设计简介

摘 要

随着我国近几年经济的高速发展,国内的饲料机械技术在科学创新方面有了突飞猛进的发展。例如,牧羊集团和正昌集团他们是我国饲料机械发展最快的企业,他们的技术不仅引领全国,还可与先进国家技术相媲美。此次的毕业设计是以现有制粒设备为基础,并取长补短,进行了改造和创新,力求设计方案较现有产品在各方面性能都有所提高。现有的技术中,有一种环模制粒机,包括机架和圆筒形的中空环模,环模壁上径向开设有若干模孔,环模一端径向设有进料通道,所述环模经传动系统与动力输八机械相连接,环模内设有至少一个压棍,压棍可转动地安装在压辊固定的机构上,工作时,环模转动,物料从进料通道进入环模内,被环模带动,不断从压辊和环模之间空过,在压辊的挤压之下,物料被从模孔中挤出,被切刀装置切断后形成颗料装的物料;其不足之处在于:这种制料机工作效率低下。然而AHHC520制粒机使制粒效率大幅提高。关键词: 双环模; 制粒机; 有限元

Abstract

Internal and external combination 2-ring mould granulating machine is by powder feed conditioning (plus steam or water), extrusion die hole forming, cutting, cooling dry, crushing, screening, finally meet specific product quality made the request. It will cooperate with good various powder feed compressed into granules, changed the physical properties and feed biochemical performance and improve the feed utilization rate and to feed the applicability. Our feed industry late start, many granulating equipment compared with foreign equally, there is still a gap. Through the visit to feed machinery factory, many manufacturers domestic understanding of existing granulating equipment performance are this certain disadvantages. But along with the rapid development of economy in recent years, domestic feed machinery technology in scientific innovation has a breakneck development. For example, shepherd group and zhengchang group they feed machinery in China is the fastest growing enterprise, their technology not only lead the country, still can match with advanced countries technology. The graduation design based on existing granulating equipment for the foundation, and complement each other, reformation and innovation perpetuallystrive to design scheme is in all aspects of existing products performance is improved. The existing technology, have a kind of ring die granulating machine, including frame and the cylindrical hollow ring ring die wall module, open several model hole radial ring die end, with feeding channel, radial referred by the transmission system ring die with power lost eight mechanical connections, ring die equipped with at least one pressure stick, pressure stick can rotate installed in pressing roller fixed institutions, work, ring die rotating, material from incoming channel into the ring ring die mould, was driven, constantly from pressing roller and ring die, in space between the extrusion pressure roller, under from model hole material being squeezed by cutting knife device, off the material form makings outfit; Its defect lies in: this system feeder low productivity. Yet internal and external combination 2-ring mould granulating machine make granulating efficiency greatly improve.

