设计简介

摘要

焊接与铸造、锻压、切削加工、热处理等金属加工工艺组合,成为机械制造业的主要加工方法,许多传统的铸锻产品,也由焊接制品或铸—焊、锻—焊制品所代替。焊接结构生产的整个过程同其他任何一生产过程一样,除了基本的生产工序以外,还包括大量的辅助工序,其中主要是焊接零件的制备、装配、工序间的传送和制品的变位与清理等。

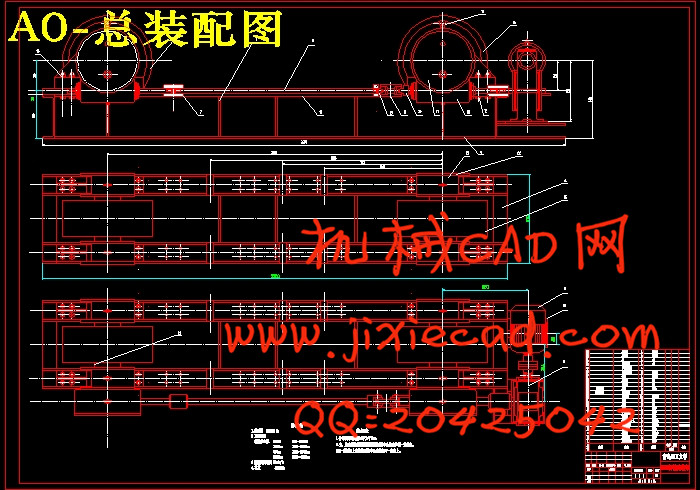

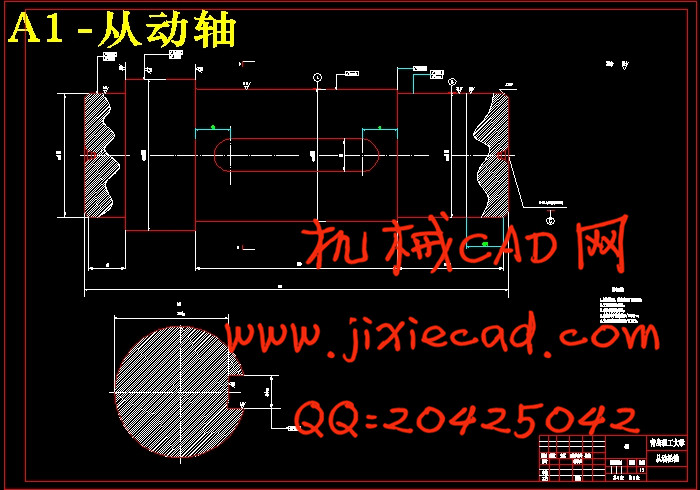

通过载重量计算出轴、轴承、联轴器等的具体尺寸、并对其进行校核。初期进行传动比的分配,主动轮上的功率除以传动效率从而算出需要的电机功率,从而选择电动机,再将电动机的转速进行分配算出减速器、涡轮蜗杆。

关键词: 焊接;生产工艺质量;焊接滚轮架;筒形工件

bstract

Welding and casting, forging, machining, heat treatment and other metalprocessing technology portfolio and become the main processing machinery manufacturing methods, the Casting and Forging in many traditional products, but also by the welding or casting products - welding, forging - replaced by welding products.

Welded structure with the entire process of production of any other as a production process, in addition to the basic production processes, but also including a large number of auxiliary procedures, which are mainly parts of the preparation of welding, assembly, delivery and inter-process products such as variable bit with the clean-up .

Load is calculated through the shaft, bearings, couplings, such as the specific size, and check them. The initial stage of the distribution of the transmission ratio, active power divided by the number of launches in order to calculate the transmission efficiency of the electric power needs in order to select the motor, and then carry out the distribution of motor speed reducercalculated, turbine worm.

Key words: welding; production process quality; welding wheel frame; cylindrical workpiece

目录

摘要 ..I

Abstract II

目录 Ⅲ

前言 1

第1章 绪论 2

1.1焊接工艺概述 2

1.2 工艺装备与生产的工艺的关系 2

1.3 焊接工艺装备 5

第2章 滚轮架概述 9

2.1 滚轮架分类 9

2.2 中心角与驱动力、支反力的关系 9

2.3滚轮驱动方案 10

第3章 滚轮架的设计与校核 13

3.1 电动机的选择 13

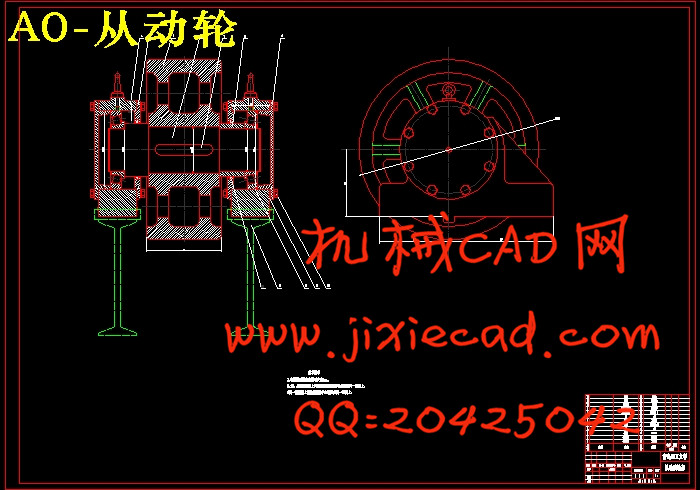

3.2 从动轮的设计 14

3.3 圆柱蜗杆的设计 18

结论 22

参考文献 23

致谢 24