设计简介

小型旋耕机

摘 要: 水旱两用旋耕机具有体积小,重量轻,性能好,操作容易,转动方便,适应性广,价格合宜,水旱两用旋耕机机动灵活,一般中小型机械厂、农机厂均可生产制造的要求。如果设计成功,本机可进行旱田旋耕、水田耙整等项作业,能弥补现有旋耕机存在功能较单一、生产效率偏低等不足之处。

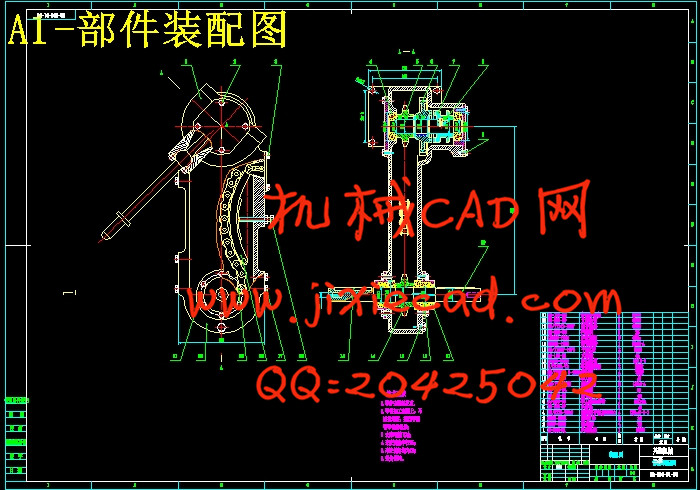

我设计的是一台水旱两用旋耕机,与黄海-12(15)马力手扶拖拉机相匹配,主要用于水田耕整,也可进行旱田耕作。现有的水旱旋耕机是耕幅为0.6米的老式机型,而本课题设计的水旱旋耕机耕幅为1米。

本设计与黄海-12(15)马力手扶拖拉机相匹配,中间传动,固定联接。设计内容包括机架、传动系统、刀辊、尾轮等,要求结构简单、紧凑、重心平衡。该机可用于水田耕整地,也可进行旱田旋耕。各项性能指标应达到国家标准和农艺要求。通过对水田旋耕机驱动轮与土壤相互作用的力学特性的分析,结合水田土壤的力学性质,经过优化设计,研制水旱两用旋耕机驱动轮,使该驱动轮具有良好的动力性能。

关键词: 水田旋耕机;创新设计;驱动轮性能

Design of 1G-100-floods, droughts and dual-use Rotary machine

Abstract:The floods, droughts and dual-use Rotary machine has small size, light weight, performance, and easy to use, easy rotation. it wide adaptability and affordable. Floods, droughts and dual-use rotary machine has tiller-mobile and flexible.Small and medium-sized general machinery factory. The agriculture of factories can manufacturing requirements. If it can successful design, this machine can be floods and drought rotary,and it can rake the whole paddy field’s operations. It can to cover the existing functions of a rotary-existence’s single and low production efficiency, such as inadequate.

I design is one of the floods, droughts and dual-use rotary tiller machine, and it matchs with the Yellow Sea -12 (15) horsepower walking tractor.It not only mainlies for rotary of paddy field, but also for upland farming. The existing floods, droughts and dual-use rotary tiller machine’s rate is the 0.6-metres site in the old models, but the issue of floods, droughts and Rotary machine’s design for the 1-meter site.

The design mach with the Yellow Sea -12 (15) horsepower walking tractor . It makes the middle transmission and fixed link. The design elements include rack, drive system, knife rolls, round tail and so on. It requires frame simple and compact,and it requires the focus of balance. The aircraft not only can be used for paddy’s rotary and formation, but also for upland Rotary. Various performance indicators should meet the state standards and agronomic requirements. Through the driving wheel of paddy fields Rotary interaction with the mechanical properties of the soil analysis, combining the mechanical properties of the soil of paddy field, optimized design, development of floods, droughts and dual-use rotary tiller-driving wheel, so that the driving wheel has a good dynamic performance.

Key words: Floods, droughts and dual-use rotary machine; innovative design;the performace of driving wheel

目录

摘要

Abstract

第一章 引言…………………………………………………………(4)

第二章 总体设计……………………………………………………(5)

2.1设计的内容……………………………………………………………………(5)

2.2设计依据………………………………………………………………………(5)

2.3 设计要求 ……………………………………………………………………(5)

第三章 总体方案论证………………………………………………(7)

3.1中间链传动结构方案的设计…………………………………………………(7)

3.2主要结构和参数的设计与选择计算…………………………………………(7)

