设计简介

摘要

在当代生活中,我们生活中的每个角落充满着各式各样的机器。很多不同的领域都需要用性能不同的的起重运输机械,进行运输、分配和输送等生产作业任务,起重机械设计很广随处都能见到。例如一个大型的生产工作厂,没有现代化,有效率,安全度高的设备,是无法进行工作生产的。所以说起重机在现实生活中的作用,早已经超过了它本身的对人类的辅助作用,因此起重机已经广泛的应用在生产工艺中,是生产工作中必不可缺少的重要机械。

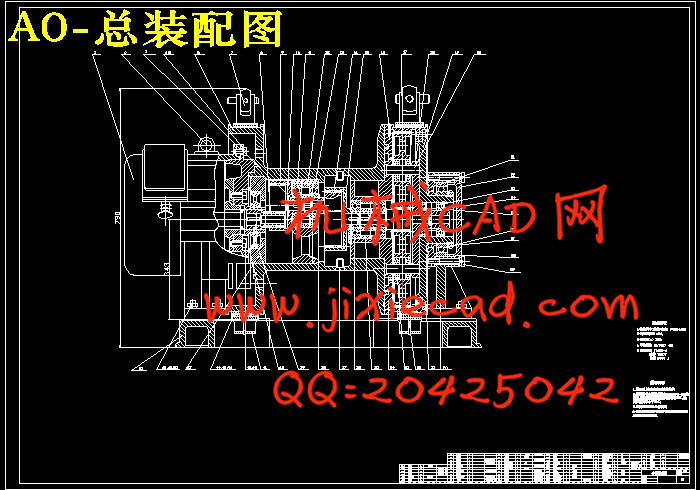

我们运用机械原理、机械制造技术和制图等知识研究设计这次的小型重物提升机。设计这种小型重物提升机是一般工作在室内。它的动力主要是电动机和通过齿轮传还有行星机传动传递动力等技术进行完成。小型重物提升机设计中关键的部分是减速器的设计要合理,设计包括:动力传动装置、执行元件、控制系统部分的设计以及对机械进行保护和密封等。

本次设计的目的主要要求解决生产中的实际问题,不仅要求掌握专业知识足够多,还要锻炼独立解决问题的能力,提高查阅设计手册的能力,了解相关尺寸的国家标准和国际标准,熟练的使用CAD/UG绘制工程图。让我们在实际工作中熟练的进行绘制,让我们的设计更具实用性,易操性。这次的设计题目还让我们更多的接触社会。了解社会的发展趋向和国内外自动化时代的现状,为自己以后的发展方向做好铺垫。运用综合所学的知识,在老师的指导下解决设计中遇到的问题,培养学生理论联系实际的能力、把握良好的设计思想和工作作风。

因此在设计小型重物提升机时,我们不仅要对机械的性能和能力保障,而且对其安全性的考虑更要谨慎考虑。在这次设计中,我认真的学习了参考文献和一些相关的机械知识并且实地进行了参考并询问老师进行问题的解决,还进行了自己操作并且了解工件的加工工艺的难易度,并上网进行了查找资料等工作在学校请教老师,因此对于小型重物提升机的设计进行了优化和改良。

关键词: 减速器; 传动系统; 执行元件;

Abstract

In the present life, various machines have been widely used in every aspect of our life..More and more areas need to use a variety of lifting transport machinery, running, distribution and transportation and other production tasks, crane design is widely everywhere can see. For example, a large production factory, there is no modern, efficient, safe equipment, is unable to work production. So that the role of crane in real life, already more than itself to human supporting role, so the crane has been widely used in the production process is production work in the indispensable important mechanical.

This design principle is the application of mechanical principle, mechanical manufacturing technology and graphics and other knowledge research design a small weight lifting machine. The design of this small weight lifting machine is generally working indoors. Its power is mainly motor and transmission through the transmission of the planetary gear transmission and other technology through the transmission of the motor and other technologies. Small weight lifting machine design and the key part of the deceleration device design to be reasonable, the design includes: power transmission system, the implementation of components, control part of the design and the mechanical lubrication and seal etc..

Drawing purpose of the design of the main requirements to solve practical problems in production, not only required to master professional knowledge enough, we must exercise independent problem solving ability, improve access to the ability to design manual, understanding related to the size of the national standards and international standards, skilled use of CAD /UG of engineering drawing. Let us in the actual work of the skilled draw, so that our design more practical, easy to operate. The design also makes us more contact with society.. Understand the social development trend and the status quo of the era of domestic and foreign automation, paving the way for their future development direction.Using the knowledge of integrated knowledge, the problem in the design is solved under the guidance of the teacher, and the ability of cultivating students' theory, the design idea and the style of work are grasped..

So when we design a small weight lifting machine, we must not only protect the mechanical performance and capacity, but also consider the safety of its security considerations.. In this design, I seriously learning the references and some related knowledge of machinery and conducted a field reference and asked the teacher problem solving, their operations and to understand the parts of the processing difficulty, and the Internet are seeking information consult the teacher at school, so for small weight lifting machine design has been optimized and improved.

