设计简介

6SX-320型叶菜清洗机的设计研究

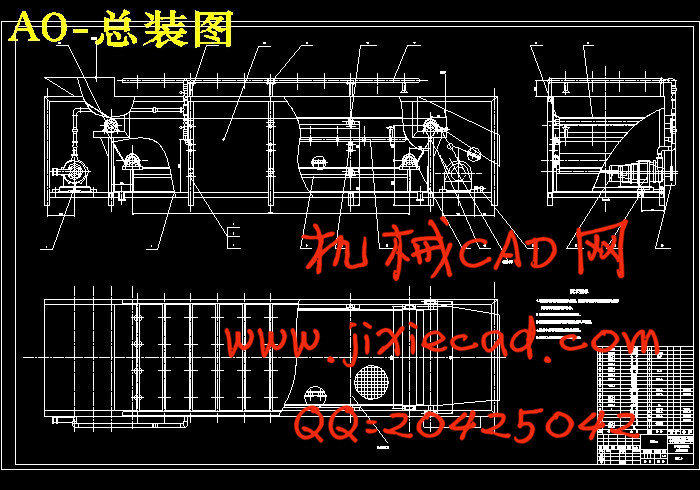

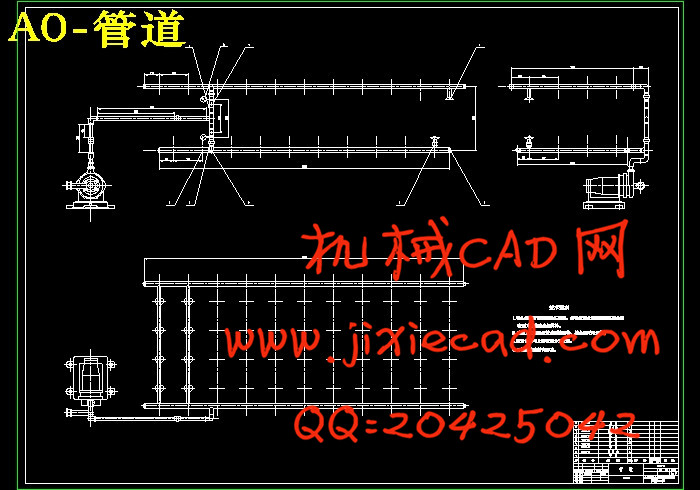

摘 要 本文论述了研制自动化连续型叶菜清洗机的必要性和可行性。叶类蔬菜表面残存有尘土、有机肥、及残存的化学农药、微生物等,且叶类蔬菜本身比较嫩脆,容易折断压溃,我们针对叶状类蔬菜的特点,设计了6SX-320型叶状类蔬菜清洗机,并介绍了其工艺流程和整体结构。6SX-320型叶状类蔬菜清洗机的工艺流程为浸泡清洗 -- 喷淋清洗 -- 超声波净洗 -- 出菜。

利用高于20KHZ的超音频电能的超声波,能通过换能器转换成高频机械振荡而传入到清洗液中。超声波在清洗液中疏密地向前辐射,使液体移动,并产生数万计的微小气泡,这些气泡在超声波纵向传播的负压区形成、生产、迅速闭合称为空化现象。在空化现象中气泡闭合时形成超过1000个大气压的瞬时高压,连续不断产生的瞬时高压就像一连串小爆炸不断地轰击物体表面,使物体表面及缝隙中污垢迅速剥落,这种空化侵蚀作用就是超声波清洗的基本原理。

关键词 自动化 浸泡 喷淋 超声波清洗 水处理

The Design Study about The 6SX-320-type washing

Machine for Vegetable

Abstract

This article discusses the development of automated continuous washing machine leafy vegetables need and feasibility. The surface of the leaf type vegetables remains to have dust, orangic fat. Chomical agriculture chemical and microorganism. And it is fresh and flat, getting easy to be rolled over . We focused on the characteristics of phyllodes vegetables designed 6SX-320-type leaf-like vegetable washing machine, and presented the overall structure of the process. Model 6SX-320 rhizome type vegetables wash machine adopt cylinder. And the processes of the Model 6SX-320 leaf form type wash machine is immersion washing—spray washing—ultrasonic wave washing—bringing the vegetables out.

