设计简介

摘要

针对传统钻探行业施工过程中设备搬迁困难、钻孔效率低以及无法倾斜钻探等问题,研制、改进新一代高效可倾式钻探设备则显得尤为必要。该矿用钻机改型过程中所面对的若干问题进行了较为详细研究,并对关键件加工过程出现的工艺文体进行分析和调整。

通过调研了解到,对钻孔深度100米左右的钻机需求量比较大,而目前的100米钻机,存在着劳动强度大、适应性差等缺点。鉴于以上原因,我们决定开发100米钻机。经几次方案讨论决定,钻机应具有以下特点:经济耐用可靠、质优价廉;便于解体搬运;体积小,重量轻;操作简单,维修方便;适用于Φ42、Φ50mm两种钻杆;

适用于合金钻头或金刚石钻头钻进;钻进速度快,效率高;动力为电机或柴油机。

关键词:100米 变速箱 钻机

bstract

the equipment moves the difficulty in view of the traditional drilling profession construction process in, the drill hole efficiency lowers as well as is unable to incline questions and so on drilling, the development, improves new one generation highly effective to be possible to lean the type drilling equipment to appear especially essential. In this mineral product drilling machine modification process faces certain questions have conducted the comparatively dissect, and the craft literary style which appears to the key processing process carries on the analysis and the adjustment.

Understood through the investigation and study, quite is big to the drill hole depth 100 meter about drilling machine demands, but the present 100 meters drilling machines, have the labor intensity in a big way, the compatible inferior shortcoming. In view of the fact that above reason, we decided develops 100 meters drilling machines. Decided after several plan discussions that, the drilling machine should have following characteristic: economy durable reliable, high quality at low price; is advantageous for the disintegration transporting; the volume is small, the weight is light; the operation is simple, the service is convenient; is suitable for φ42, φ50mm two kind of drill rods; is suitable in the alloy drill bit or the carbon bit sneaks in; sneaks in the speed to be quick, the efficiency is high; the power is the electrical machinery or the diesel engine.

