设计简介

摘要

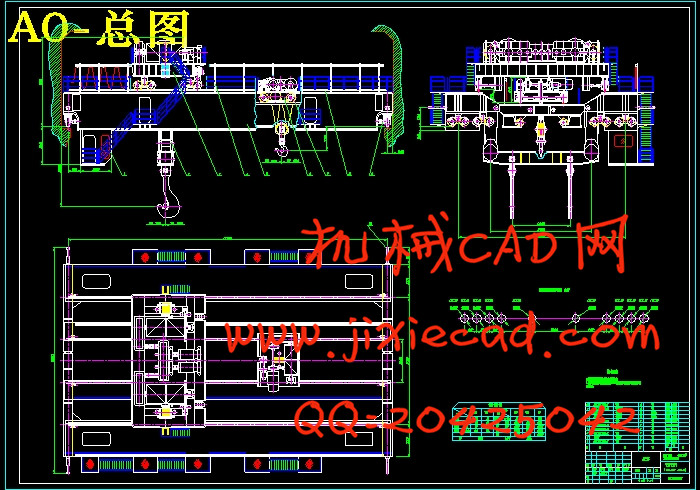

六梁铸造起重机是桥式起重机的重要组成部分,是中大型起重设备,由四根主梁和两根端梁组成。本设计采用偏轨箱型主梁,设计过程中从强度、刚度、稳定性三个方面来计算,对于A7工作级别的起重机来说还要进行疲劳强度校核,这就和A6以下工作级别的起重机的设计有了很大的区别,在设计时会出现静强度有很大的富余,在计算局部稳定性的时候还要注意局部轮压的作用,这时候需要验算加劲肋的区格验算,很有可能需要再次验算。设计中在满足刚度、强度、稳定性的前提下,探讨了该机型金属结构受力的空间传递分配规律,推导出内力计算公式。本文针对空间桥架内力的传递进行探讨,在一定假定条件下,得出主、副梁及主、端梁间的传递规律。

关键词:铸造起重机,应力, 疲劳强度, 稳定性

Abstract

Casting six beams overhead cranes are an important component part of the medium and large lifting equipment, by the four main girder beams and two-component, the design based on the partial tracks box girder, the design process from the strength, stiffness, Stability three aspects, for the working-level A7 crane will run for calibration. This and the following working-level A6 crane design with vastly different, in the design when there are large static strength of the surplus in the calculation of regional stability but also to the partial pressure of the round, This needs time checking STIFFENER checking the grid, is likely to be checked again. The structure of the crane is composed of the primary centrol girder, the assistant centrol girder, the primary dead-end girder and the assistant dead-end girder according to the trait of the crane. On the advance of the intensity, rigidity and structure supporting the load is studied mainly. At the same time we also include the formulate which is used to calculate the internal force. Some kinds of conditions are assured in order to hold the internal relation between them.