The height frequently effect ultrasonies which are more than 20 KHZ are translates the mechanical vibrational via the exchanged energy organ and transmitted into the intermedium.Nonstopped vibration of ultrasonic made the liquid moved forward in the intermedium and can give birth to ten thousands of little air bubble. It is called for around-the-clock that the air bubbles form, develop and shut up rapidly in the pressure region of the track of the ultrasonic moving. The opening of the air bubbles form one thousand of air pressure. The lash of the surface of cleaned object continuous and continuous which likes giving birth to dense explosion on the surface of cleaned object made the grease stain fabled off. The fun dametal is the theory of ultrasonic cleaning.

Keywords automize soak gush out and drench ultrasonic washing water treatment

目录

1.引言…………………………………………………………………………………1

1.1叶菜清洗目的…………………………………………………………………….2

1.2清洗工艺及设备设计的要求…………………………………………………….3

1.3常见方案分析…………………………………………………………………….3

1.3.1刷淋式清洗机…………………………………………………………………..3

1.3.2桨叶式清洗机…………………………………………………………………..4

1.3.3浸泡式清洗机…………………………………………………………………..5

1.3.4滚筒式清洗机…………………………………………………………………..6

1.3.5螺旋式清洗机…………………………………………………………………..7

2.方案的设计…………………………………………………………………………7

2.1概述……………………………………………………………………………….7

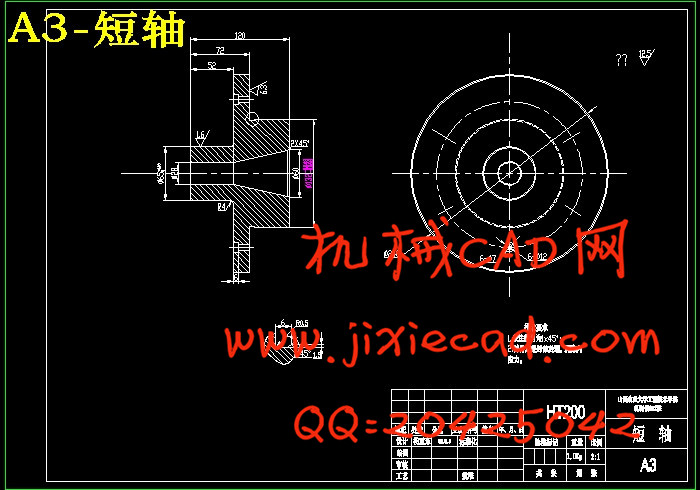

2.2机械结构的设计……………………………………………………………….…8

2.2.1初步估算功率……………………………………………………………….….8

2.2.2减速器的选择……………………………………………………………….….9

2.2.3传动机构的设计计算…………………………………………………….…….9

2.2.4张紧机构的设计……………………………………………………………….13

2.2.5缸体的设计…………………………………………………………………….13

2.3辅助设备的设计…………………………………………………………………13

2.3.1泵的选择……………………………………………………………………….13

2.3.2轴承的选择…………………………………………………………………….14

2.3.3滚动轴承座的选择………………………………………………………….…15

3.超声波清洗机………………………………………………………………….…..15

3.1超声波和气泡清洗蔬菜的机理探讨……………………………………………15

3.1.1超声波清洗蔬菜的机理………………………………………………….……15

3.1.2气泡清洗蔬菜的机理………………………………………………….………16

3.2清洗工艺参数的确定……………………………………………………………17

3.3叶菜清洗机结构设计………………………………………………………….....18

4.清洗废水的处理…………………………………………………………………...18

5.远红外干燥杀菌…………………………………………………………………...19

小结……………………………………………………………...…………………...20

参考文献……………………………………………………………………………..23

致谢…………………………………………………………………………………..24

摘 要 本文论述了研制自动化连续型叶菜清洗机的必要性和可行性。叶类蔬菜表面残存有尘土、有机肥、及残存的化学农药、微生物等,且叶类蔬菜本身比较嫩脆,容易折断压溃,我们针对叶状类蔬菜的特点,设计了6SX-320型叶状类蔬菜清洗机,并介绍了其工艺流程和整体结构。6SX-320型叶状类蔬菜清洗机的工艺流程为浸泡清洗 -- 喷淋清洗 -- 超声波净洗 -- 出菜。

