设计简介

摘 要

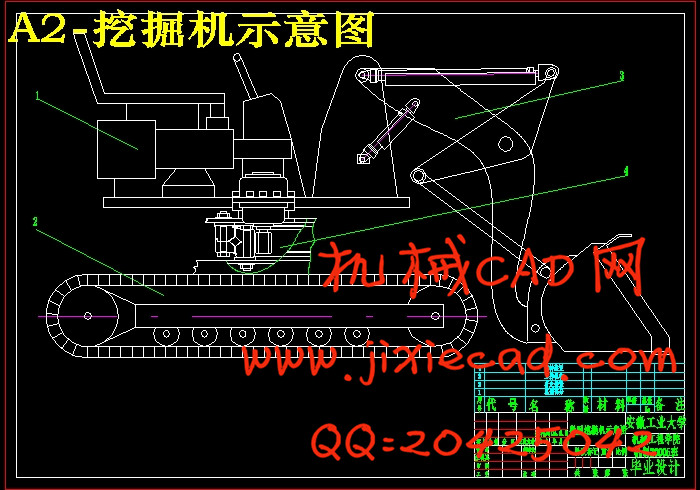

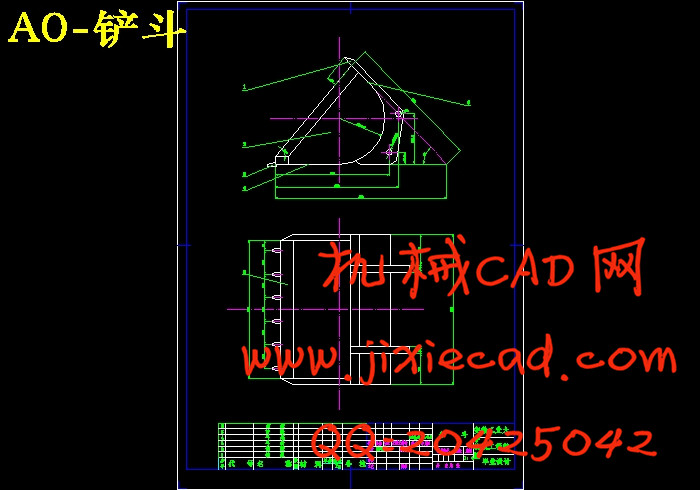

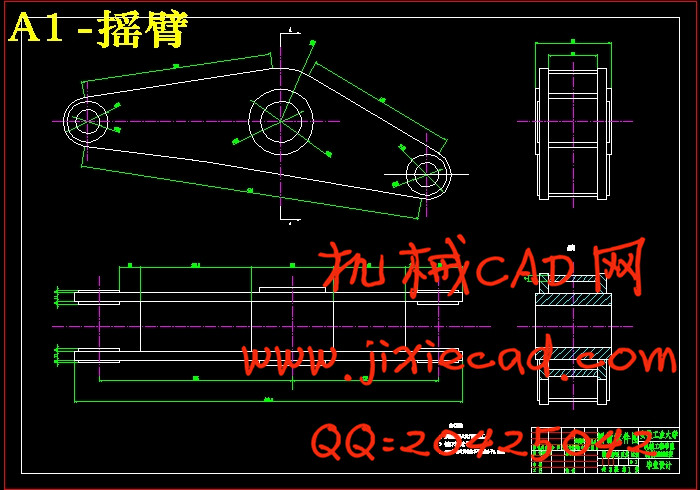

本文设计的是一种微型挖掘机,作在为工业、民用上有特殊用途的装载机械,它可以用于煤矿井下狭小空间的清理、装载、运输等工作,也可以用于冶金、矿山、隧道建设等场合的挖掘装载工作。在本设计中,通过对国内外现有技术的了解和分析,利用任务书上所给定的挖掘机铲斗额定装载载荷,先计算出铲斗的斗容,而后选用标准容量的铲斗,根据所选出的标准铲斗,计算出挖掘机的最大铲取阻力、最大卸载高度、最小卸载距离等一些设计所必需用到的量。通过对工作机构上九个铰接点位置的确定来设计出动臂的模型及动臂上各点的受力,然后计算出举臂油缸和转斗油缸的内径、活塞杆的杆径,选出标准的液压缸。根据转台以上部分的重力计算选择马达和滚动轴承,然后设计出相应的行走装置。

关键词:铲斗、液压缸、动臂、挖掘机

Abstract

What this text design is a micro-excavator which has special use in the fields of industry and agriculture. It can work in a narrow and small place to clean carry and transport the stones and it can be used in metallurgy, digging mine and tunnel construction as well. By consulting the latest professional technology and theories, taking account of the practical need of the market and making use of the given rated weight from the task paper, I firstly calculate the capacity of bucket and then select standard bucket data to calculate some essential data such as the largest scooping resistance, the largest unloading height and the largest unloading distance, etc. Through the position of nine attachment points in the system I initially design the arm model and the force of all points. By analyzing the force of the tow important points, calculate the diameter of the raising arm cylinder and the turning bucket, and the diameter of the piston pole, and the distance of travel of the piston, then select the standard cylinder.

