设计简介

摘 要

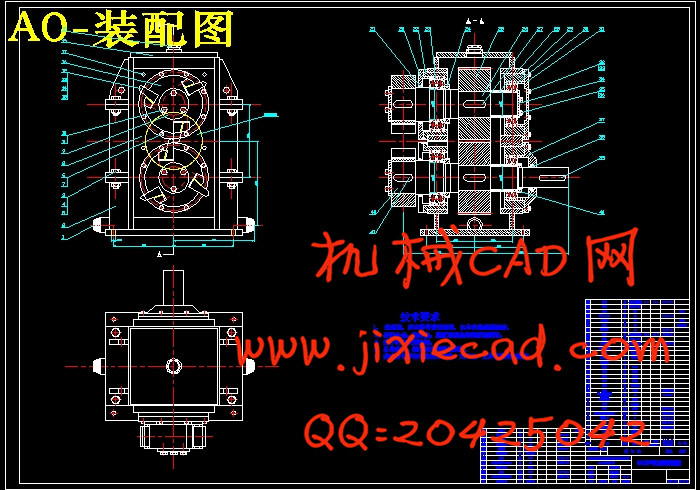

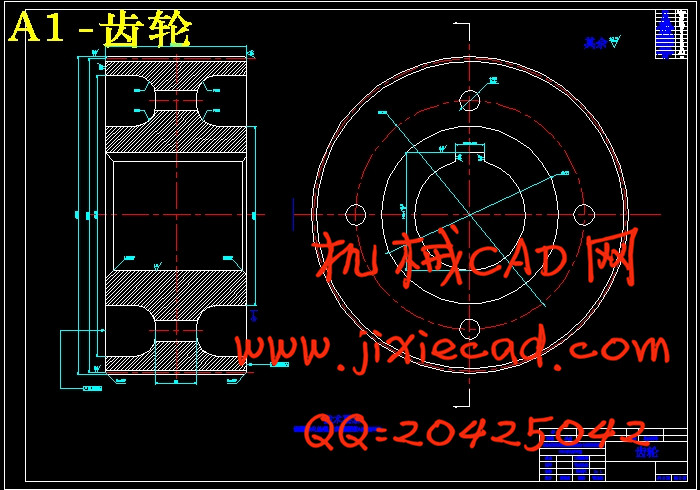

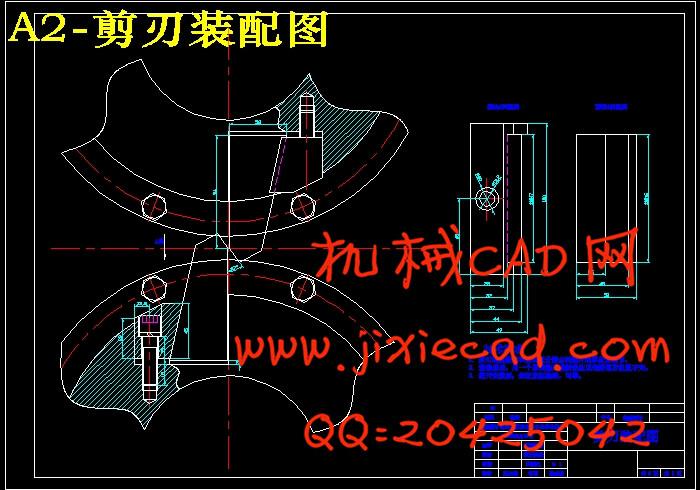

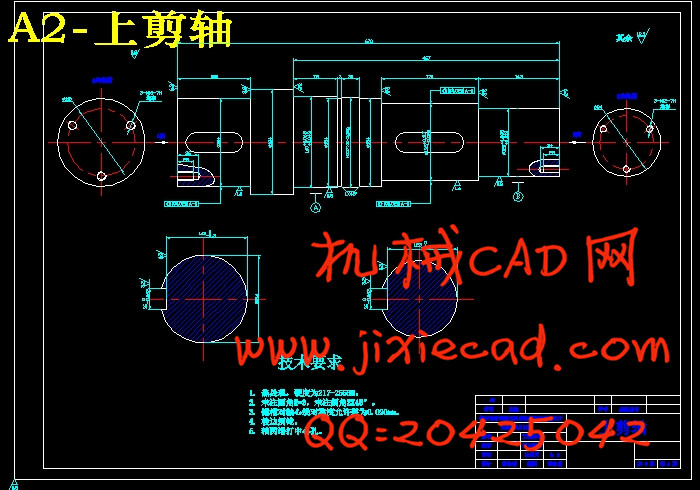

线材生产中的飞剪机是用来切头、切尾、以及当出现事故时切取定尺的。飞剪机有许多类型,论文中的380双滚筒式碎断剪,是应用在高速线材生产中的一中。它采用单机驱动,通过齿轮和联轴器,带动传动轴,然后由输出轴上的剪刃切断轧件。本文做了以下工作:1.选择和确定了传动方案。2.选择并校核了电动机。3.设计了传动轴和齿轮,并校核了它们的强度。4.选择了与之配套的润滑系统和维修制度。