利用高于20KHZ的超音频电能的超声波,能通过换能器转换成高频机械振荡而传入到清洗液中。超声波在清洗液中疏密地向前辐射,使液体移动,并产生数万计的微小气泡,这些气泡在超声波纵向传播的负压区形成、生产、迅速闭合称为空化现象。在空化现象中气泡闭合时形成超过1000个大气压的瞬时高压,连续不断产生的瞬时高压就像一连串小爆炸不断地轰击物体表面,使物体表面及缝隙中污垢迅速剥落,这种空化侵蚀作用就是超声波清洗的基本原理。

关键词 自动化 浸泡 喷淋 超声波清洗 水处理

The Design Study about The 6SX-320-type washing

Machine for Vegetable

Abstract

This article discusses the development of automated continuous washing machine leafy vegetables need and feasibility. The surface of the leaf type vegetables remains to have dust, orangic fat. Chomical agriculture chemical and microorganism. And it is fresh and flat, getting easy to be rolled over . We focused on the characteristics of phyllodes vegetables designed 6SX-320-type leaf-like vegetable washing machine, and presented the overall structure of the process. Model 6SX-320 rhizome type vegetables wash machine adopt cylinder. And the processes of the Model 6SX-320 leaf form type wash machine is immersion washing—spray washing—ultrasonic wave washing—bringing the vegetables out.

The height frequently effect ultrasonies which are more than 20 KHZ are translates the mechanical vibrational via the exchanged energy organ and transmitted into the intermedium.Nonstopped vibration of ultrasonic made the liquid moved forward in the intermedium and can give birth to ten thousands of little air bubble. It is called for around-the-clock that the air bubbles form, develop and shut up rapidly in the pressure region of the track of the ultrasonic moving. The opening of the air bubbles form one thousand of air pressure. The lash of the surface of cleaned object continuous and continuous which likes giving birth to dense explosion on the surface of cleaned object made the grease stain fabled off. The fun dametal is the theory of ultrasonic cleaning.

Keywords automize soak gush out and drench ultrasonic washing water treatment

目录

1.引言…………………………………………………………………………………1

1.1叶菜清洗目的…………………………………………………………………….2

1.2清洗工艺及设备设计的要求…………………………………………………….3

1.3常见方案分析…………………………………………………………………….3

1.3.1刷淋式清洗机…………………………………………………………………..3

1.3.2桨叶式清洗机…………………………………………………………………..4

1.3.3浸泡式清洗机…………………………………………………………………..5

1.3.4滚筒式清洗机…………………………………………………………………..6

1.3.5螺旋式清洗机…………………………………………………………………..7

2.方案的设计…………………………………………………………………………7

2.1概述……………………………………………………………………………….7

2.2机械结构的设计……………………………………………………………….…8

2.2.1初步估算功率……………………………………………………………….….8

2.2.2减速器的选择……………………………………………………………….….9

2.2.3传动机构的设计计算…………………………………………………….…….9

2.2.4张紧机构的设计……………………………………………………………….13

2.2.5缸体的设计…………………………………………………………………….13

2.3辅助设备的设计…………………………………………………………………13

2.3.1泵的选择……………………………………………………………………….13

2.3.2轴承的选择…………………………………………………………………….14

2.3.3滚动轴承座的选择………………………………………………………….…15

3.超声波清洗机………………………………………………………………….…..15

3.1超声波和气泡清洗蔬菜的机理探讨……………………………………………15

3.1.1超声波清洗蔬菜的机理………………………………………………….……15

3.1.2气泡清洗蔬菜的机理………………………………………………….………16

3.2清洗工艺参数的确定……………………………………………………………17

3.3叶菜清洗机结构设计………………………………………………………….....18

4.清洗废水的处理…………………………………………………………………...18

5.远红外干燥杀菌…………………………………………………………………...19

小结……………………………………………………………...…………………...20

参考文献……………………………………………………………………………..23

致谢…………………………………………………………………………………..24