设计简介

摘 要

液压传动相对于机械传动来说是一门新技术,液压机是利用帕斯卡定律制成的利用液体压强传动的机械,广泛应用于各种工业中。而在液压机中液压传动系统是其非常重要的组成部分,对液压机的各种性能起到决定性的作用,至于它与微电子和计算机技术密切结合,得以在尽可能小的空间内传递出尽可能大的功率并加以精确控制,更是近几十年内出现的新事物。

本文为5000KN单臂液压机设计了液压传动系统,500T单臂校正压装液压机液压系统采用插装阀集成系统,动作可靠,使用寿命长,液压冲击小,减小了连接管路与泄漏点。独立的电器控制系统,工作可靠,动作直观,维修方便。采用按钮集中控制,设调准(点动),单次(半自动)二种操作方式。大大的提高了传统液压机的控制有欠缺自动化、操纵性和安全性差等缺点。

它适用于轴类零件、型材的校正和轴套类零件的压装、板材零件的弯曲、压印、套形、简单零件的拉伸塑料制品、机床、内燃机、轻纺制造机械、轴类、轴承、洗衣机、汽车电机、空调电机、电器、军工企业、三资企业装配流水线等行业使用。

该设计主要包括在给定参数情况下液压系统零部件的参数计算,从而进行合适的选择,在根据实际情况确定液压元件(辅助元件)以及液压泵站和油箱,文章也附带了液压元件的安装说明及液压机的技术要求和液压机的驱动要求。

关键词:单臂液压机;液压系统 ;液压元件

bstract

液压传动相对于机械传动来说是一门新技术,液压机是利用帕斯卡定律制成的利用液体压强传动的机械,广泛应用于各种工业中。而在液压机中液压传动系统是其非常重要的组成部分,对液压机的各种性能起到决定性的作用,至于它与微电子和计算机技术密切结合,得以在尽可能小的空间内传递出尽可能大的功率并加以精确控制,更是近几十年内出现的新事物。

本文为5000KN单臂液压机设计了液压传动系统,500T单臂校正压装液压机液压系统采用插装阀集成系统,动作可靠,使用寿命长,液压冲击小,减小了连接管路与泄漏点。独立的电器控制系统,工作可靠,动作直观,维修方便。采用按钮集中控制,设调准(点动),单次(半自动)二种操作方式。大大的提高了传统液压机的控制有欠缺自动化、操纵性和安全性差等缺点。

它适用于轴类零件、型材的校正和轴套类零件的压装、板材零件的弯曲、压印、套形、简单零件的拉伸塑料制品、机床、内燃机、轻纺制造机械、轴类、轴承、洗衣机、汽车电机、空调电机、电器、军工企业、三资企业装配流水线等行业使用。

该设计主要包括在给定参数情况下液压系统零部件的参数计算,从而进行合适的选择,在根据实际情况确定液压元件(辅助元件)以及液压泵站和油箱,文章也附带了液压元件的安装说明及液压机的技术要求和液压机的驱动要求。

关键词:单臂液压机;液压系统 ;液压元件

bstract

Hydraulic transmission is a new technology compared with the mechanical transmission. The hydraulic press is based on the Pascal’s law and designed for producing heavy press. The hydraulic drive system is an important part in the hydraulic press system. And it is the fateful element for the techniques of hydraulic press system. When closely combing with microelectronics and computer technology, it is able to deliver as far as possible big power and precise control within as little space as possible, especially in recent years it is a new thing.

This paper is designed for 5000 KN single arm hydraulic press hydraulic transmission system, 500t single arm correction hydraulic press hydraulic system adopts cartridge valve integrated system installation with the advantages to reliable, long service life, small hydraulic impact, reducing the connection pipe and the leak point. The Independent electric control system, has the advantages of the work reliable, intuitive, easy maintenance. With the using of centralized control buttons, alignment (or points) and single (semi-automatic) ,two kinds of operating mode, greatly improve the traditional hydraulic control with lack of automation, poor maneuverability and security flaws.

It is suitable for shaft parts, profile correction and sleeve parts, bending, stamping of sheet parts installation, set of form, the simple components of the tensile plastic products, machine tools, internal combustion engines, textile manufacturing machinery, shaft, bearing, washing machine, automobile motor, air conditioner motor, electrical appliance assembly line, military industrial enterprises, joint ventures, etc.