Key words: rigidity, intensity, fatigue strength, stability

目录

摘要 II

Abstract III

前言 IV

第一章 总体方案设计 - 1 -

§1.1 原始参数 - 1 -

§1.2总体结构及设计 - 1 -

§1.3 材料选择及许用应力 - 1 -

§1.4各部件尺寸及截面性质 - 2 -

第二章 桥架分析 - 10 -

§2.1 载荷组合的确定 - 10 -

§2.2 桥架假定 - 10 -

§2.3 载荷计算 - 10 -

§2.4简化模型 - 18 -

§2.5 垂直载荷 - 19 -

§2.6 水平载荷 - 22 -

第三章 主主梁计算 - 27 -

§3.1 强度校核 - 27 -

§3.2 主主梁疲劳强度校核 - 28 -

§3.3 主梁的稳定性 - 30 -

§3.4 刚度计算 - 35 -

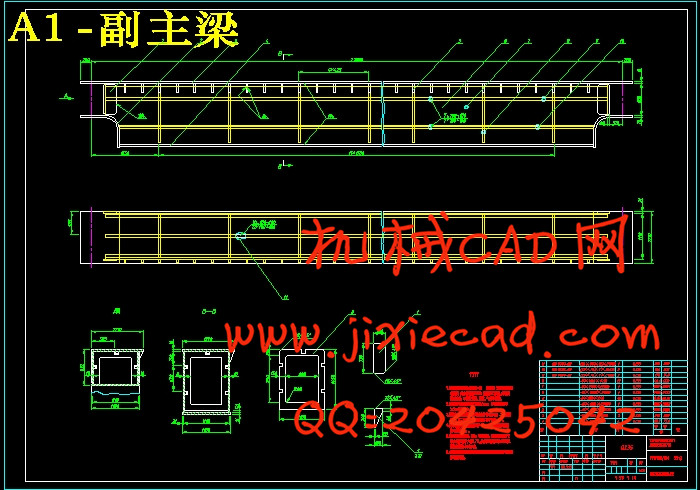

第四章 副主梁校核 - 38 -

§4.1 强度校核 - 38 -

§4.2 副主梁疲劳强度校核 - 39 -

§4.3 副主梁的稳定性 - 41 -

§4.4 刚度计算 - 44 -

§4.5 桥架拱度 - 46 -

第五章 端梁校核 - 48 -

§5.1 主主梁端部耳板设计 - 48 -

§5.2 副主梁一侧端梁的校核 - 51 -

致谢 - 57 -

参考文献 - 58 -

附录A - 59 -

附录B - 65 -

六梁铸造起重机是桥式起重机的重要组成部分,是中大型起重设备,由四根主梁和两根端梁组成。本设计采用偏轨箱型主梁,设计过程中从强度、刚度、稳定性三个方面来计算,对于A7工作级别的起重机来说还要进行疲劳强度校核,这就和A6以下工作级别的起重机的设计有了很大的区别,在设计时会出现静强度有很大的富余,在计算局部稳定性的时候还要注意局部轮压的作用,这时候需要验算加劲肋的区格验算,很有可能需要再次验算。设计中在满足刚度、强度、稳定性的前提下,探讨了该机型金属结构受力的空间传递分配规律,推导出内力计算公式。本文针对空间桥架内力的传递进行探讨,在一定假定条件下,得出主、副梁及主、端梁间的传递规律。

关键词:铸造起重机,应力, 疲劳强度, 稳定性

Abstract

Casting six beams overhead cranes are an important component part of the medium and large lifting equipment, by the four main girder beams and two-component, the design based on the partial tracks box girder, the design process from the strength, stiffness, Stability three aspects, for the working-level A7 crane will run for calibration. This and the following working-level A6 crane design with vastly different, in the design when there are large static strength of the surplus in the calculation of regional stability but also to the partial pressure of the round, This needs time checking STIFFENER checking the grid, is likely to be checked again. The structure of the crane is composed of the primary centrol girder, the assistant centrol girder, the primary dead-end girder and the assistant dead-end girder according to the trait of the crane. On the advance of the intensity, rigidity and structure supporting the load is studied mainly. At the same time we also include the formulate which is used to calculate the internal force. Some kinds of conditions are assured in order to hold the internal relation between them.

