设计简介

摘要

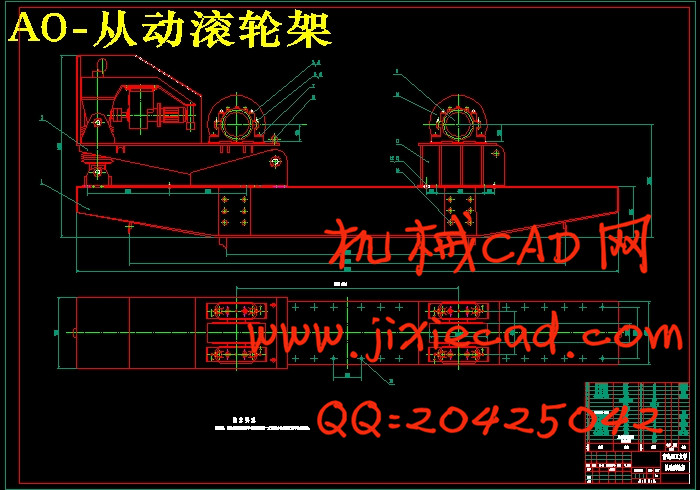

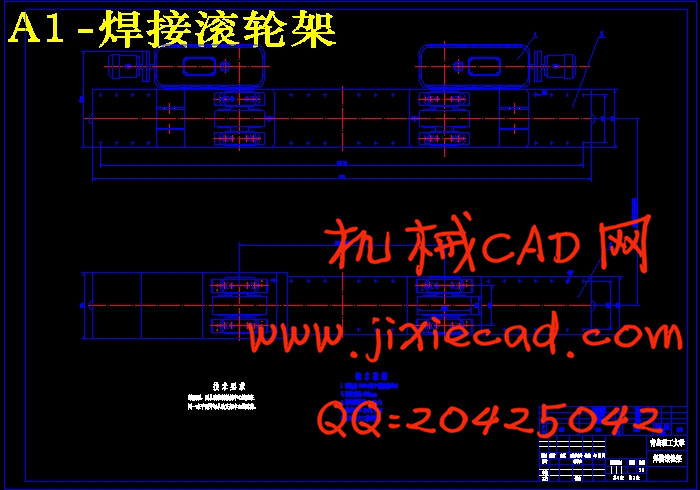

焊接装备就是在焊接生产中与焊接工序相配合,有利于实现焊接生产机械化,自动化,有利于提高装配焊接质量,促使焊接生产过程加速进行的各种辅助装置和设备。焊接滚轮架是借助主动滚轮与焊件之间的摩接力带动焊接旋转的变位机械。文中详细讨论了滚轮架上筒体轴向运动的机理和特性,由于滚轮架制造安装过程中的随机误差,使滚轮与筒体之间产生螺旋角,导致筒体的轴向运动。比较了升降式、平移式和偏转式三种机械调节方式的优缺点,设计中充分的考虑了滚轮架的合理性和经济性等因素。

关键词:焊接;工装夹具;滚轮架

Abstract

Welding equipment is a variety of assistive devices and equipment which in the welding process and welding production line, to the achievement of welding mechanization and automation, and will help improve the quality of welding assembly to speed up the production process of welding. Welding turning rolls is a welding machine by drawing on the wheel and taking the initiative between the Mount Welding relay drive rotating to shift.The mechanism and the characteristics were investigated in detail for the axial drifting of a shaft on the welding turning rolls. The spiral angle that comes from the random errors in the manufacture and the installation of the welding rolls, results in the axial drifting of a cylinder on the welding turning rolls. The comparison was made for both their merits and shortcomings among the three adjusting manners: the elevating, the translational and the deflecting. Fully accounting is taken into in the design of the wheel frame of rationality and economic factors.

