设计简介

摘要

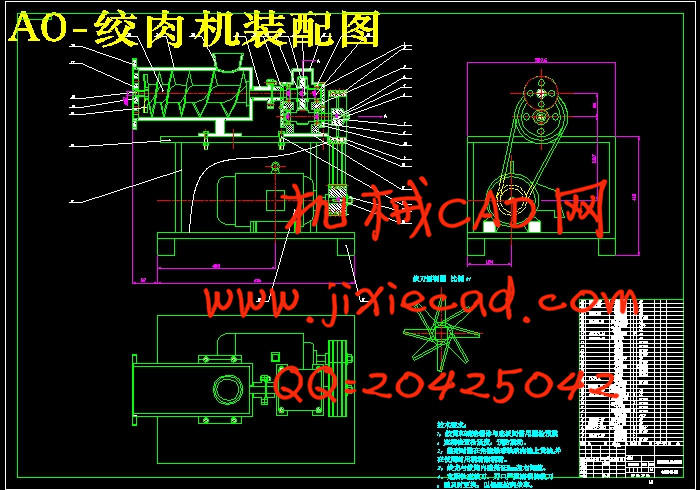

绞肉机是肉类加工企业在生产过程中将原料肉按不同工艺要求加工规格不等的颗粒状肉馅,广泛适用于各种香肠、火腿肠、午餐肉、丸子、咸味香精、宠物食品和其他肉制品等行业。本文论述了绞肉机的结构、工作原理、主要技术参数、传动系统、典型零件的结构设计及生产能力分析。希望对本次设计的探索和研究能设计出实用经济的家用绞肉机,更好的方便人民的生活食品工业的现代化水平,在很大程度上依赖于食品机械的发展及其现代化水,离开现代仪器和设备,现代食品工业就无从谈起。食品工业的发展是设备和工艺共同发展的结果,应使设备和工艺达到最佳配合,以设备革新和创新促进工艺的改进和发展,以工艺的发展进一部促进设备的发展和完善。两者互相促进、互相完善,是使整个食品工业向现代化迈进的必要条件。

