设计简介

摘要

AGV全称自动导引小车(Automatic Guided Vehiele),它是在计算机的控制下,经磁或激光等导向装置引导并沿程序设定路径运行完成作业的无人驾驶自动小车,伺服驱动。它为现代制造业、现代物流提供了一种高度柔性化和自动化的运输方式。

目前AGV小车广泛运用在制造业、物流仓储业、汽车、造纸等行业。随着AGV小车的发展,努力设计一个更为合理简便的操作方式的AGV小车,来适用于更多的领域,AGV得到进一步的推广。

AGV是以微控制器为控制核心、蓄电池为动力、装有非接触导引装置的无人驾驶自动导引运载车,其自动作业的基本功能是导向行驶、认址停准和移交载荷。作为当代物流处理自动化的有效手段和柔性制造系统的关键设备,AGV已经得到了越来越广泛的应用,对AGV的研究也具有十分重要的理论意义和现实意义。

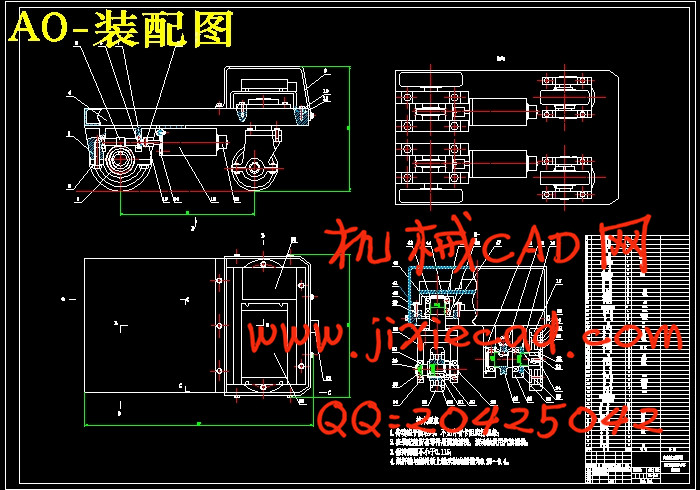

本文介绍了AGV在国内外的发展现状和应用情况,在此基础上,结合毕业设计的课题要求,运用了最为简单的构造模式,前轮由伺服电机、蜗杆涡轮传动,后轮则采用万向轮转动。本文主要进行小车的机械部分设计。

关键词: AGV 连杆机构 轮系结构

ABSTRACT

AGV full automatic guided vehicle ( Automatic Guided Vehiele ), which is under the control of a computer, magnetic or laser guiding device guides and along the programmed path running finish homework unmanned automatic vehicle, servo drive. It is a modern manufacturing industry, modern logistics to provide a highly flexible and automated means of transport.

The AGV dolly is widely used in manufacturing, logistics warehousing, automotive, paper and other industries. With the development of AGV dolly, an effort to design a more reasonable and simple operation of the AGV car, to apply in more fields, AGV further promotion.

AGV is based on micro controller as control core, battery power, a non contact guidance device of unmanned automatic guided vehicle, the automatic operation is the basic function of guiding, recognizing the address to stop and over load. As the valid measure of contemporary logistics processingautomation and the key equipment of flexible manufacture system, AGV has got more and more extensive application, research on AGV has very important theory significance and the practical significance.

This paper introduces the AGV in the domestic and foreign development status and application situation, on this foundation, combining the subject of graduation design requirements, using the most simple structure pattern by the servo motor, front wheel, rear wheel turbine worm driving, the universal wheel. The main car mechanical part design.