Key words: Welding; Tooling Fixture; welding turning rolls

目录

摘要 IAbstract II

目录 III

第1章 绪论 1

1.1 焊接工艺现状及发展方向 1

1.2 论文主要研究内容 2

第2章 焊接用工艺装备 3

2.1 概述 3

2.2 焊接工艺装备 5

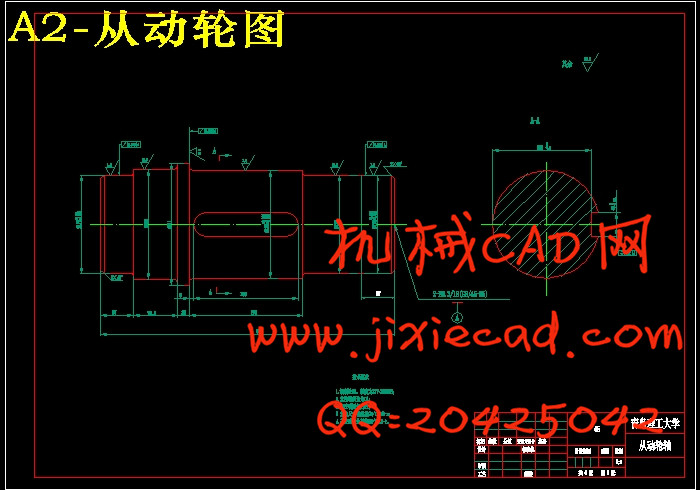

第3章 从动轮设计 9

3.1 中心角的确定 9

3.2 从动轮距设计 10

3.2 从动轮轴设计 10

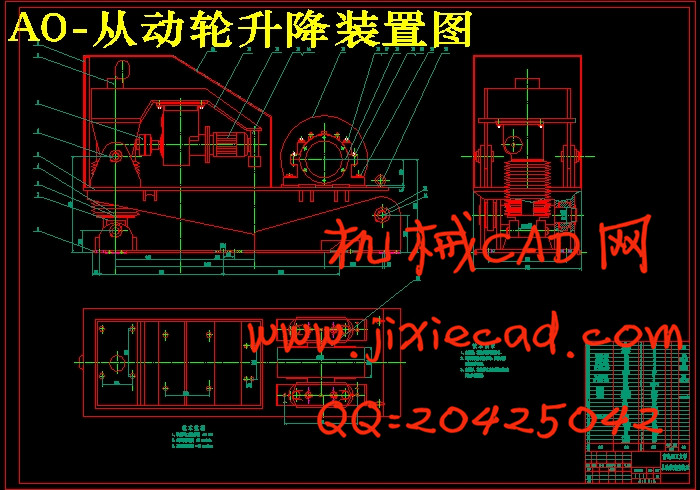

第4章 滚轮架提升装置设计 14

4.1 设计目的 14

4.2 工作原理 14

4.3 方案设计 14

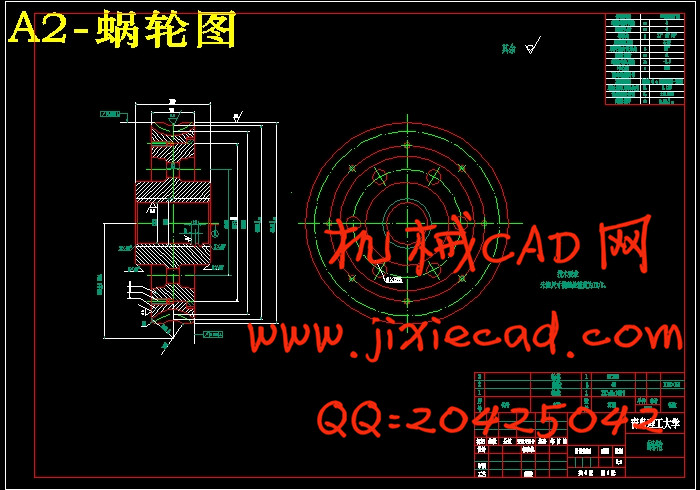

4.4 蜗轮蜗杆减速器设计 18

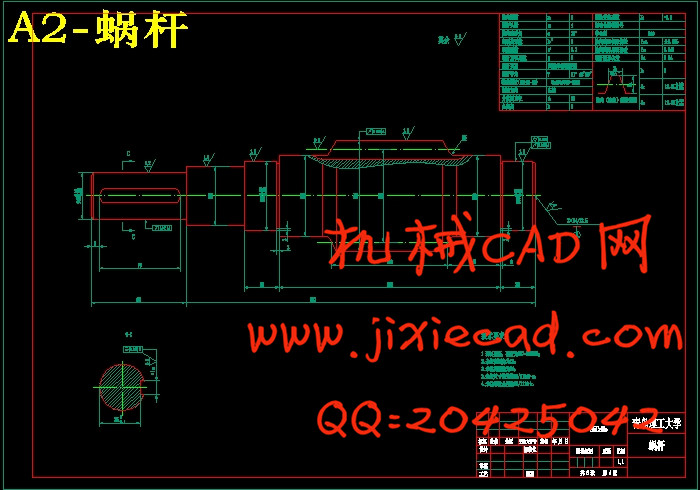

4.5蜗杆设计 21

4.6 部分零件设计 29

结论 30

参考文献 31

致谢 32

附件1 33

附件2 46