This design mainly includes the system preliminary design is in such a case that the estimated parameters is determined and the loop forms of some circumstances, hydraulic components and connecting lines are fully determined. The design of the system has the performance analysis and performance checking to deal with the actual situation. I determine hydraulic components (secondary element), and hydraulic pump stations and tank. The article also comes with the installation instructions of hydraulic components and technical requirements of hydraulic press and hydraulic press driven by demand.

Key words: Single arm hydraulic press;Hydraulic system; Hydraulic components

This paper is designed for 5000 KN single arm hydraulic press hydraulic transmission system, 500t single arm correction hydraulic press hydraulic system adopts cartridge valve integrated system installation with the advantages to reliable, long service life, small hydraulic impact, reducing the connection pipe and the leak point. The Independent electric control system, has the advantages of the work reliable, intuitive, easy maintenance. With the using of centralized control buttons, alignment (or points) and single (semi-automatic) ,two kinds of operating mode, greatly improve the traditional hydraulic control with lack of automation, poor maneuverability and security flaws.

It is suitable for shaft parts, profile correction and sleeve parts, bending, stamping of sheet parts installation, set of form, the simple components of the tensile plastic products, machine tools, internal combustion engines, textile manufacturing machinery, shaft, bearing, washing machine, automobile motor, air conditioner motor, electrical appliance assembly line, military industrial enterprises, joint ventures, etc.

This design mainly includes the system preliminary design is in such a case that the estimated parameters is determined and the loop forms of some circumstances, hydraulic components and connecting lines are fully determined. The design of the system has the performance analysis and performance checking to deal with the actual situation. I determine hydraulic components (secondary element), and hydraulic pump stations and tank. The article also comes with the installation instructions of hydraulic components and technical requirements of hydraulic press and hydraulic press driven by demand.