According to the gravities of the above parts, calculate and select the motor and the roll over the bearings. Then design the device of the walk

Key words: bucket ,cylinder, the moving arm ,excavator

目录

中文摘要……………………………………………………………… 3

英文摘要 ………………………………………………………………4

正文

1行走装置 ………………………………………………………… 7

1.1构造和传动形式 ………………………………………………7

1.2行走系的设计…………………………………………………… 8

1.3四轮一带等有关参数的初步确定和行走结构布置………………8

2回转装置 …………………………………………………………… 9

2.1滚动轴承式回转支承 …………………………………………10

2.2回转机构 …………………………………………………… 11

2.3转台 …………………………………………………………… 12

3工作机构设计 ………………………………………………………15

3.1装载工作对工作机构设计的要求 ………………………………15

3.2履带式挖掘机工作机构的类型的综合分析和选用 …………16

3.3铲斗 ………………………………………………………………18

3.4工作机构连杆系统的尺寸参数设计 ……………………………19

3.5工作机构的强度计算 ………………………………………… 25

3.6转斗油缸和举臂油缸的设计 ………………………………… 28

结论 ………………………………………………………………32

谢辞 ………………………………………………………………33

参考文献 …………………………………………………………34

附录 ………………………………………………………………35

中英文翻译及原文 …………………………………………………35

翻译 …………………………………………………………………35

本文设计的是一种微型挖掘机,作在为工业、民用上有特殊用途的装载机械,它可以用于煤矿井下狭小空间的清理、装载、运输等工作,也可以用于冶金、矿山、隧道建设等场合的挖掘装载工作。在本设计中,通过对国内外现有技术的了解和分析,利用任务书上所给定的挖掘机铲斗额定装载载荷,先计算出铲斗的斗容,而后选用标准容量的铲斗,根据所选出的标准铲斗,计算出挖掘机的最大铲取阻力、最大卸载高度、最小卸载距离等一些设计所必需用到的量。通过对工作机构上九个铰接点位置的确定来设计出动臂的模型及动臂上各点的受力,然后计算出举臂油缸和转斗油缸的内径、活塞杆的杆径,选出标准的液压缸。根据转台以上部分的重力计算选择马达和滚动轴承,然后设计出相应的行走装置。

关键词:铲斗、液压缸、动臂、挖掘机

Abstract

What this text design is a micro-excavator which has special use in the fields of industry and agriculture. It can work in a narrow and small place to clean carry and transport the stones and it can be used in metallurgy, digging mine and tunnel construction as well. By consulting the latest professional technology and theories, taking account of the practical need of the market and making use of the given rated weight from the task paper, I firstly calculate the capacity of bucket and then select standard bucket data to calculate some essential data such as the largest scooping resistance, the largest unloading height and the largest unloading distance, etc. Through the position of nine attachment points in the system I initially design the arm model and the force of all points. By analyzing the force of the tow important points, calculate the diameter of the raising arm cylinder and the turning bucket, and the diameter of the piston pole, and the distance of travel of the piston, then select the standard cylinder.

According to the gravities of the above parts, calculate and select the motor and the roll over the bearings. Then design the device of the walk

Key words: bucket ,cylinder, the moving arm ,excavator

目录

中文摘要……………………………………………………………… 3

英文摘要 ………………………………………………………………4

正文

1行走装置 ………………………………………………………… 7

1.1构造和传动形式 ………………………………………………7

1.2行走系的设计…………………………………………………… 8

1.3四轮一带等有关参数的初步确定和行走结构布置………………8

2回转装置 …………………………………………………………… 9

2.1滚动轴承式回转支承 …………………………………………10

2.2回转机构 …………………………………………………… 11

2.3转台 …………………………………………………………… 12

3工作机构设计 ………………………………………………………15

3.1装载工作对工作机构设计的要求 ………………………………15

3.2履带式挖掘机工作机构的类型的综合分析和选用 …………16

3.3铲斗 ………………………………………………………………18

3.4工作机构连杆系统的尺寸参数设计 ……………………………19

3.5工作机构的强度计算 ………………………………………… 25

3.6转斗油缸和举臂油缸的设计 ………………………………… 28

结论 ………………………………………………………………32

谢辞 ………………………………………………………………33

参考文献 …………………………………………………………34

附录 ………………………………………………………………35

中英文翻译及原文 …………………………………………………35

翻译 …………………………………………………………………35