设计简介

摘要

随着社会经济和科学研究的不断发展,市场竞争日益激烈,因此各起重机生产企业都迫切想要改进生产技术,提高生产效率,制造行业中对桥式起重机的要求越来越高,性能也越来越全面。本设计为桥式起重机的小车运行机构部分,起重小车是沿着小车轨道横向行驶,吊钩则做升降运动。它的工作范围是其行驶地段的长方体空间,因此适合一般车间的工作形式。该小车有四个行走轮,布置各零部件时,应使机构总重心能接近小车架的纵向中心线,以便能最后比较均匀的小车轮压。

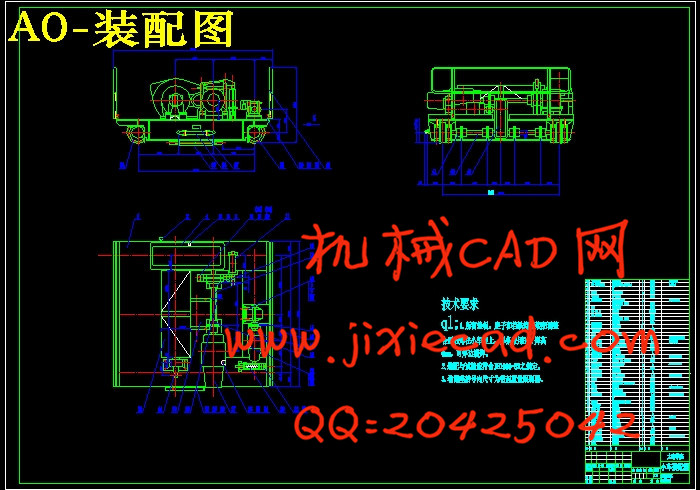

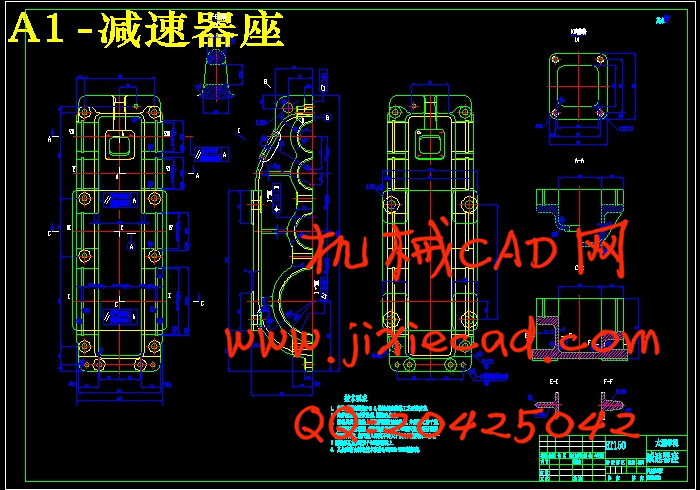

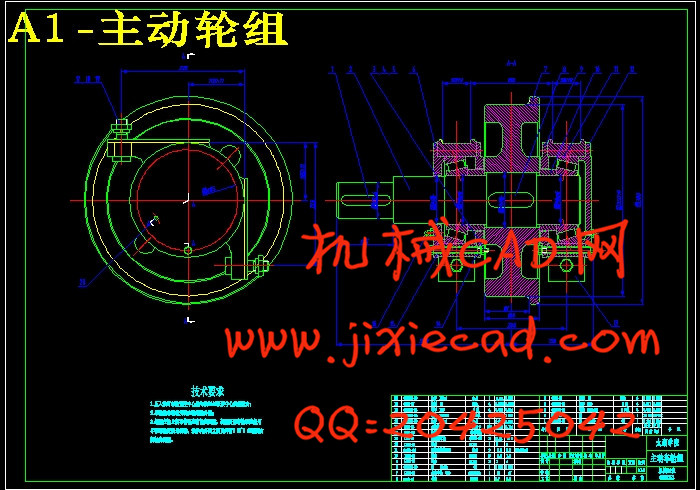

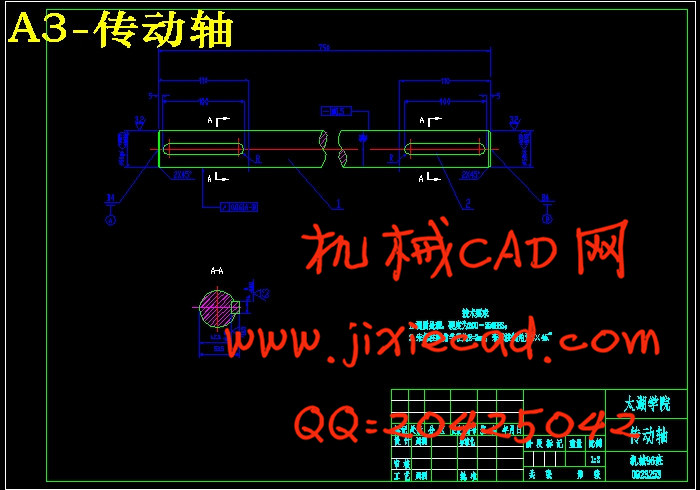

首先,确定了小车运行机构的传动方案为闭式齿轮传动,电动机与减速减速器直接连接,减速器在在小车中间的运行机构;其次:通过对小车运行机构部分的总体设计计算,以及电动机、联轴器、缓冲器、制动器等的计算和选用;运行机构的减速器的设计计算和零件的校核计算及结构设计,完成了小车运行机构这一重要机构机械部分的设计。通过这一系列的设计,满足了起重量达到10T 的要求,并且小车运行机构结构简单,拆装方便,易于维修。

关键词:起重小车,运行机构,减速器,设计

Abstract

With the continuous development of social economy and scientific research, the market increasingly competitive, so every crane production enterprise urgently want to improve production technology, improve production efficiency, manufacturing industry requirement for bridge crane is more and more high, performance is becoming more and more comprehensive.This design for the trolley traveling mechanism part of the bridge crane, lifting trolley along the transverse moving trolley track, lifting hook, do sports. Its scope of work is the driving section of cuboid space, thus is suitable for general workshop of the work of the form. Walk the car has four wheels, decorate parts, should be can make organization's center of gravity is close to the car frame longitudinal centerline, small wheel pressure so that can last more evenly.