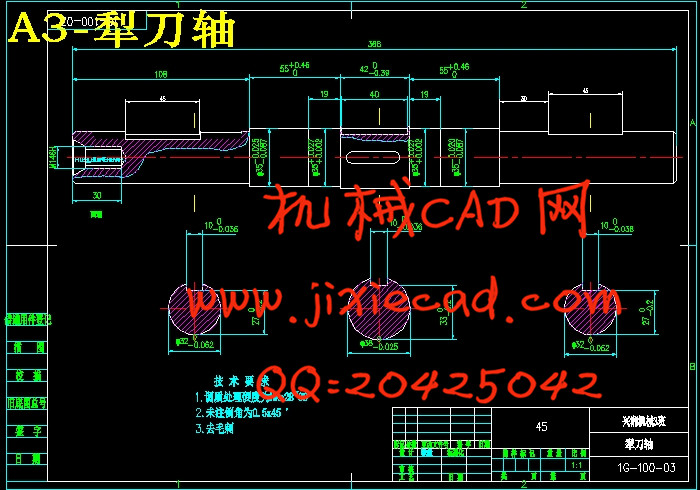

3.3.旋耕刀滚的设计……………………………………………………………(9)

3.4双油封和挡草圈的设计…………………………………………………… (11)

3.5 1G-100旋耕机主要技术规格及基本参数…………………………………(11)

第四章 总体结构的布置与设计……………………………………(12)

4.1 传动结构的设计………………………………………………………………(12)

4.2 主要结构的分析设计…………………………………………………………(12)

第五章 链传动的设计与计算………………………………………(14)

5.1 链传动的设计计算………………………………………………………… (14)

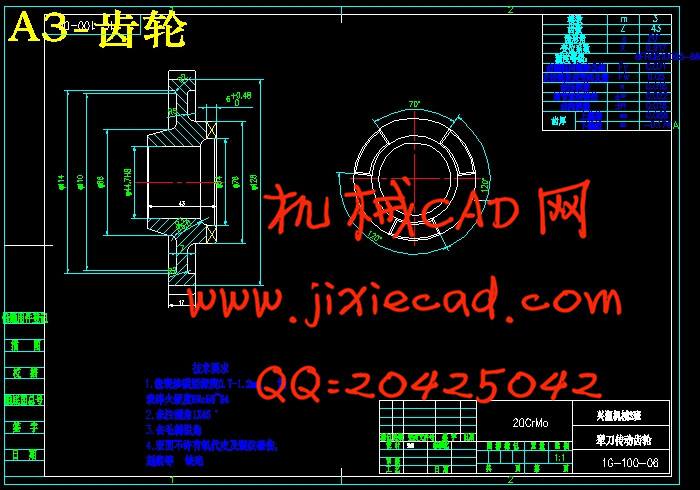

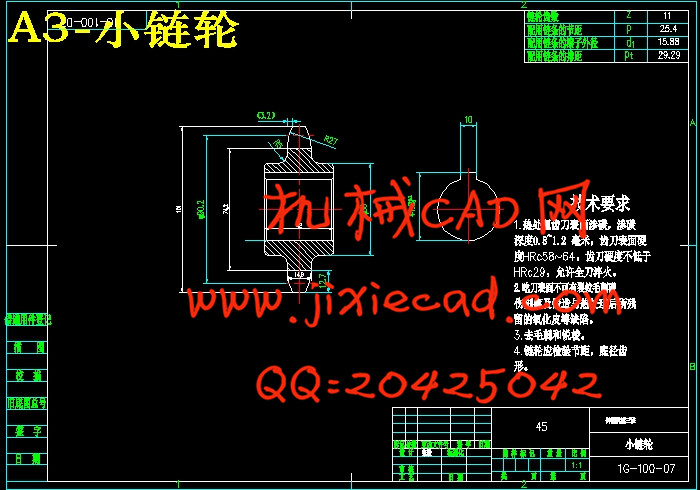

5.2 链轮设计计算……………………………………………………………… (15)

第六章 主要零部件强度计算………………………………………(16)

6.1 链传动的强度的磨损核算………………………………………………… (16)

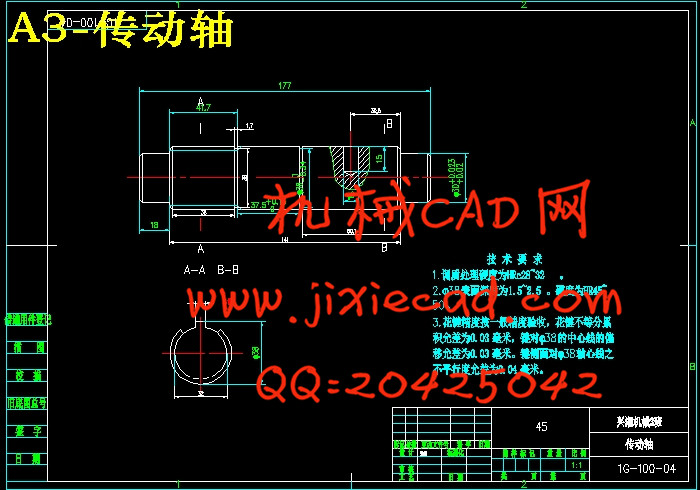

6.2 传动轴的强度计算和疲劳强度校合……………………………………… (16)