Kewords: drilling machines 100 meters gearbox

目 录

摘要 Ⅰ

Abstract Ⅱ

绪论 1

第1章 总体设计 2

第2章 钻机的主要技术特性 3

第3章 动力确定 5

3.1 回转钻进及破碎岩层,土层所需功率 5

3.2 进给油缸所需功率计算 6

3.2.1 进给油缸的基本参数 6

3.2.2 油缸工作压力计算 6

3.2.3 油泵最大工作流量计算 7

3.2.4 进给油缸功率 7

3.3 动力机功率的确定 7

第4章 机械传动系统设计 10

4.1 要参数的选择 10

4.1.1 回转器 10

4.1.2 升降机 10

4.1.3 变速箱 10

4.2 机械传动系统 10

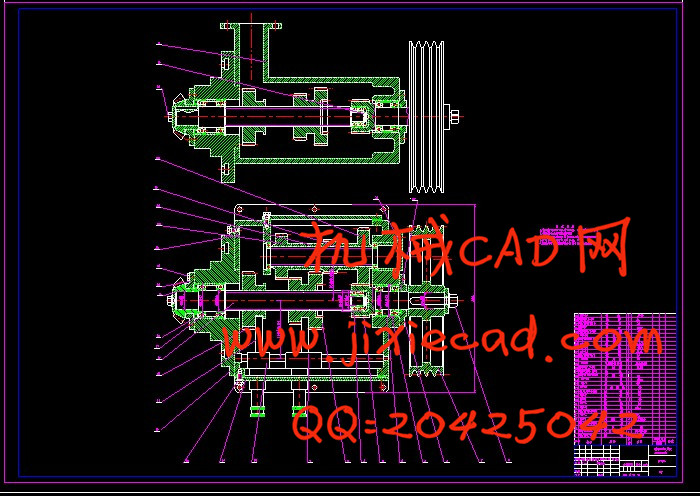

第5章 回转器 12

5.1 结构特点 12

5. 2 零部件的强度与寿命计算 12

5.2.1 齿面按接触疲劳强度计算 13

5.2.2 弯曲疲劳强度极限应力 13

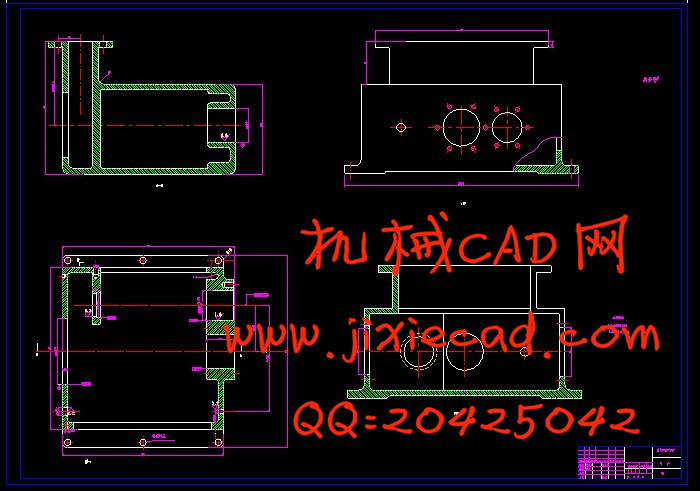

第6章 变速箱的设计与计算 15

6.1 变速箱的结构特点 15

6.2 零件的强度计算 15

6.3 齿轮的强度计算 15

6.4 轴系零部件强度与寿命的校核计算 20

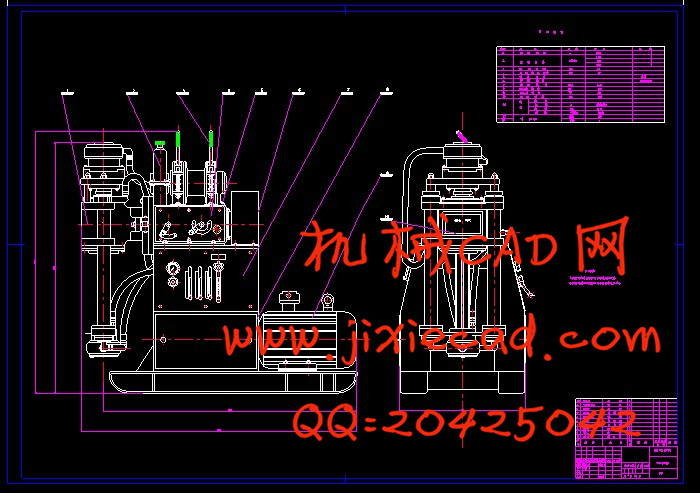

第7章 绞 车 24

7.1 结构特点 24

7.2 主要参数的选择 24

7.3 绞车所需功率 25

7.4 零部件的强度及寿命计算 25

第8章 液压系统的设计与计算 31

8.1 液压卡盘的设计与计算 31

8.2 进给油缸的设计 33

第9章 钻机的使用说明书 35

总结 50

致谢 51

参考文献 52

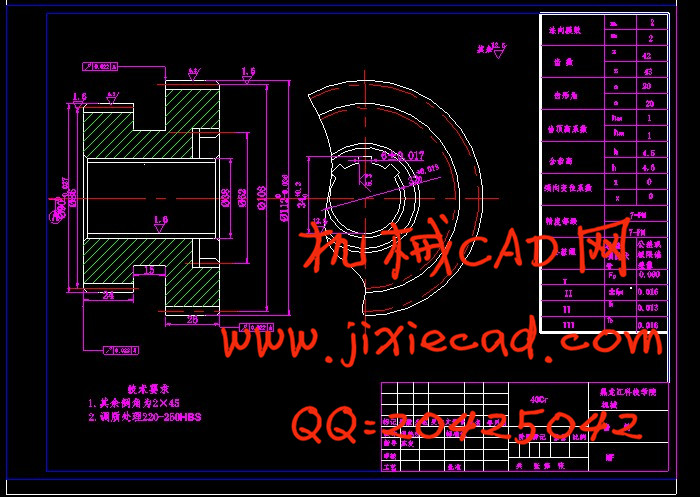

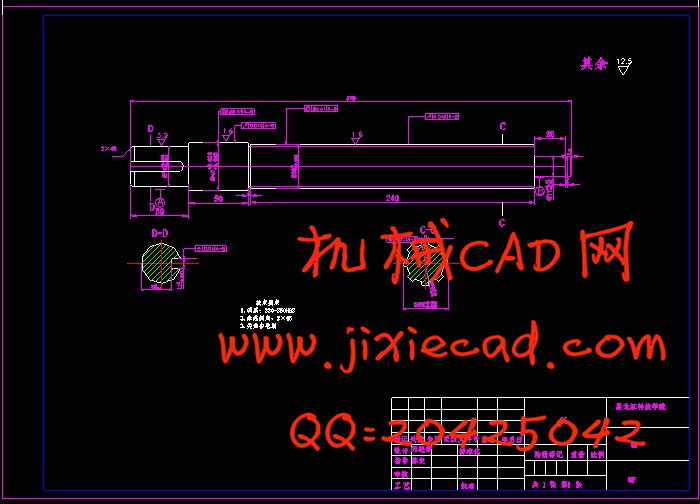

专题 轴的机械加工工艺过程 53

针对传统钻探行业施工过程中设备搬迁困难、钻孔效率低以及无法倾斜钻探等问题,研制、改进新一代高效可倾式钻探设备则显得尤为必要。该矿用钻机改型过程中所面对的若干问题进行了较为详细研究,并对关键件加工过程出现的工艺文体进行分析和调整。

通过调研了解到,对钻孔深度100米左右的钻机需求量比较大,而目前的100米钻机,存在着劳动强度大、适应性差等缺点。鉴于以上原因,我们决定开发100米钻机。经几次方案讨论决定,钻机应具有以下特点:经济耐用可靠、质优价廉;便于解体搬运;体积小,重量轻;操作简单,维修方便;适用于Φ42、Φ50mm两种钻杆;

适用于合金钻头或金刚石钻头钻进;钻进速度快,效率高;动力为电机或柴油机。

关键词:100米 变速箱 钻机

bstract

the equipment moves the difficulty in view of the traditional drilling profession construction process in, the drill hole efficiency lowers as well as is unable to incline questions and so on drilling, the development, improves new one generation highly effective to be possible to lean the type drilling equipment to appear especially essential. In this mineral product drilling machine modification process faces certain questions have conducted the comparatively dissect, and the craft literary style which appears to the key processing process carries on the analysis and the adjustment.