Key words: rigidity, intensity, fatigue strength, stability

目录

摘要 II

Abstract III

前言 IV

第一章 总体方案设计 - 1 -

§1.1 原始参数 - 1 -

§1.2总体结构及设计 - 1 -

§1.3 材料选择及许用应力 - 1 -

§1.4各部件尺寸及截面性质 - 2 -

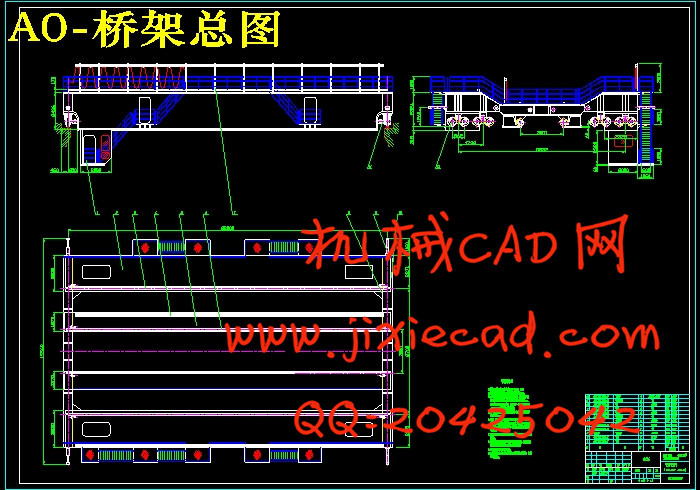

第二章 桥架分析 - 10 -

§2.1 载荷组合的确定 - 10 -

§2.2 桥架假定 - 10 -

§2.3 载荷计算 - 10 -

§2.4简化模型 - 18 -

§2.5 垂直载荷 - 19 -

§2.6 水平载荷 - 22 -

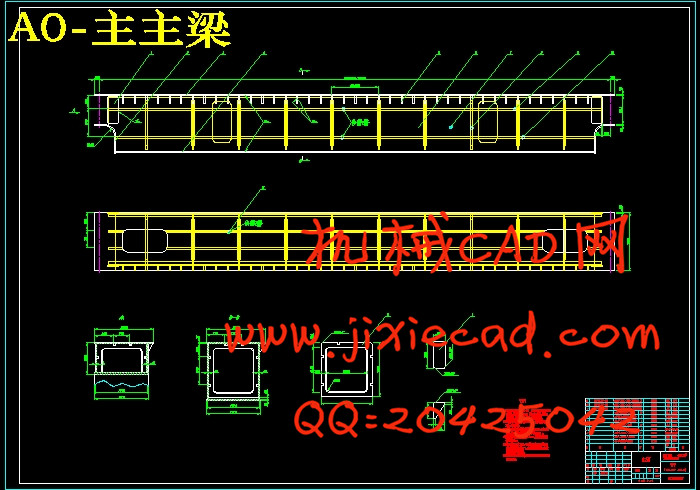

第三章 主主梁计算 - 27 -

§3.1 强度校核 - 27 -

§3.2 主主梁疲劳强度校核 - 28 -

§3.3 主梁的稳定性 - 30 -

§3.4 刚度计算 - 35 -

第四章 副主梁校核 - 38 -

§4.1 强度校核 - 38 -

§4.2 副主梁疲劳强度校核 - 39 -

§4.3 副主梁的稳定性 - 41 -

§4.4 刚度计算 - 44 -

§4.5 桥架拱度 - 46 -

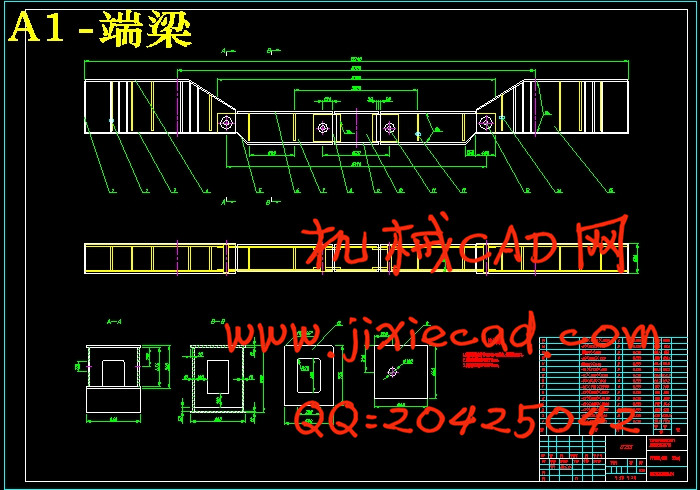

第五章 端梁校核 - 48 -

§5.1 主主梁端部耳板设计 - 48 -

§5.2 副主梁一侧端梁的校核 - 51 -

致谢 - 57 -

参考文献 - 58 -

附录A - 59 -

附录B - 65 -