设计简介

0.75型卷扬机设计

摘 要

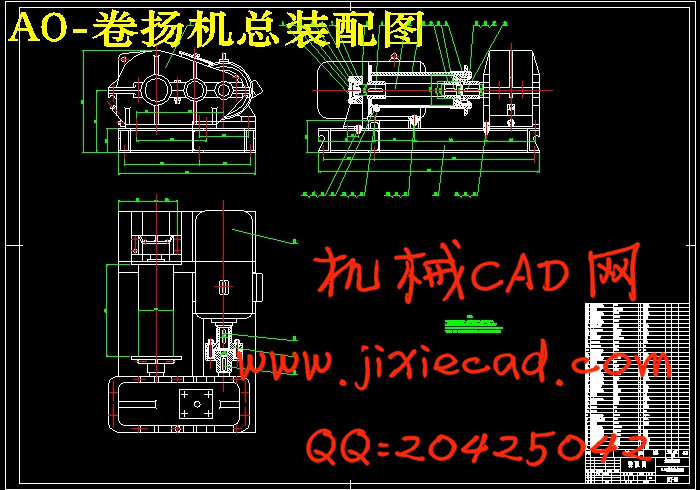

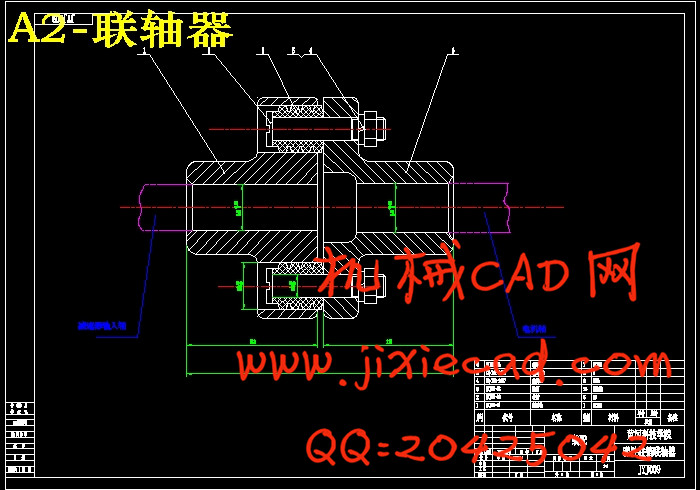

卷扬机又称绞车。是起重垂直运输机械的重要组成部分,配合井架、桅杆、滑轮组等辅助设备,用来提升物料、安装设备等作业,由人力或机械动力驱动卷筒、卷绕绳索来完成牵引工作的装置。垂直提升、水平或倾斜曳引重物的简单起重机械。分手动和电动两种。现在以电动卷扬机为主。本设计采用了新型的制动电机,节省了制动器,使得结构更加紧凑,提高了安全可靠系数,这也是机械行业的一个发展趋势。其主要结构组成还有,减速器、联轴器、卷筒。

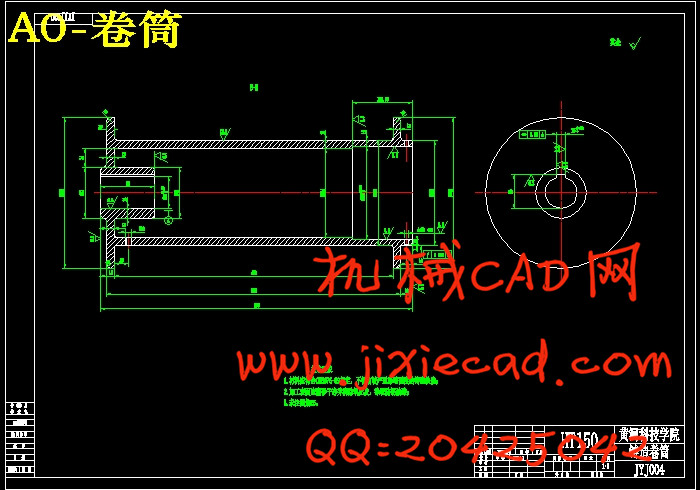

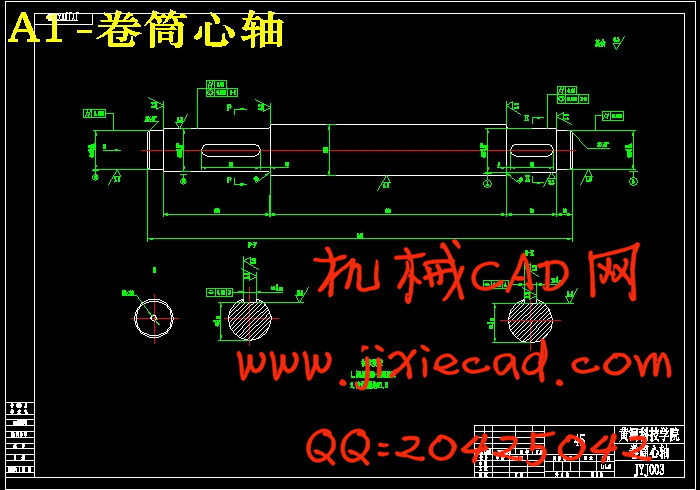

本次设计的步骤是从钢丝绳开始入手,然后依次对卷扬机的卷筒、卷筒心轴、制动电动机、减速器的设计计算选取。其中卷筒、卷筒轴、减速器的设计最为主要,本设计重点做了介绍,其余部分有得只是略作分析。

本次设计的卷筒机由于它结构简单、搬运安装灵活、操作方便、维护保养简单、对作业环境适应能力强等特点,可以应用于冶金起重、建筑、水利作业等方面。提升重物是卷扬机的一种主要功能,各类卷扬机的设计都是根据这一要求为依据的。

关键词:卷扬机,制动电机,卷筒,卷筒轴,减速器

The design of 0.75construction winches

Author: Li Lei

Tutor: Kang Hongwei

Abstract

Also known the hoist another name is winch. Vertical lifting transport machinery is an important component of the tie in with the derrick, mast, pulley blocks, and auxiliary equipment, used to enhance the materials, installation of equipment operations, from human or mechanical power-driven drum, winding traction rope to complete the installation work. Two types of the hoist are manual and electric two kinds. and Now to the main electric winch. The design of the 5-ton electric hoist motor contions electromotor 、coupling、arrester、retarder、drum、boom sheave 、a system of pulleys set、hook, etc.