Key words: AGV; Connecting rod mechanism; train structure

目 录

摘 要 ……………………………………………………….5

第一章 绪论…………………………………………7

1.1概述…………………………………………………………7

1.2发展趋势及发展前景………………………………………7

1.3AGV系统的构成与AGV的结构…………………………….8

1.3.1AGV系统的构成………………………………………….8

1.3.2AGV的结构……………………………………………….9

第二章 设计任务……………………………………11

2.1设计题目:AGV小车的转向总承设计…………………….11

2.2设计背景:………………………………………………….11

2.2.1题目简述………………………………………………….11

2.2.2使用状况………………………………………………….11

2.2.3生产状况………………………………………………….11

2.3设计参数..………………………………………………….11

2.4设计任务..………………………………………………….11

第三章 AGV机械结构和驱动转向系统的设计………12

3.1AGV机械结构的设计..……………………………………….13

3.1.1车体尺寸结构设计……………………………………….13

3.1.2驱动方式选择…………………………………………….13

3.2驱动系统部件的选择与校核……………………………….14

3.2.1电机的选择与联轴器的选用…………………………….14

3.2.2AGV行驶阻力的计算………………………………………14

3.3主减速比的选择…………………………………………….16

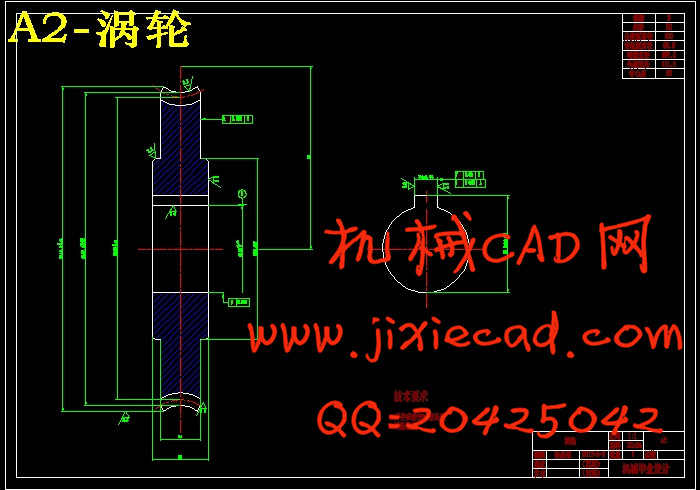

3.4蜗杆蜗轮的设计…………………………………………….17

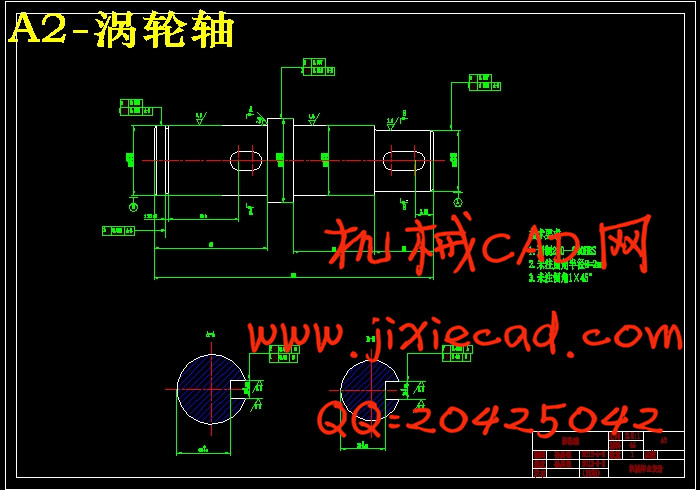

3.5涡轮轴的设计……………………………………………….20

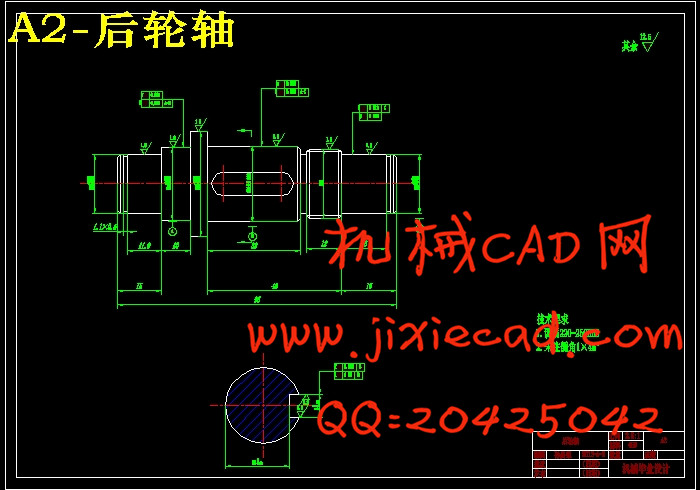

3.6后轮轴的设计……………………………………………….22

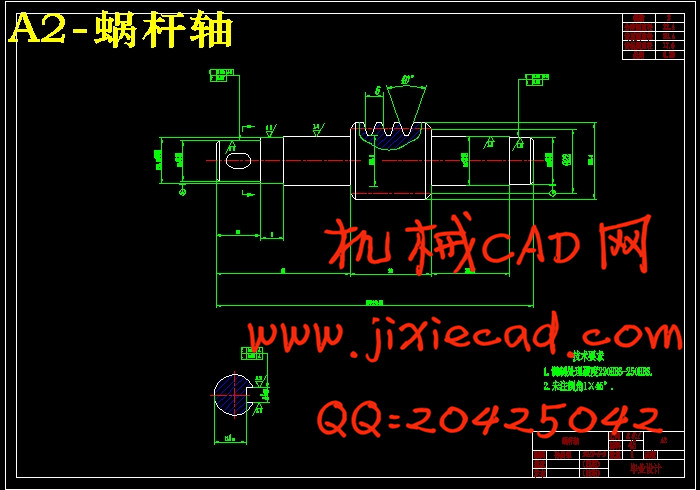

3.7蜗杆轴的设计……………………………………………….24

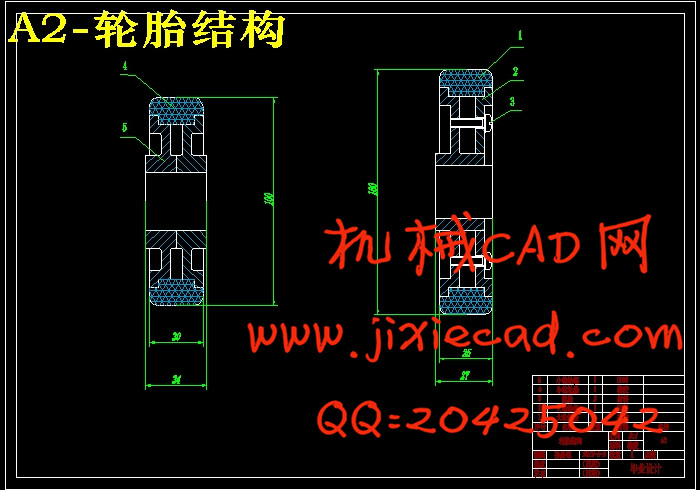

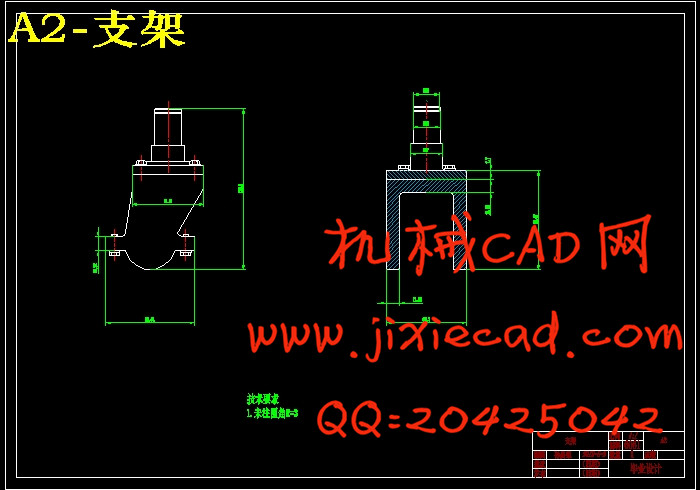

3.8车轮支架的设计…………………………………………….25

第四章 总结………………………………………….27

致谢……………………………………………………………….28

参考文献………………………………………………………….29