6.3 滚动轴承的计算和选择…………………………………………………… (19)

总结………………………………………………………………… (20)

参考文献…………………………………………………………… (21)

摘 要: 水旱两用旋耕机具有体积小,重量轻,性能好,操作容易,转动方便,适应性广,价格合宜,水旱两用旋耕机机动灵活,一般中小型机械厂、农机厂均可生产制造的要求。如果设计成功,本机可进行旱田旋耕、水田耙整等项作业,能弥补现有旋耕机存在功能较单一、生产效率偏低等不足之处。

我设计的是一台水旱两用旋耕机,与黄海-12(15)马力手扶拖拉机相匹配,主要用于水田耕整,也可进行旱田耕作。现有的水旱旋耕机是耕幅为0.6米的老式机型,而本课题设计的水旱旋耕机耕幅为1米。

本设计与黄海-12(15)马力手扶拖拉机相匹配,中间传动,固定联接。设计内容包括机架、传动系统、刀辊、尾轮等,要求结构简单、紧凑、重心平衡。该机可用于水田耕整地,也可进行旱田旋耕。各项性能指标应达到国家标准和农艺要求。通过对水田旋耕机驱动轮与土壤相互作用的力学特性的分析,结合水田土壤的力学性质,经过优化设计,研制水旱两用旋耕机驱动轮,使该驱动轮具有良好的动力性能。

关键词: 水田旋耕机;创新设计;驱动轮性能

Design of 1G-100-floods, droughts and dual-use Rotary machine

Abstract:The floods, droughts and dual-use Rotary machine has small size, light weight, performance, and easy to use, easy rotation. it wide adaptability and affordable. Floods, droughts and dual-use rotary machine has tiller-mobile and flexible.Small and medium-sized general machinery factory. The agriculture of factories can manufacturing requirements. If it can successful design, this machine can be floods and drought rotary,and it can rake the whole paddy field’s operations. It can to cover the existing functions of a rotary-existence’s single and low production efficiency, such as inadequate.

I design is one of the floods, droughts and dual-use rotary tiller machine, and it matchs with the Yellow Sea -12 (15) horsepower walking tractor.It not only mainlies for rotary of paddy field, but also for upland farming. The existing floods, droughts and dual-use rotary tiller machine’s rate is the 0.6-metres site in the old models, but the issue of floods, droughts and Rotary machine’s design for the 1-meter site.

The design mach with the Yellow Sea -12 (15) horsepower walking tractor . It makes the middle transmission and fixed link. The design elements include rack, drive system, knife rolls, round tail and so on. It requires frame simple and compact,and it requires the focus of balance. The aircraft not only can be used for paddy’s rotary and formation, but also for upland Rotary. Various performance indicators should meet the state standards and agronomic requirements. Through the driving wheel of paddy fields Rotary interaction with the mechanical properties of the soil analysis, combining the mechanical properties of the soil of paddy field, optimized design, development of floods, droughts and dual-use rotary tiller-driving wheel, so that the driving wheel has a good dynamic performance.

Key words: Floods, droughts and dual-use rotary machine; innovative design;the performace of driving wheel

目录

摘要

Abstract

第一章 引言…………………………………………………………(4)

第二章 总体设计……………………………………………………(5)

2.1设计的内容……………………………………………………………………(5)

2.2设计依据………………………………………………………………………(5)

2.3 设计要求 ……………………………………………………………………(5)

第三章 总体方案论证………………………………………………(7)

3.1中间链传动结构方案的设计…………………………………………………(7)

3.2主要结构和参数的设计与选择计算…………………………………………(7)

3.3.旋耕刀滚的设计……………………………………………………………(9)

3.4双油封和挡草圈的设计…………………………………………………… (11)

3.5 1G-100旋耕机主要技术规格及基本参数…………………………………(11)

第四章 总体结构的布置与设计……………………………………(12)

4.1 传动结构的设计………………………………………………………………(12)

4.2 主要结构的分析设计…………………………………………………………(12)

第五章 链传动的设计与计算………………………………………(14)

5.1 链传动的设计计算………………………………………………………… (14)

5.2 链轮设计计算……………………………………………………………… (15)

第六章 主要零部件强度计算………………………………………(16)

6.1 链传动的强度的磨损核算………………………………………………… (16)

6.2 传动轴的强度计算和疲劳强度校合……………………………………… (16)

6.3 滚动轴承的计算和选择…………………………………………………… (19)

总结………………………………………………………………… (20)

参考文献…………………………………………………………… (21)