设计简介

1700冷轧机组卷取机设计

摘要

卷取机是轧钢成卷生产不可少的设备。保证卷取机顺利工作对提高轧机生产率有很重要意义。冷轧机组中,卷取机用于卷取带钢成钢卷。采用恒张力轧制,可以提高带钢质量。 这次设计是1700冷轧机组卷取机设计,其用于二机架冷轧机组中。首先,选择卷取机的设计方案,并对设计方案进行评述。由于冷带钢卷取张力大,采用四棱锥卷筒结构。用液压缸移动斜楔进行胀缩。将四棱锥体单独加工装在卷筒轴上,这样改进,加工方便。当锥体磨损后可以单独更换。这样,可以降低设备维修费用。另外,四个扇形块边采用搭接技术,防止卷筒胀开后出现空隙,减少钢卷局部压扁,提高钢卷质量。去掉钳口,采用助卷器卡紧带钢头部,方便卸卷。 这次设计,进行主电机容量的计算和选择。对斜楔进行受力分析。计算带钢卷取过程中对卷筒的压力并计算卷取轴弯曲强度,对传动齿轮进行设计计算。对支承轴承进行选择和校核。采用合理的润滑方案、润滑方法和控制技术,使卷取机技术先进,经济合理。强度足够,有广泛的使用价值,可用于酸洗、热处理、镀锌和镀锌机组中。

关键词: 卷取机,斜楔胀缩,助卷

1700 cold rolling unit coiler design

Abstract

The coiler is rolls steel the volume production not to be possible the few equipment. Guaranteed the coiler smooth work to enhances the rolling mill productivity to have the very vital significance. In the cold rolling unit, the coiler uses in the volume taking hoop Cheng Gangjuan. Uses the permanent tensity rolling, may improve the hoop quality.

The lap machine design of 1700 cold calendar units to used for two expansions of cold calendar units. First of all, choice the design project of lap machine, and carry on a comment towards it. In that the cold strips of lap tensile force is big, adopt four rib awls roll structures. Using the hydraulic cylinder to move the oblique wedge to expansion and contracting. It is convenience that processing four rib awls alone and setting on the roll. When the awls wear away, we can replace it alone. So it will reduce the maintenance costs of equipments. In addition, four fan-shaped piece side adoptions taking the lap laying lap work technique for avoiding appearing interstice after rolling expansion, reducing the steel roll parts to staving and enhancing quality of strips. To throw away the pliers , taking auxiliary roll machine to take the strips tightly for unloads strips conveniently.

The design of task is that calculation and choice of the main electrical engineering capacity. To analyze force of the oblique wedge. The calculation that the roll stress of taking strips and flection intensity of the roll shaft, and transmission gears. Choice and checking bearings. Taking reasonable project and method of lubricating ,and control technique, in order to the lap machine has advanced technique, reasonable economy ,the intensity is enough and extensive using value. It can be used for sour wash, hot processing, galvanization and galvanization units.

Keyword: lap machine, the oblique wedge expansion and contracting, auxiliary roll