First of all, determine the scheme of closed gear drive transmission trolley traveling mechanism, motor and reducer reducer connected directly, the reducer in the small car in the middle of the operation mechanism; Second: the car running part of the overall organization design and calculation, as well as the motor, coupling, shock absorber, brake, etc. The calculation and selection of; Operation of reducer design calculation and check calculation and structure design of the parts, completed the car running mechanism is an important mechanical part design. Through this series of design, meet the requirements of the lifting weight reached 10 t, and the car running mechanism has simple structure, easy tear open outfit, easy to maintenance.

Key words: lifting the car, run institutions, reducer, design

目录

摘要 III

Abstract IV

目录 V

1. 绪论 1

1.1序言 1

1.2 行业发展状况 1

1.3 起重机电气控制技术未来的发展趋势 2

2 桥式起重机的介绍 3

2.1 桥式起重机的组成和特点 3

2.1.1 起重机械的组成 3

2.2 国内外桥式起重机的发展趋势 3

2.2.1国内桥式起重机的发展趋势 3

2.2.2 国外桥式起重机的发展趋势 4

2.3 桥式起重机小车 6

2.3.1 桥式起重机小车运行机构 9

3 小车运行机构设计 10

3.1 设计小车的基本原则和要求 10

3.2 小车运行机构传动方案 10

3.2.1带有开式齿轮传动的方案(图3.1) 11

3.2.2全部为闭式齿轮的传动方案 11

3.3 选择车轮与轨道并验算其强度 13

3.3.1 疲劳计算 14

3.3.2 强度校合 15

3.4 运行阻力的计算 15

3.5 电动机的选用 16

3.5.1 电动机选用 16

3.5.2 验算电动机发热条件 16

3.6 减速器的计算与设计 16

3.6.1 减速器设计 16

3.6.2 减速器各轴的传递功率、转速、转矩 17

3.6.3 高速级齿轮的计算 18

3.6.4 中速级齿轮的计算 21

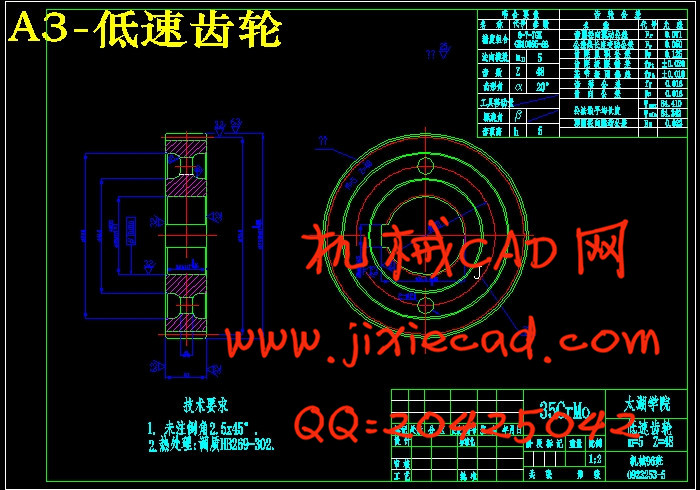

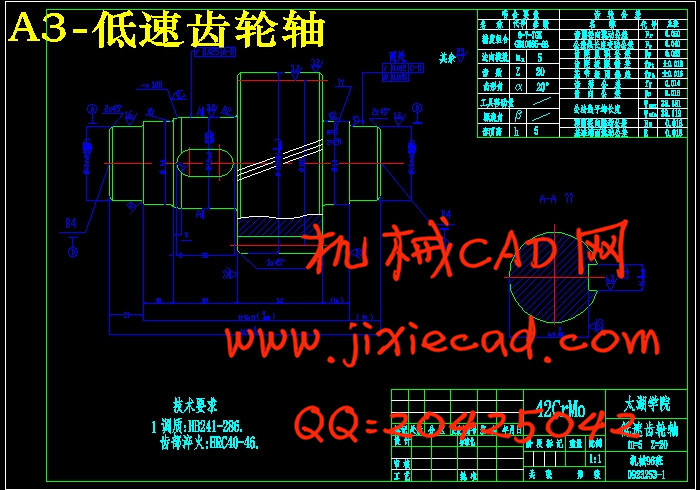

3.6.5 低速级齿轮的计算 24

3.6.6 齿轮的结构形式 28

3.6.7 减速器箱体及其附件 28

3.6.8减速器附件设计 28

3.7 运行速度和实际所需功率 29

3.7.1 实际运行速度 29

3.7.2 实际所需等效功率 29

3.8 验算起动条件 29

3.9 按起动工况校核减速器功率 30

3.10 起动不打滑条件 30

3.11 制动轮的计算 31

3.12 高速轴联轴器及制动器 32

3.13 低速轴联轴器的选用 32

3.14 验算低速浮动轴强度 33

3.14.1 疲劳验算 33

3.14.2 静强度计算 33

4 小车架的设计 35

4.1 确定小车架的型式 35

4.2 确定小车架的结构 35

4.3 箱形梁的校核 36

4.3.1 横梁的强度计算 36

4.3.2 纵梁的扭转计算 38

5 总结与不足 40

致 谢 41

参考文献 42