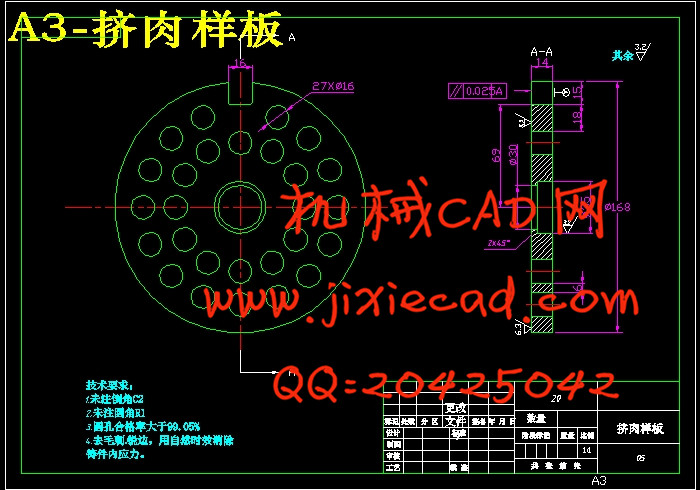

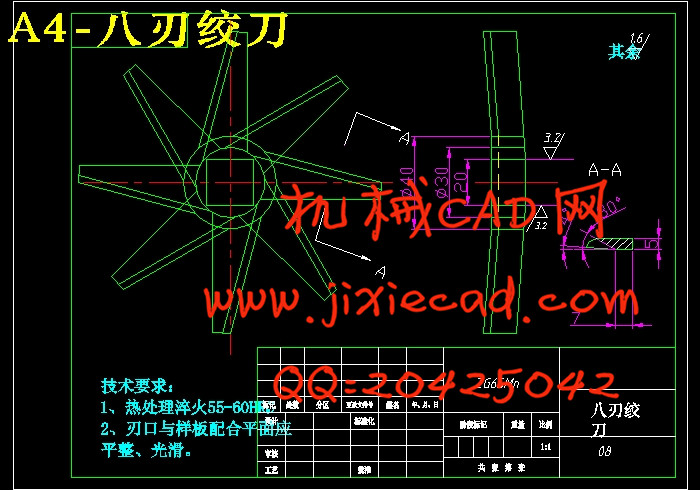

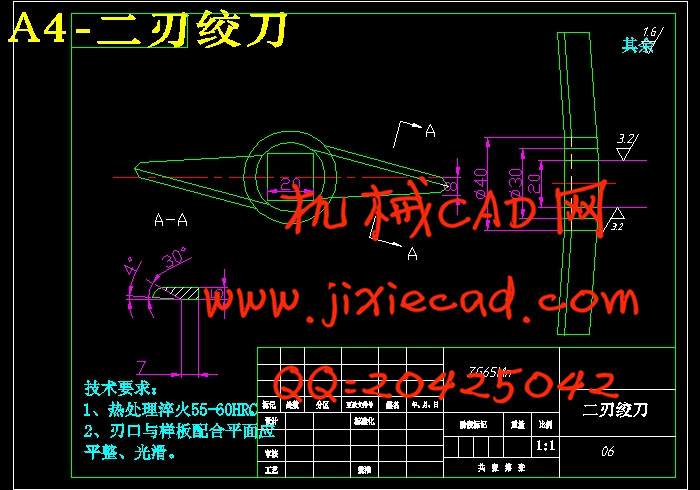

关键词:绞肉机;挤肉样板;绞刀;绞龙;螺旋供料器;齿轮强度

Abstract

Is meat processing enterprise in stage production of raw meat will according to different process request processing specifications vary granular meat, widely used in all kinds of sausage, ham bowel, lunch meat ball, salty, essence, pet food and other meat products, etc.Many practical machines in our life are from mechanical design, this paper elaborates on the meat chopper’s structure,operating principlemain ,technical parameter, transmission system andstructural design and production capacity analysis of typical parts are mannyintroduced.It is hoped that a practical and economical household meat chopper could be designed according to the author’s exploration, which would be convenient for the life of people.

instruments and equipment the modern food industry cannot survive. The food industry is the development of the equipment and the result of the development of common technology should make the equipment and technology reach the best with equipment and innovation to promote the innovation process improvement and development, in order to promote the development of the technology into a equipment of development and perfection. Both promote each other, mutual perfect, is to make the whole food industry on the necessary conditions to modernization.

Key words: meat chopper;crowded meat model;reamer;stranding cage;screw feeder;gear strength