Understood through the investigation and study, quite is big to the drill hole depth 100 meter about drilling machine demands, but the present 100 meters drilling machines, have the labor intensity in a big way, the compatible inferior shortcoming. In view of the fact that above reason, we decided develops 100 meters drilling machines. Decided after several plan discussions that, the drilling machine should have following characteristic: economy durable reliable, high quality at low price; is advantageous for the disintegration transporting; the volume is small, the weight is light; the operation is simple, the service is convenient; is suitable for φ42, φ50mm two kind of drill rods; is suitable in the alloy drill bit or the carbon bit sneaks in; sneaks in the speed to be quick, the efficiency is high; the power is the electrical machinery or the diesel engine.

Kewords: drilling machines 100 meters gearbox

目 录

摘要 Ⅰ

Abstract Ⅱ

绪论 1

第1章 总体设计 2

第2章 钻机的主要技术特性 3

第3章 动力确定 5

3.1 回转钻进及破碎岩层,土层所需功率 5

3.2 进给油缸所需功率计算 6

3.2.1 进给油缸的基本参数 6

3.2.2 油缸工作压力计算 6

3.2.3 油泵最大工作流量计算 7

3.2.4 进给油缸功率 7

3.3 动力机功率的确定 7

第4章 机械传动系统设计 10

4.1 要参数的选择 10

4.1.1 回转器 10

4.1.2 升降机 10

4.1.3 变速箱 10

4.2 机械传动系统 10

第5章 回转器 12

5.1 结构特点 12

5. 2 零部件的强度与寿命计算 12

5.2.1 齿面按接触疲劳强度计算 13

5.2.2 弯曲疲劳强度极限应力 13

第6章 变速箱的设计与计算 15

6.1 变速箱的结构特点 15

6.2 零件的强度计算 15

6.3 齿轮的强度计算 15

6.4 轴系零部件强度与寿命的校核计算 20

第7章 绞 车 24

7.1 结构特点 24

7.2 主要参数的选择 24

7.3 绞车所需功率 25

7.4 零部件的强度及寿命计算 25

第8章 液压系统的设计与计算 31

8.1 液压卡盘的设计与计算 31

8.2 进给油缸的设计 33

第9章 钻机的使用说明书 35

总结 50

致谢 51

参考文献 52

专题 轴的机械加工工艺过程 53