Key words: Gear reducer; Drive system;Execution element;

目 录

引言.......................................................................................................... 1

第一章动力系统设计 ............................................................................ 2

1.1 设计方案的确定 ............................................................................. 2

1.1.1 设计参数.................................................................................... 2

1.1.2 设计方案的确定........................................................................ 2

1.2 电机的选择 ..................................................................................... 3

1.2.1 初选电动机类型和结构型式.................................................... 3

1.2.2 电动机的容量 .......................................................................... 4

第二章提升机传动系统设计 ................................................................ 7

2.1传动装置的传动比及动力参数计算 ................................................7

2.1.1总传动比及滚筒初定 ............................................................... 7

2.1.2传动分配各级传动比的计算 .......................................................... 7

2.2电动机轴齿轮的设计..................................................................................9

2.2.1 初步选定齿轮参数 .................................. ......................................9

2.2.2 确定轴齿轮中心距a.................................................................9

2.2.3 几何尺寸的计算 ............................................................................ 10

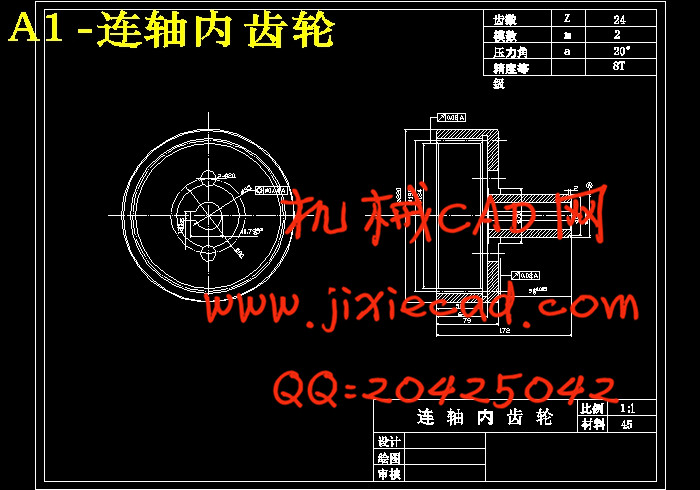

2.3 内齿轮的设计 ........................................................................................ 11

2.3.1 按齿轮齿面接触疲劳计算...................................................... 11

2.4行星齿轮的设计 ............................................................................. 12

2.4.1按齿面接触疲劳计算 .............................................................. 12

2.5 轴的结构设计 ............................................................................... 12

2.5.1 轴的结构设计原则 ................................................................ 12

2.5.2 轴承的选择 ...................................................................................... 13

2.5.3 轴II轴的设计 ........................................................................ 13

2.5.4 轴Ⅲ的设计、计算及轴承的确定 .......................................... 14

2.6 轴II轴Ⅲ的强度校核 ................................................................... 15

2.6.1 轴II的强度校核...................................................................... 15

第三章行星架的设计............................................................................ 19

第四章提升机执行机构的设计............................................................ 20

4.1卷筒的选择 .................................................................................... 20

4.1.1 卷筒的主要尺寸 .................................................................. 20

4.2吊钩的设计 ..................................................................................... 22

4.2.1吊钩的材料 .............................................................................. 22

4.2.2吊钩的构造................................................................................ 23

第五章制动器的设计............................................................................ 24

5.1.1 制动器的选用.......................................................................... 24

5.1.2 带式制动器的计算.................................................................. 24

第六章减速器的润滑和密封................................................................ 30

结 论 .................................................................................................... 31

参考文献 .............................................................................................. 32

致 谢 ................................................................................................ 33

在当代生活中,我们生活中的每个角落充满着各式各样的机器。很多不同的领域都需要用性能不同的的起重运输机械,进行运输、分配和输送等生产作业任务,起重机械设计很广随处都能见到。例如一个大型的生产工作厂,没有现代化,有效率,安全度高的设备,是无法进行工作生产的。所以说起重机在现实生活中的作用,早已经超过了它本身的对人类的辅助作用,因此起重机已经广泛的应用在生产工艺中,是生产工作中必不可缺少的重要机械。

我们运用机械原理、机械制造技术和制图等知识研究设计这次的小型重物提升机。设计这种小型重物提升机是一般工作在室内。它的动力主要是电动机和通过齿轮传还有行星机传动传递动力等技术进行完成。小型重物提升机设计中关键的部分是减速器的设计要合理,设计包括:动力传动装置、执行元件、控制系统部分的设计以及对机械进行保护和密封等。

本次设计的目的主要要求解决生产中的实际问题,不仅要求掌握专业知识足够多,还要锻炼独立解决问题的能力,提高查阅设计手册的能力,了解相关尺寸的国家标准和国际标准,熟练的使用CAD/UG绘制工程图。让我们在实际工作中熟练的进行绘制,让我们的设计更具实用性,易操性。这次的设计题目还让我们更多的接触社会。了解社会的发展趋向和国内外自动化时代的现状,为自己以后的发展方向做好铺垫。运用综合所学的知识,在老师的指导下解决设计中遇到的问题,培养学生理论联系实际的能力、把握良好的设计思想和工作作风。