Key words: Single arm hydraulic press;Hydraulic system; Hydraulic components

目

Abstract IV目 录 V

1绪论 1

1.1 液压机的介绍 1

1.1.1液压机的工作原理 1

1.1.2液压机的分类 1

1.2液压形成的技术优点 2

1.3液压传动系统的简介及发展趋势 2

1.3.1 液压传动的概念及其优缺点 2

1.3.2 液压系统的组成 3

1.3.3液压系统的维护 3

1.4本课题的研究内容和意义 4

1.5国内外的发展概况 4

1.6本课题应达到的要求 5

2 5000KN液压系统参数及略见图 6

2.1 表2-1各型号单臂液压机参数(500T) 6

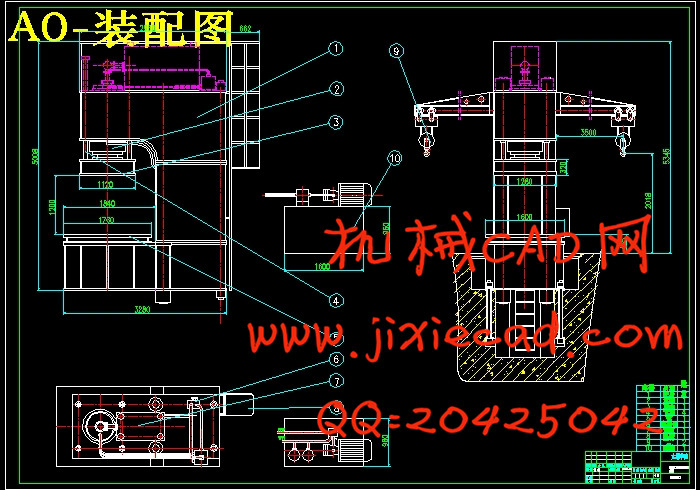

2.2 5000kN单臂液压机(略见图纸) 7

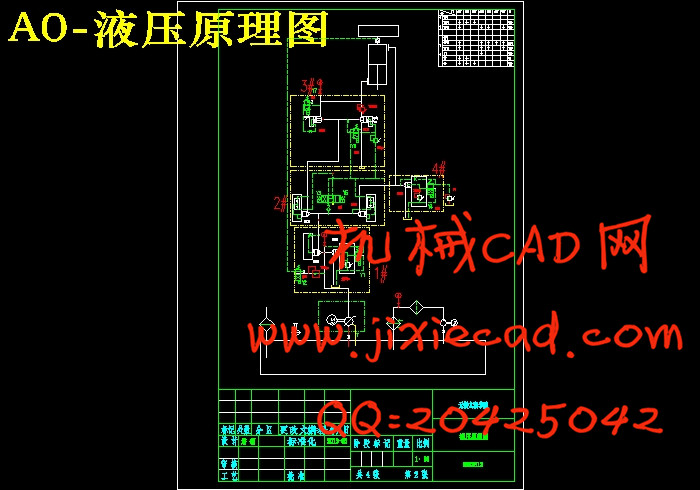

3 单臂液压机液压系统设计 8

3.1 液压系统零部件的参数计算与选择 8

3.1.1 电机的选用 8

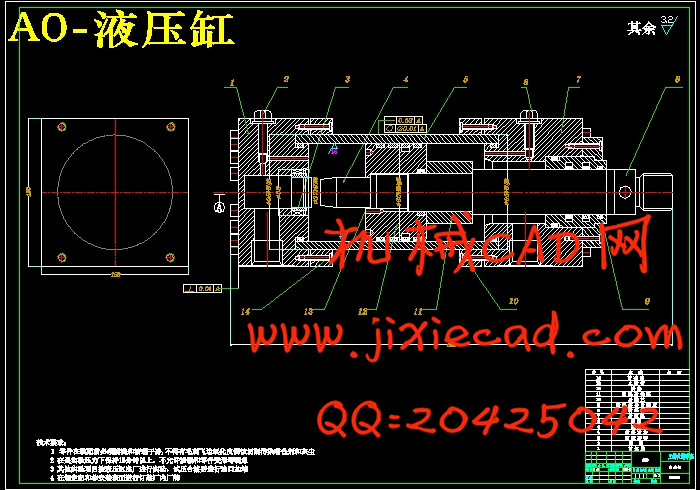

3.1.2 液压缸的载荷组成与计算 8

3.2液压元件的选用 13

3.2.1液压阀的选定 14

3.2.2单向阀的选择 15

3.2.3溢流阀的选择 16

3.2.4电液换向阀的选择 16

3.2.5 电磁换向阀的选择 17

3.2.6顺序阀的选定 17

3.3过滤器的选定 18

3.3.1回油过滤器的选择 18

3.3.2空气过滤器的选择 19

3.4压力表及压力表辅件的选择 19

3.4.1压力表的选定 19

3.4.2压力表开关的选定 20

3.5液位仪表的选定 20

3.6管件的选定 21

3.6.1管路尺寸参数的确定 21

3.6.2管接头的确定 21

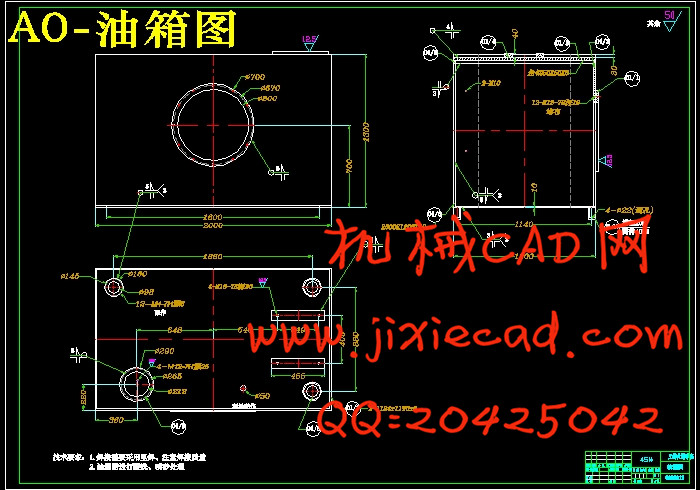

3.7油箱的设计确定 22

3.7.1初选油箱容积 22

3.7.2油箱的结构设计 22

3.8 液压泵站的选用 24

4 液压元件的安装说明和驱动要求 26

4.1 液压元件的安装说明 26

4.2 液压机的安全使用及液压驱动要求 26

4.2.1安全防护 26

4.2.2装配质量 26

4.3 液压驱动要求 27

5 结论与展望 28

5.1 结论 28

5.2不足之处与展望 28

致 谢 30

参考文献 31