关键字:圆盘飞剪、单电动机传动、开式机架、最大剪切力、弯扭合成应力。

线材生产中的飞剪机是用来切头、切尾、以及当出现事故时切取定尺的。飞剪机有许多类型,论文中的380双滚筒式碎断剪,是应用在高速线材生产中的一中。它采用单机驱动,通过齿轮和联轴器,带动传动轴,然后由输出轴上的剪刃切断轧件。本文做了以下工作:1.选择和确定了传动方案。2.选择并校核了电动机。3.设计了传动轴和齿轮,并校核了它们的强度。4.选择了与之配套的润滑系统和维修制度。

关键字:圆盘飞剪、单电动机传动、开式机架、最大剪切力、弯扭合成应力。

Abstract

Flying shear is used to cut head and end and design length as well as accident on wire rod producing. Flying shear has many kinds types. The 380 breaking shear designed in this paper is one of them. It adapts one electrical machine to drive.The electrical machine passes though gear and clutch, to drive the shafts and cut down the wire rod. The following work has been completed in this paper. One. Selecting and defining design scheme. Two. selecting and checking electrical machine. Three. Designing and checking principal shafts and gears. Four. Selecting suitable lubricate system and maintain scheme.

Key words: disk fly shear, single electromotor transmission, opening type machine rack, most cut power, crankle compound stress.

Flying shear is used to cut head and end and design length as well as accident on wire rod producing. Flying shear has many kinds types. The 380 breaking shear designed in this paper is one of them. It adapts one electrical machine to drive.The electrical machine passes though gear and clutch, to drive the shafts and cut down the wire rod. The following work has been completed in this paper. One. Selecting and defining design scheme. Two. selecting and checking electrical machine. Three. Designing and checking principal shafts and gears. Four. Selecting suitable lubricate system and maintain scheme.

Key words: disk fly shear, single electromotor transmission, opening type machine rack, most cut power, crankle compound stress.

目 录

摘 要 I

Abstract II

第一章 引 言 3

1.1 线材的概论 1

1.1.1 线材中碎断剪的工作原理 1

1.1.2 线材的概念及用途 1

1.1.3 线材轧机的工艺特点 4

1.1.4 线材轧机的发展前景 5

1.2 飞剪机的概况 6

1.2.1线材生产中飞剪机的作用特点 6

1.2.2飞剪机的类型 7

1.2.3飞剪机发展状况…………………………………………………………….....9

第二章 主要零部件设计 9

2.1 结构设计 9

2.2 剪切力、剪切力矩的计算 12

2.3 主电机的计算以及类型选择 15

2.4 主要零件的设计、选择及校核 16

2.4.1 转速与扭距的计算 16

2.4.2 齿轮的设计 17

2.4.3 轴的设计 23

2.4.4 轴承及键的选择与校核…………………………………………………….40

2.4.5 连轴器的选用与校核 43

2.4.6 刀架的设计及校核 43

2.4.7 电动机的校核 47

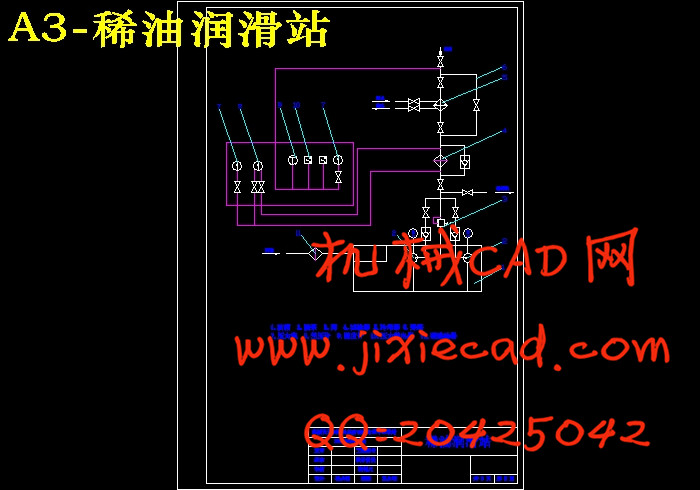

2.5 碎断剪的润滑与维修 49

2.5.1 碎断剪的润滑 49

2.5.2 碎断剪的维修 50

结束语 51

参考文献 52