This design of hoist is start from the wire rope, and next then turn on the winch drum, drum spindle, motor, gear reducer, speed reducer shaft, brakes, couplings and pulley drum machine-oriented design and selection. On drum, drum shaft, drum hub, most major reducer design, the design are focus introduced, and the rest is just a little something for analysis.

The design of the drum machine because of its simple structure, handling the installation of a flexible, convenient operation, simple maintenance, and operating environment features such as adaptability, can be applied to lifting metallurgical, construction, operations and other water conservancy, but the design mainly applied to the drum machine for 5-ton overhead crane hoisting mechanism. Heavy winch upgrade is one of the main functions of the design of various types of winches are based on based on this request.

Key words: hoist,brake motor, drum,drum shaft,retarder

摘 要

卷扬机又称绞车。是起重垂直运输机械的重要组成部分,配合井架、桅杆、滑轮组等辅助设备,用来提升物料、安装设备等作业,由人力或机械动力驱动卷筒、卷绕绳索来完成牵引工作的装置。垂直提升、水平或倾斜曳引重物的简单起重机械。分手动和电动两种。现在以电动卷扬机为主。本设计采用了新型的制动电机,节省了制动器,使得结构更加紧凑,提高了安全可靠系数,这也是机械行业的一个发展趋势。其主要结构组成还有,减速器、联轴器、卷筒。

本次设计的步骤是从钢丝绳开始入手,然后依次对卷扬机的卷筒、卷筒心轴、制动电动机、减速器的设计计算选取。其中卷筒、卷筒轴、减速器的设计最为主要,本设计重点做了介绍,其余部分有得只是略作分析。

本次设计的卷筒机由于它结构简单、搬运安装灵活、操作方便、维护保养简单、对作业环境适应能力强等特点,可以应用于冶金起重、建筑、水利作业等方面。提升重物是卷扬机的一种主要功能,各类卷扬机的设计都是根据这一要求为依据的。

关键词:卷扬机,制动电机,卷筒,卷筒轴,减速器

The design of 0.75construction winches

Author: Li Lei

Tutor: Kang Hongwei

Abstract

Also known the hoist another name is winch. Vertical lifting transport machinery is an important component of the tie in with the derrick, mast, pulley blocks, and auxiliary equipment, used to enhance the materials, installation of equipment operations, from human or mechanical power-driven drum, winding traction rope to complete the installation work. Two types of the hoist are manual and electric two kinds. and Now to the main electric winch. The design of the 5-ton electric hoist motor contions electromotor 、coupling、arrester、retarder、drum、boom sheave 、a system of pulleys set、hook, etc.

This design of hoist is start from the wire rope, and next then turn on the winch drum, drum spindle, motor, gear reducer, speed reducer shaft, brakes, couplings and pulley drum machine-oriented design and selection. On drum, drum shaft, drum hub, most major reducer design, the design are focus introduced, and the rest is just a little something for analysis.

The design of the drum machine because of its simple structure, handling the installation of a flexible, convenient operation, simple maintenance, and operating environment features such as adaptability, can be applied to lifting metallurgical, construction, operations and other water conservancy, but the design mainly applied to the drum machine for 5-ton overhead crane hoisting mechanism. Heavy winch upgrade is one of the main functions of the design of various types of winches are based on based on this request.

Key words: hoist,brake motor, drum,drum shaft,retarder

目录

1绪论 1

2 卷扬机的整体概述 3

2.1电动卷扬机的基本结构 3

2.1.1电控卷扬机 3

2.1.2带有电磁铁制动器的卷扬机 3

2.1.3采用锥形转子电动机的卷扬机 4

2.1.4溜放型卷扬机 5

2.2卷扬机工作级别与类别 5

3 零部件的计算 7

3.1 钢丝绳的选取 7

3.1.1钢丝绳的种类和构造 7

3.1.2钢丝绳直径的选择 7

3.1.3钢丝绳的使用 9

3.2 卷筒的结构设计及尺寸确定 10

3.2.1卷筒的分类 10

3.2.2卷筒绳槽尺寸的确定 10

3.2.3卷筒的设计 10

3.2.4卷筒的强度校核 12

3.3卷筒轴的设计计算 13

3.4轴承的选择 16

3.5电动机的选择 16

3.5.1选择电动机应该综合考虑的问题 17

3.5.2电动机选择顺序 17

3.5.3电动机类型的选择 18

3.5.4电动机功率的选择 19

3.5.5电动机转速的选择 19

3.5.6电动机功率的计算 20

3.6 减速器的选择 21

3.7 联轴器的选择 22

4 卷扬机的安装使用及安全操作规程 23

4.1 卷扬机的安装及安装调试 23

4.1.1卷扬机的安装 23

4.1.2卷扬机调试 23

4.2卷扬机使用与操作 23

4.3电气安全保护 24

总结 25

致谢 26

参考文献 27