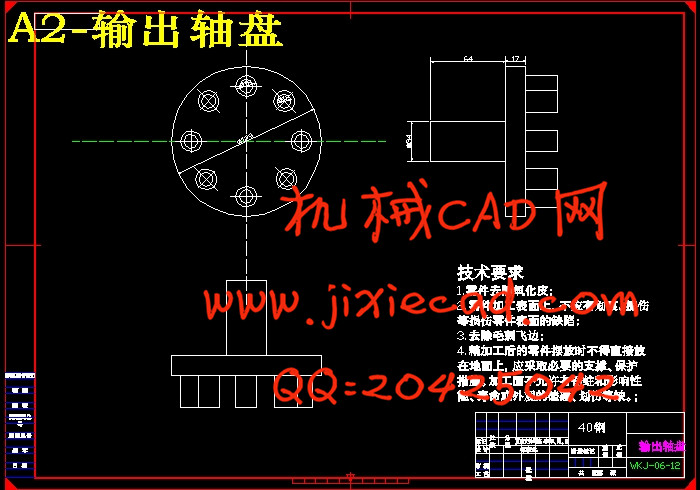

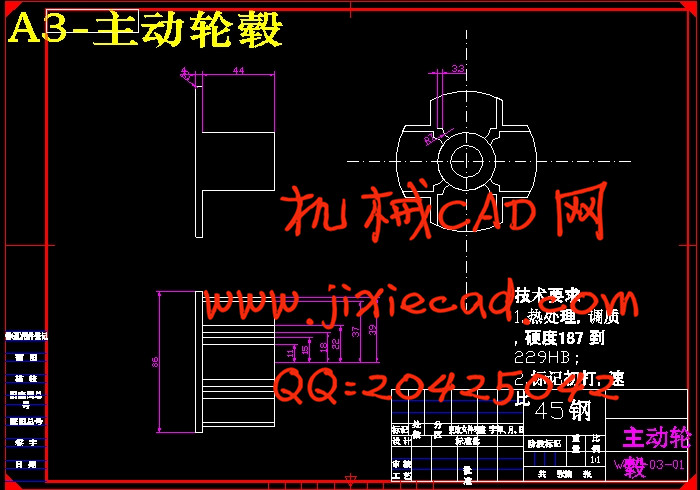

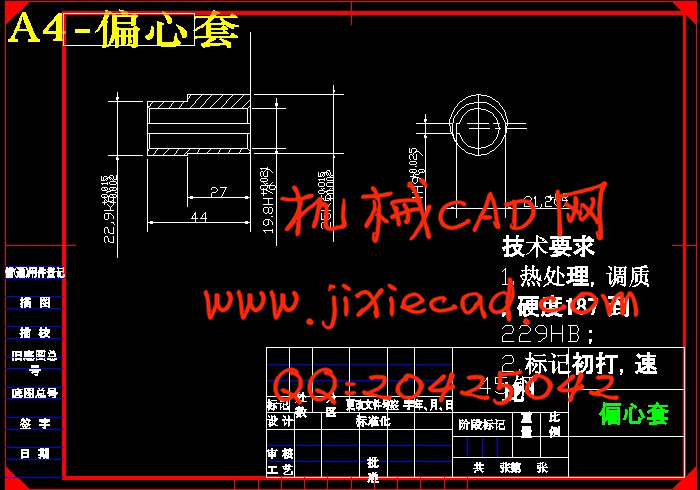

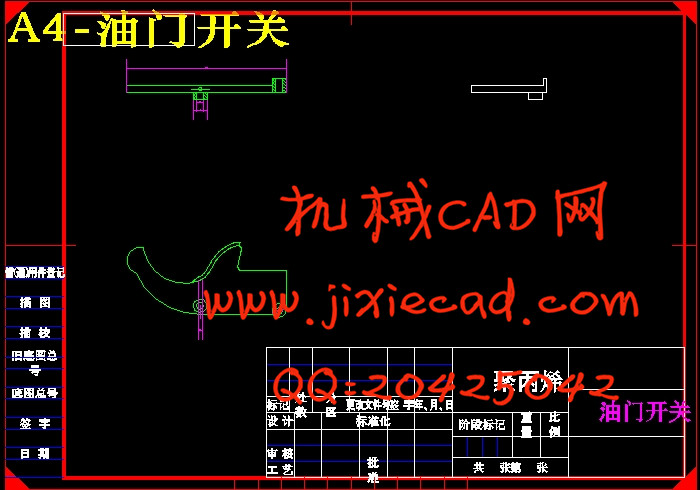

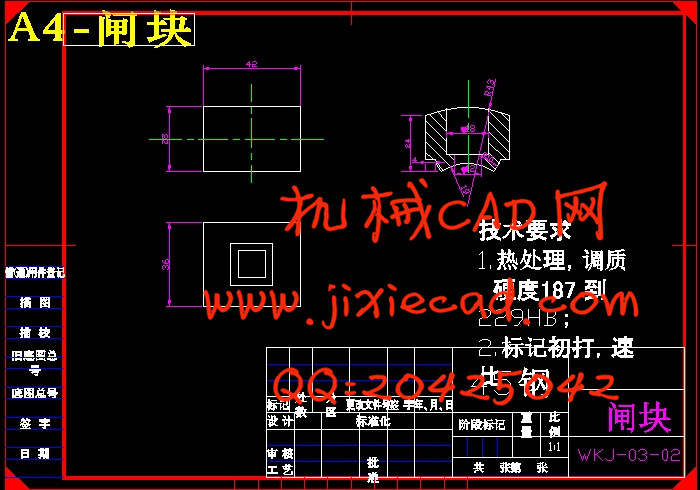

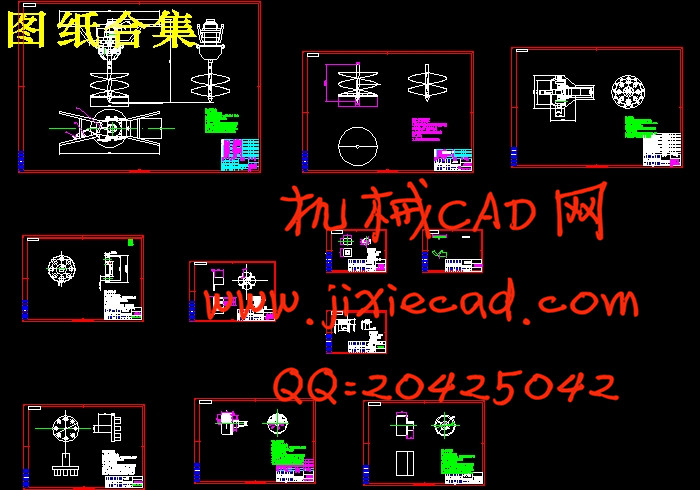

利用Auto CAD软件对摆线针轮减速器各零件建立几何三维模型、摆线针轮减速器虚拟装配及工程 图生成。用本文的方法设计摆线针轮减速器,具有设计快捷、方便等特点。研究结果对提高设计的速 度、质量具有重要意义。

Abstract:本文介绍了手提式挖坑机的相关背景、国内外研究现状、挖坑机的设计要求及其类型、工作原 理、技术性能。通过对原始数据的分析比较、方案的论证以及综合考虑,完成了手提式挖坑机的总体 设计。在此基础上对手提式挖坑机从结构原理、动力选择 、离合器的设计、螺旋钻头的设计、减速器 设计进行阐述。摆线针轮行星减速器作为重要的机械传动部件具有体积小、重量轻、传动效率高的特 点。本设计在全面考虑多齿啮合、运转平稳、轮齿均载等运动学和动力学的要求,实现高承载能力、 高传递效率、高可靠性和优良动力学性能等指标,而且要便于制造、装配和检修,设计了该具有合理 结构的摆线针轮行星减速器。