因此在设计小型重物提升机时,我们不仅要对机械的性能和能力保障,而且对其安全性的考虑更要谨慎考虑。在这次设计中,我认真的学习了参考文献和一些相关的机械知识并且实地进行了参考并询问老师进行问题的解决,还进行了自己操作并且了解工件的加工工艺的难易度,并上网进行了查找资料等工作在学校请教老师,因此对于小型重物提升机的设计进行了优化和改良。

关键词: 减速器; 传动系统; 执行元件;

Abstract

In the present life, various machines have been widely used in every aspect of our life..More and more areas need to use a variety of lifting transport machinery, running, distribution and transportation and other production tasks, crane design is widely everywhere can see. For example, a large production factory, there is no modern, efficient, safe equipment, is unable to work production. So that the role of crane in real life, already more than itself to human supporting role, so the crane has been widely used in the production process is production work in the indispensable important mechanical.

This design principle is the application of mechanical principle, mechanical manufacturing technology and graphics and other knowledge research design a small weight lifting machine. The design of this small weight lifting machine is generally working indoors. Its power is mainly motor and transmission through the transmission of the planetary gear transmission and other technology through the transmission of the motor and other technologies. Small weight lifting machine design and the key part of the deceleration device design to be reasonable, the design includes: power transmission system, the implementation of components, control part of the design and the mechanical lubrication and seal etc..

Drawing purpose of the design of the main requirements to solve practical problems in production, not only required to master professional knowledge enough, we must exercise independent problem solving ability, improve access to the ability to design manual, understanding related to the size of the national standards and international standards, skilled use of CAD /UG of engineering drawing. Let us in the actual work of the skilled draw, so that our design more practical, easy to operate. The design also makes us more contact with society.. Understand the social development trend and the status quo of the era of domestic and foreign automation, paving the way for their future development direction.Using the knowledge of integrated knowledge, the problem in the design is solved under the guidance of the teacher, and the ability of cultivating students' theory, the design idea and the style of work are grasped..

So when we design a small weight lifting machine, we must not only protect the mechanical performance and capacity, but also consider the safety of its security considerations.. In this design, I seriously learning the references and some related knowledge of machinery and conducted a field reference and asked the teacher problem solving, their operations and to understand the parts of the processing difficulty, and the Internet are seeking information consult the teacher at school, so for small weight lifting machine design has been optimized and improved.

Key words: Gear reducer; Drive system;Execution element;

目 录

引言.......................................................................................................... 1

第一章动力系统设计 ............................................................................ 2

1.1 设计方案的确定 ............................................................................. 2

1.1.1 设计参数.................................................................................... 2

1.1.2 设计方案的确定........................................................................ 2

1.2 电机的选择 ..................................................................................... 3

1.2.1 初选电动机类型和结构型式.................................................... 3

1.2.2 电动机的容量 .......................................................................... 4

第二章提升机传动系统设计 ................................................................ 7

2.1传动装置的传动比及动力参数计算 ................................................7

2.1.1总传动比及滚筒初定 ............................................................... 7

2.1.2传动分配各级传动比的计算 .......................................................... 7

2.2电动机轴齿轮的设计..................................................................................9

2.2.1 初步选定齿轮参数 .................................. ......................................9

2.2.2 确定轴齿轮中心距a.................................................................9

2.2.3 几何尺寸的计算 ............................................................................ 10

2.3 内齿轮的设计 ........................................................................................ 11

2.3.1 按齿轮齿面接触疲劳计算...................................................... 11

2.4行星齿轮的设计 ............................................................................. 12

2.4.1按齿面接触疲劳计算 .............................................................. 12

2.5 轴的结构设计 ............................................................................... 12

2.5.1 轴的结构设计原则 ................................................................ 12

2.5.2 轴承的选择 ...................................................................................... 13

2.5.3 轴II轴的设计 ........................................................................ 13

2.5.4 轴Ⅲ的设计、计算及轴承的确定 .......................................... 14

2.6 轴II轴Ⅲ的强度校核 ................................................................... 15

2.6.1 轴II的强度校核...................................................................... 15

第三章行星架的设计............................................................................ 19

第四章提升机执行机构的设计............................................................ 20

4.1卷筒的选择 .................................................................................... 20

4.1.1 卷筒的主要尺寸 .................................................................. 20

4.2吊钩的设计 ..................................................................................... 22

4.2.1吊钩的材料 .............................................................................. 22

4.2.2吊钩的构造................................................................................ 23

第五章制动器的设计............................................................................ 24

5.1.1 制动器的选用.......................................................................... 24

5.1.2 带式制动器的计算.................................................................. 24

第六章减速器的润滑和密封................................................................ 30

结 论 .................................................................................................... 31

参考文献 .............................................................................................. 32

致 谢 ................................................................................................ 33