设计简介

18t桥式起重机设计

摘要:

桥式起重机是一种提高劳动生产率重要物品搬运设备,主要适应车间物品搬运、设备的安装与检修等用途。我国生产的吊钩电动双梁桥式起重机额定起重范围为5~500t,一般10t以上,起重机有主、副两套起升机构;300t以上,起重机还有三套起升机构。

电动双梁起重机由桥架、小车运行机构、大车运行机构和电气设备构成。在系统整体设计中采用传统布局的典型结构,小车运行机构采用集中驱动。起升机构滑轮组采用双联滑轮组,重物在升降过程中没有水平移动,起升过程平稳,且钢丝绳的安装和更换容易。相应的卷绕装置采用单层卷筒,有与钢丝绳接触面积大,单位压力低的优点。在起升机构中还涉及到钢丝绳、减速器、联轴器、电动机和制动器的选择等。小车运行机构中涉及小车轮压计算、小车车轮、小车轨道、减速器、联轴器、电动机和制动器的选择计算等。

在起重机控制方面,起升机构用主令控制器和磁力控制屏来实现控制,大、小车运行机构用凸轮控制器直接控制。在控制系统设计中,主要针对起升机构、大车运行机构、小车运行机构电路控制系统的设计及保护电路的设计。利用低压电气元件控制起重机,其使用寿命较长,适合车间恶劣环境。

关键词:桥式起重机 节点控制器 电气控制系统

ABSTRACT

Bridge crane is a significant increase labor productivity goods handling equipment, primarily to carry goods workshops, equipment installation and maintenance, and other purposes. China's production of electrical hook rated double-beam bridge crane lifting the range of 5 ~ 500 t, generally more than 10 t, cranes are the main, two sets of lifting300 t above, there are three sets of cranes lifting bodies.

Two-electric beam from the bridge crane, the trolley running, traveling mechanism and electrical equipment constituted. The overall design of the system using the traditional layout of the typical structure and operation of institutions used car driven focus. Pulley group or agency from using double-pulley blocks, heavy objects in the process of lifting the level of no movement, or from the process smooth, and the installation and replacement of wire rope easily. Winding installations in the corresponding single reel, a large area of contact with the rope, the advantages of low pressure units. In lifting bodies also involves rope, reducer, couplings, electrical and brake the choice. Vehicles involved in the operation of institutions pressure on the wheels, car wheels, car track, reducer, couplings, electrical and brake the choice of calculation.

In the crane control, or from the institutions with the main controller and magnetic control of the screen to achieve control, big and small car cam controller running institutions with direct control. In the control system design, mainly for lifting bodies, traveling mechanism, the car run institutions circuit design and control system for the protection of the circuit design. Use of low-voltage electrical components control crane, a longer service life for workshop harsh environment.

Key words: Bridge crane Node Controller Electric control system

目 录

摘要 1

第一章 绪论 3

1.1桥式起重机的简介 3

1.2普通桥式起重机的主要组成部分 3

1.2.1 大车 3

1.2.2 小车 3

1.2.3动力装置和控制系统 3

1.3普通桥式起重机的运行方式 3

第二章 设计任务及技术参数 5

2.1主要技术参数: 5

2.2起重机工作机构的级别: 5

第三章 18吨桥式起重机的控制系统设计 6

3.1控制电路设计分析 6

3.1.1控制对象分析及控制元件的确定 6

3.1.2控制系统的基本要求 6

3.1.3电动机的工作状态分析 6

3.1.4起重机的供电 9

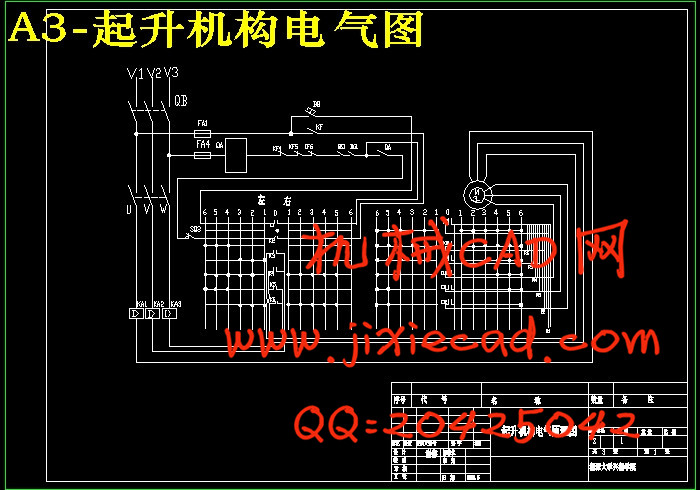

3.2起升机构控制电路工作原理 9

3.2.1起升机构电路的特点 9

3.2.2起升机构电路的保护与联锁 10

3.2.3起升机构电气工作控制原理 11

3.3小车运行机构电路工作原理 14

3.3.1小车运行机构电路工作特点 14

3.3.2小车运行机构的电气控制原理 14

3.4大车运行机构电路工作原理 16

3.4.1大车运行机构电路的工作特点 16

3.4.2大车运行机构的电气控制原理 16

3.5保护电路的工作原理 18

3.5.1保护电路的组成 18

3.5.2保护电路的工作过程 18

结束语 20

参考文献 21

附录一 22

附录二 27

摘要:

桥式起重机是一种提高劳动生产率重要物品搬运设备,主要适应车间物品搬运、设备的安装与检修等用途。我国生产的吊钩电动双梁桥式起重机额定起重范围为5~500t,一般10t以上,起重机有主、副两套起升机构;300t以上,起重机还有三套起升机构。

电动双梁起重机由桥架、小车运行机构、大车运行机构和电气设备构成。在系统整体设计中采用传统布局的典型结构,小车运行机构采用集中驱动。起升机构滑轮组采用双联滑轮组,重物在升降过程中没有水平移动,起升过程平稳,且钢丝绳的安装和更换容易。相应的卷绕装置采用单层卷筒,有与钢丝绳接触面积大,单位压力低的优点。在起升机构中还涉及到钢丝绳、减速器、联轴器、电动机和制动器的选择等。小车运行机构中涉及小车轮压计算、小车车轮、小车轨道、减速器、联轴器、电动机和制动器的选择计算等。

在起重机控制方面,起升机构用主令控制器和磁力控制屏来实现控制,大、小车运行机构用凸轮控制器直接控制。在控制系统设计中,主要针对起升机构、大车运行机构、小车运行机构电路控制系统的设计及保护电路的设计。利用低压电气元件控制起重机,其使用寿命较长,适合车间恶劣环境。

关键词:桥式起重机 节点控制器 电气控制系统

ABSTRACT

Bridge crane is a significant increase labor productivity goods handling equipment, primarily to carry goods workshops, equipment installation and maintenance, and other purposes. China's production of electrical hook rated double-beam bridge crane lifting the range of 5 ~ 500 t, generally more than 10 t, cranes are the main, two sets of lifting300 t above, there are three sets of cranes lifting bodies.

Two-electric beam from the bridge crane, the trolley running, traveling mechanism and electrical equipment constituted. The overall design of the system using the traditional layout of the typical structure and operation of institutions used car driven focus. Pulley group or agency from using double-pulley blocks, heavy objects in the process of lifting the level of no movement, or from the process smooth, and the installation and replacement of wire rope easily. Winding installations in the corresponding single reel, a large area of contact with the rope, the advantages of low pressure units. In lifting bodies also involves rope, reducer, couplings, electrical and brake the choice. Vehicles involved in the operation of institutions pressure on the wheels, car wheels, car track, reducer, couplings, electrical and brake the choice of calculation.

In the crane control, or from the institutions with the main controller and magnetic control of the screen to achieve control, big and small car cam controller running institutions with direct control. In the control system design, mainly for lifting bodies, traveling mechanism, the car run institutions circuit design and control system for the protection of the circuit design. Use of low-voltage electrical components control crane, a longer service life for workshop harsh environment.

Key words: Bridge crane Node Controller Electric control system

目 录

摘要 1

第一章 绪论 3

1.1桥式起重机的简介 3

1.2普通桥式起重机的主要组成部分 3

1.2.1 大车 3

1.2.2 小车 3

1.2.3动力装置和控制系统 3

1.3普通桥式起重机的运行方式 3

第二章 设计任务及技术参数 5

2.1主要技术参数: 5

2.2起重机工作机构的级别: 5

第三章 18吨桥式起重机的控制系统设计 6

3.1控制电路设计分析 6

3.1.1控制对象分析及控制元件的确定 6

3.1.2控制系统的基本要求 6

3.1.3电动机的工作状态分析 6

3.1.4起重机的供电 9

3.2起升机构控制电路工作原理 9

3.2.1起升机构电路的特点 9

3.2.2起升机构电路的保护与联锁 10

3.2.3起升机构电气工作控制原理 11

3.3小车运行机构电路工作原理 14

3.3.1小车运行机构电路工作特点 14

3.3.2小车运行机构的电气控制原理 14

3.4大车运行机构电路工作原理 16

3.4.1大车运行机构电路的工作特点 16

3.4.2大车运行机构的电气控制原理 16

3.5保护电路的工作原理 18

3.5.1保护电路的组成 18

3.5.2保护电路的工作过程 18

结束语 20

参考文献 21

附录一 22

附录二 27