本设计建立了合理的动力分析数学模型,对摆线针轮传动中的摆线轮、转臂轴承、柱销及轴进行 准确的受力分析,并其求解。计算并校核主要件的强度及转臂轴承、各支承轴承的寿命,分析结果可 以看到,各轴承性能指标均符合要求。

利用Auto CAD软件对摆线针轮减速器各零件建立几何三维模型、摆线针轮减速器虚拟装配及工程 图生成。用本文的方法设计摆线针轮减速器,具有设计快捷、方便等特点。研究结果对提高设计的速 度、质量具有重要意义。

This article introduces the portable digger including the relevant background , overseas and domestic research status , the design requirements and the type of the digger , operating principle , technical characteristic 。 By analysising and comparing the the original data,The cycloid—gear reducer is one of the most important transmission components of the pumping unit by its smaller volume , lighter weight and effective transmission. In order to realize four targets which include high transmission efficiency, high reliability and the excellent dynamics performance and guarantee credible lubricate ability, receive high efficiency of transmission, and make it easy for manufacture, assembly and inspection, we thought over all the requests in the round and design the rational structure cycloid—gear reducer.

In this design,we built the exact force analysis mathematical

model of the cycloid—gear reducer, analyzed the forces born by the cycloid-gear, the bearings and the shaft, and produce the Matlab language software analyze of the forces analysis. We analyzed the forces of parts in the cycloid—gear reducer and calculated the intensity and the life of parts. From analyzed the results, we found the parts are our requests.

When we establish the three—dimensional structure of the Planet—cycloid

Reducer model with the software UG,Carry on visual design and virtual assemble

and drawing paper.The result of study have the guide meaning to accelerate design speed and quantities of the Planet—cycloid Reducer.

目录

1 引言...................................................................................................................................................................... 5

2 方案对比与结构.................................................................................................................................................. 5

2.1 国内外研究现状...................................................................................................................................... 5

2.2 挖坑机的构造.......................................................................................................................................... 7

2.2.1 挖坑机的工作条件...................................................................................................................... 7

2.2.2 挖坑机的分类............................................................................................................................... 7

2.2.3 挖坑机的钻头.............................................................................................................................. 8

3 手提式挖坑机的设计.......................................................................................................................................... 9

3.1 手提式挖坑机的工作原理...................................................................................................................... 9

3.2 动力选择................................................................................................................................................ 11

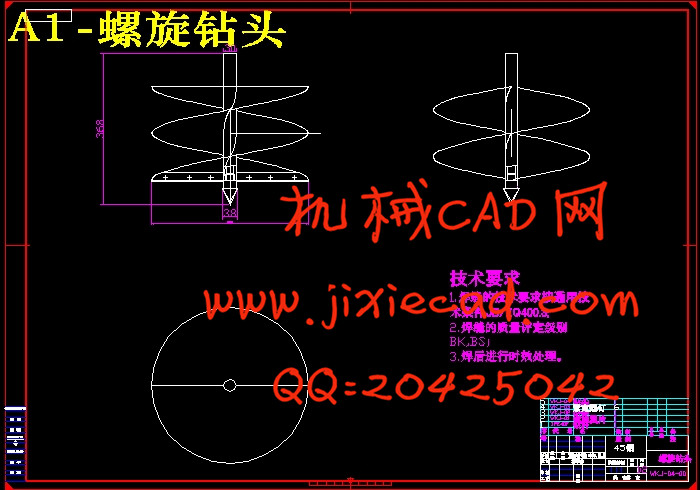

3.3 螺旋钻头的设计和计算......................................................................................................................... 12

3.3.1 螺旋工作面的设计..................................................................................................................... 12

3.3.2 刀片的设计................................................................................................................................ 12

3.3.3 钻尖的设计................................................................................................................................ 13

3.4 离合器的设计.......................................................................................................................................... 14

3.5 减速器的设计.......................................................................................................................................... 22

4 发展趋势............................................................................................................................................................ 32

4.1 一机多能........................................................................................................................................ 32

4.2 人机和谐........................................................................................................................................ 32

4.3 应用范围........................................................................................................................................ 32

参考文献................................................................................................................................................................ 33