目录

1 绪论 1

1.1选题的背景和目的 1

1.2带钢卷取机国内外发展 1

1.3冷带钢卷取机研究内容和方法 2

1.3.1冷轧机组平面布置图,卷取机的作用 2

1.3.2冷带钢卷取机的类型和特点 3

1.3.3带钢卷取机研究内容和方法 3

2 方案的选择与分析 5

3 卷筒的设计计算 6

3.1卷筒当量半径的确定 6

3.2卷筒径向压力的计算 6

3.3卷筒的强度条件 8

3.4卷取张力的计算 8

3.5卷筒胀缩机构受力分析 8

3.5.1卷取工作时收缩时的受力分析 9

3.5.2卸卷时卷筒缩径的受力分析 11

3.6轴向胀缩液压缸行程计算 11

3.7胀缩缸直径的计算 13

4 卷筒传动设计 14

4.1电机的额定转速与传动比 14

4.2激磁调整范围与最大卷径比 14

4.3卷筒电机功率计算 15

5 减速器的设计计算 17

5.1传动装置的运动和动力参数 17

5.2齿轮的设计计算 17

5.2.1选定齿轮类型、精度等级、材料及齿数 17

5.2.2按齿面接触强度设计 17

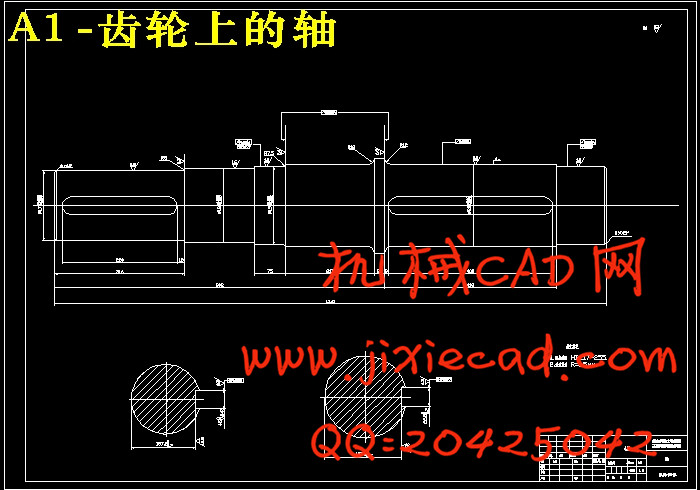

5.3心轴的校核 23

5.3.1作出心轴的计算简图 23

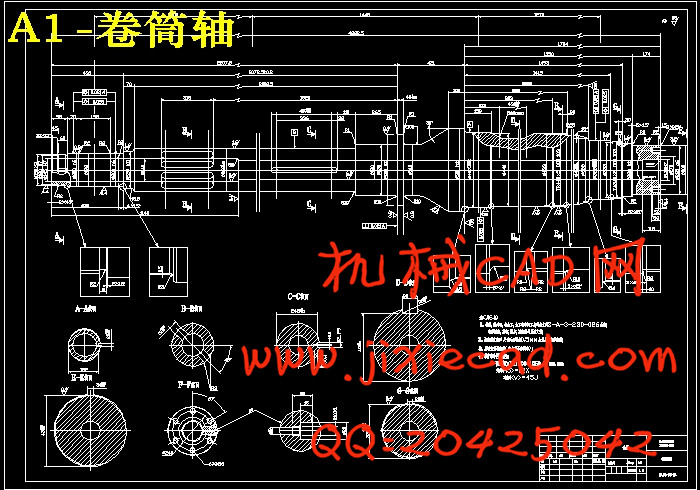

5.4轴的计算简图 28

5.4.1作出轴的计算简图 28

6 轴承计算 32

6.1轴承的寿命计算 32

7 润滑方法的选择 34

7.1减速机润滑方法及润滑油的选择 34

7.2卷取机的润滑 34

8 试车方法和对控制的要求 35

8.1试车要求 35

8.2对控制系统的要求 35

9 设备可靠性与经济评价 36

9.1机械设备的有效度 36

9.2投资回收期 36

结论 38

致谢 39

参考文献 40

附录 41

外文翻译 41

原文

摘要

卷取机是轧钢成卷生产不可少的设备。保证卷取机顺利工作对提高轧机生产率有很重要意义。冷轧机组中,卷取机用于卷取带钢成钢卷。采用恒张力轧制,可以提高带钢质量。 这次设计是1700冷轧机组卷取机设计,其用于二机架冷轧机组中。首先,选择卷取机的设计方案,并对设计方案进行评述。由于冷带钢卷取张力大,采用四棱锥卷筒结构。用液压缸移动斜楔进行胀缩。将四棱锥体单独加工装在卷筒轴上,这样改进,加工方便。当锥体磨损后可以单独更换。这样,可以降低设备维修费用。另外,四个扇形块边采用搭接技术,防止卷筒胀开后出现空隙,减少钢卷局部压扁,提高钢卷质量。去掉钳口,采用助卷器卡紧带钢头部,方便卸卷。 这次设计,进行主电机容量的计算和选择。对斜楔进行受力分析。计算带钢卷取过程中对卷筒的压力并计算卷取轴弯曲强度,对传动齿轮进行设计计算。对支承轴承进行选择和校核。采用合理的润滑方案、润滑方法和控制技术,使卷取机技术先进,经济合理。强度足够,有广泛的使用价值,可用于酸洗、热处理、镀锌和镀锌机组中。