电动绞肉机的设计

目录

摘要 I

Abstract II

1绪 论 1

1结 构 及 工 作 原 理 2

1.1绞肉机的结构 2

1.2绞肉机的工作原理 2

3绞龙的设计 3

3.1绞龙的设计 3

3.1.1绞龙的材料 4

3.1.2绞龙直径 4

3.1.3绞龙的转速 4

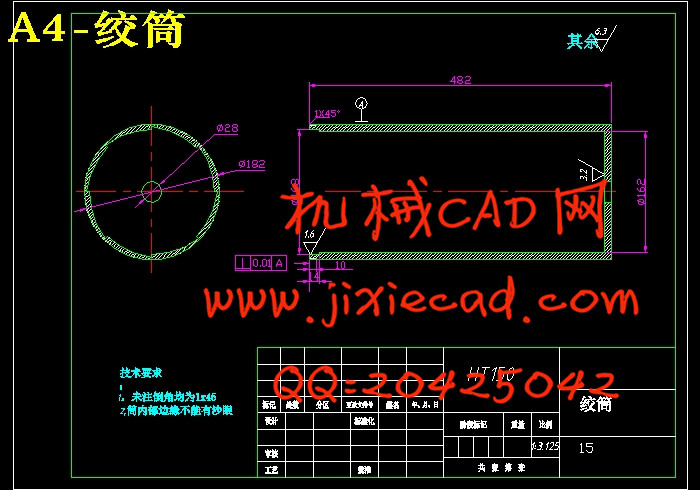

3.2绞筒的设计 4

4 传动系统的设计 4

4.1电机的选择 5

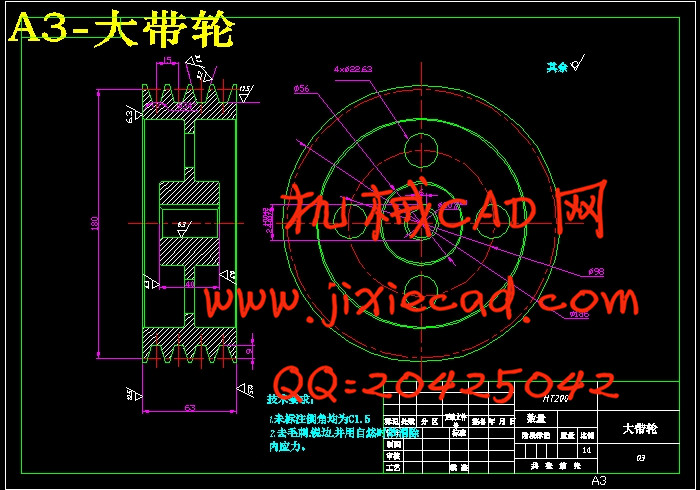

4.2 带轮的设计 5

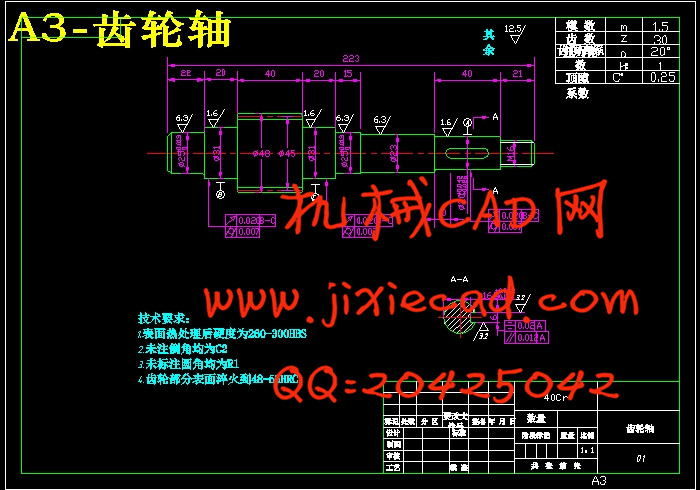

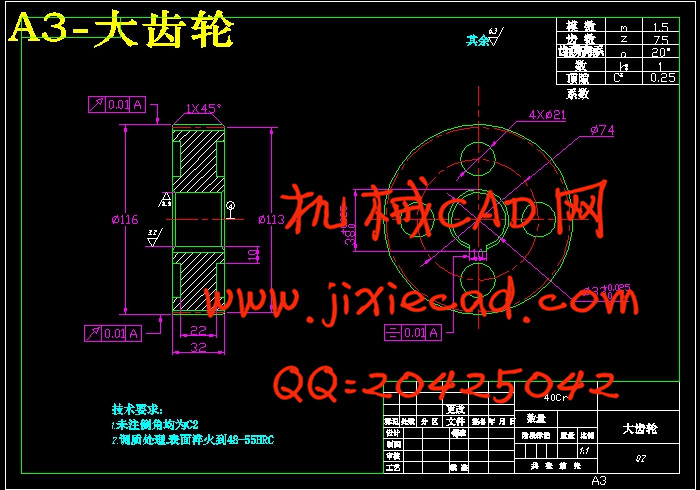

4.3齿轮传动的设计计算 8

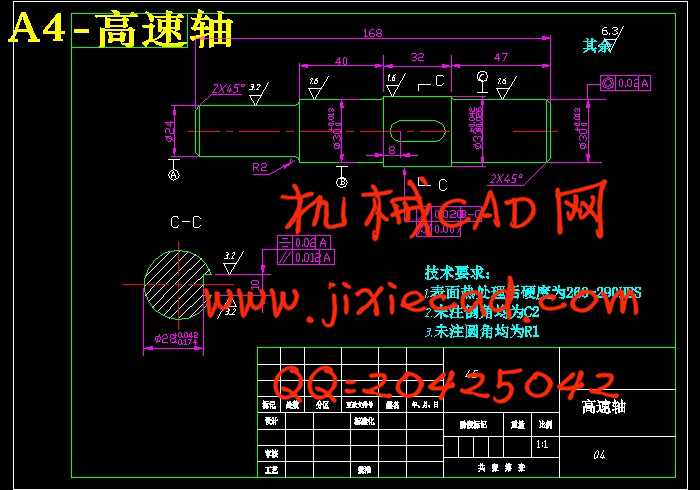

4.4齿轮轴的设计与校核 11

4.4.1各轴的转速计算 12

4.4.2各轴输入功率计算 12

4.4.3各轴输入扭矩计算 12

4.4.4 按弯扭合成强度校核轴径 12

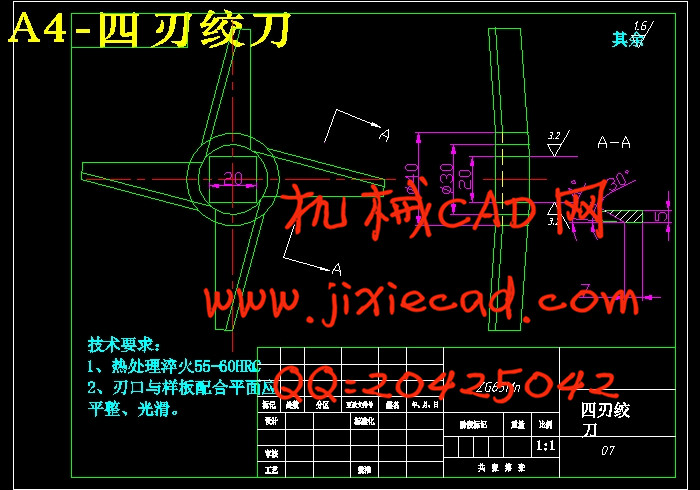

5绞 刀 设 计 13

5.1绞刀的设计 13

5.1.1刀刃的起讫位置 14

5.1.2刀刃的前角 14

5.1.3刀刃的后角 14

5.1.4刀刃的刃倾角 15

5.1.5刀片的结构 15

6生产能力分析 16

6.1绞刀的切割能力 16

6.2 绞肉机的生产能力G 16

6.3功率消耗N 16

7绞肉机的使用与日常维护简介 16

8设计小结 18

参考文献 19