关键词: 卷取机,斜楔胀缩,助卷

1700 cold rolling unit coiler design

Abstract

The coiler is rolls steel the volume production not to be possible the few equipment. Guaranteed the coiler smooth work to enhances the rolling mill productivity to have the very vital significance. In the cold rolling unit, the coiler uses in the volume taking hoop Cheng Gangjuan. Uses the permanent tensity rolling, may improve the hoop quality.

The lap machine design of 1700 cold calendar units to used for two expansions of cold calendar units. First of all, choice the design project of lap machine, and carry on a comment towards it. In that the cold strips of lap tensile force is big, adopt four rib awls roll structures. Using the hydraulic cylinder to move the oblique wedge to expansion and contracting. It is convenience that processing four rib awls alone and setting on the roll. When the awls wear away, we can replace it alone. So it will reduce the maintenance costs of equipments. In addition, four fan-shaped piece side adoptions taking the lap laying lap work technique for avoiding appearing interstice after rolling expansion, reducing the steel roll parts to staving and enhancing quality of strips. To throw away the pliers , taking auxiliary roll machine to take the strips tightly for unloads strips conveniently.

The design of task is that calculation and choice of the main electrical engineering capacity. To analyze force of the oblique wedge. The calculation that the roll stress of taking strips and flection intensity of the roll shaft, and transmission gears. Choice and checking bearings. Taking reasonable project and method of lubricating ,and control technique, in order to the lap machine has advanced technique, reasonable economy ,the intensity is enough and extensive using value. It can be used for sour wash, hot processing, galvanization and galvanization units.

Keyword: lap machine, the oblique wedge expansion and contracting, auxiliary roll

目录

1 绪论 1

1.1选题的背景和目的 1

1.2带钢卷取机国内外发展 1

1.3冷带钢卷取机研究内容和方法 2

1.3.1冷轧机组平面布置图,卷取机的作用 2

1.3.2冷带钢卷取机的类型和特点 3

1.3.3带钢卷取机研究内容和方法 3

2 方案的选择与分析 5

3 卷筒的设计计算 6

3.1卷筒当量半径的确定 6

3.2卷筒径向压力的计算 6

3.3卷筒的强度条件 8

3.4卷取张力的计算 8

3.5卷筒胀缩机构受力分析 8

3.5.1卷取工作时收缩时的受力分析 9

3.5.2卸卷时卷筒缩径的受力分析 11

3.6轴向胀缩液压缸行程计算 11

3.7胀缩缸直径的计算 13

4 卷筒传动设计 14

4.1电机的额定转速与传动比 14

4.2激磁调整范围与最大卷径比 14

4.3卷筒电机功率计算 15

5 减速器的设计计算 17

5.1传动装置的运动和动力参数 17

5.2齿轮的设计计算 17

5.2.1选定齿轮类型、精度等级、材料及齿数 17

5.2.2按齿面接触强度设计 17

5.3心轴的校核 23

5.3.1作出心轴的计算简图 23

5.4轴的计算简图 28

5.4.1作出轴的计算简图 28

6 轴承计算 32

6.1轴承的寿命计算 32

7 润滑方法的选择 34

7.1减速机润滑方法及润滑油的选择 34

7.2卷取机的润滑 34

8 试车方法和对控制的要求 35

8.1试车要求 35

8.2对控制系统的要求 35

9 设备可靠性与经济评价 36

9.1机械设备的有效度 36

9.2投资回收期 36

结论 38

致谢 39

参考文献 40

附录 41

外文翻译 41

原文