Keywords: 2-ring mode; Granulating machine; FEA

目 录

摘 要 III

Abstract IV

目 录 V

1 绪论 1

1.1 设计目的和意义 1

1.2 环模制粒机的国内外研究现状 2

1.2.1 国外研究现状 3

1.2.2 国内研究现状 3

2 总体方案设计 6

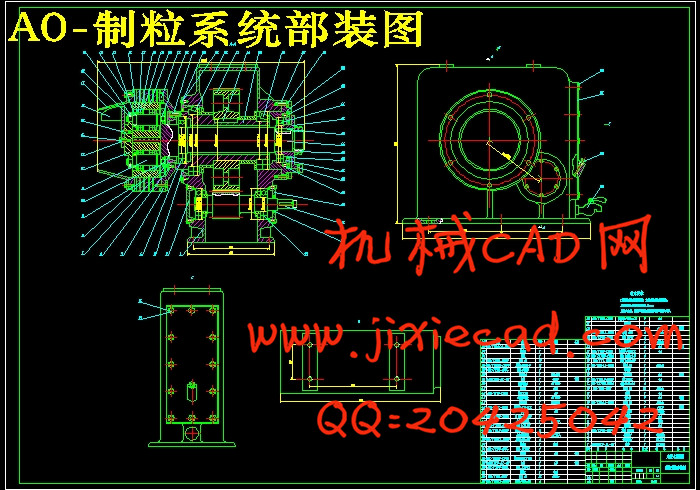

2.1 主要组成结构 6

2.2 主要技术参数 7

2.3 工作原理与工作过程概述 7

2.3.1 环模制粒机的工作原理 7

2.3.2 环模制粒机的主要工作过程 8

3 喂料机构设计 9

3.1 喂料输送结构设计 9

3.2 喂料器参数计算 10

3.2.1 螺旋直径D与螺旋轴转速n的计算 10

3.2.2 物料轴向推进速度计算 10

3.2.3 电机的选择 11

3.3 机槽的设计 11

4 调制器结构设计 12

4.1 调质的作用 12

4.2 调质过程的控制 12

4.3 调制器总体方案设计及计算 12

5 主传动系统的设计 14

5.1主电机的选择 14

5.2 主传动计算 14

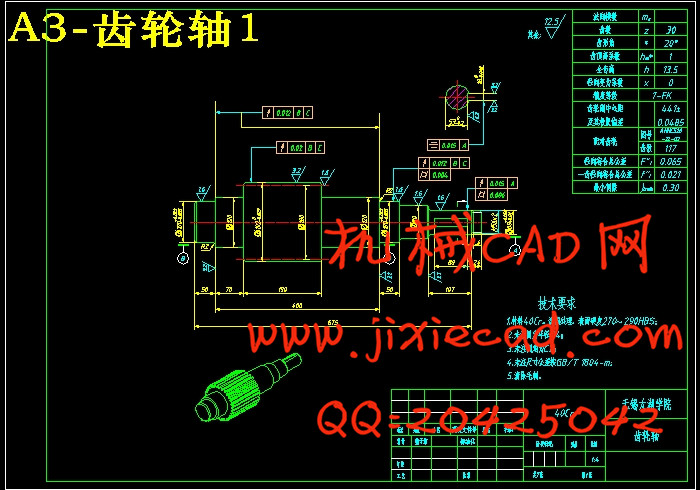

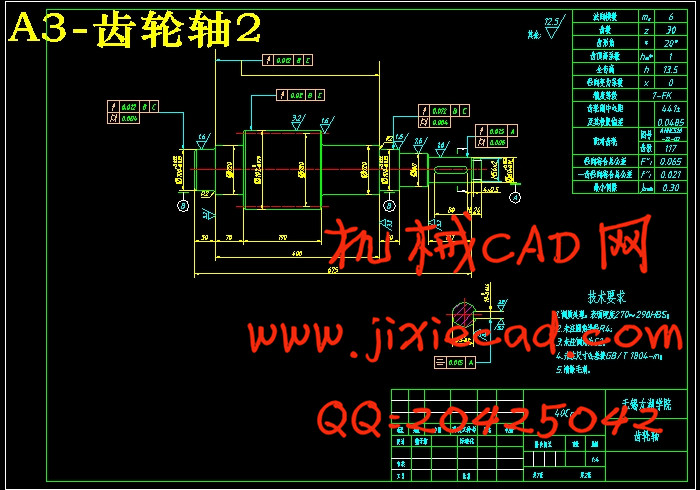

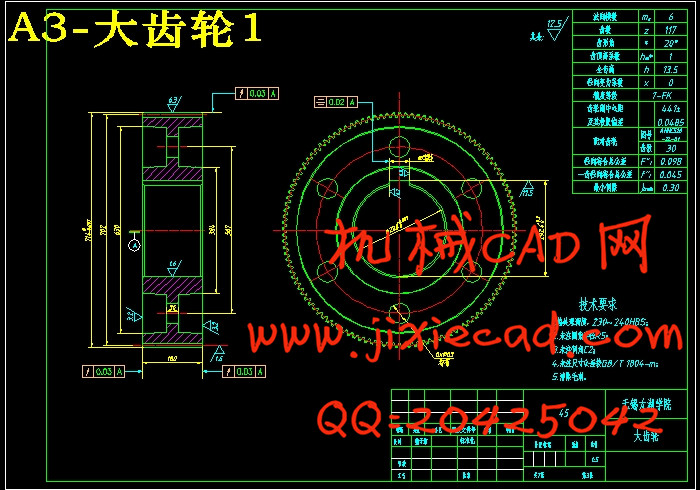

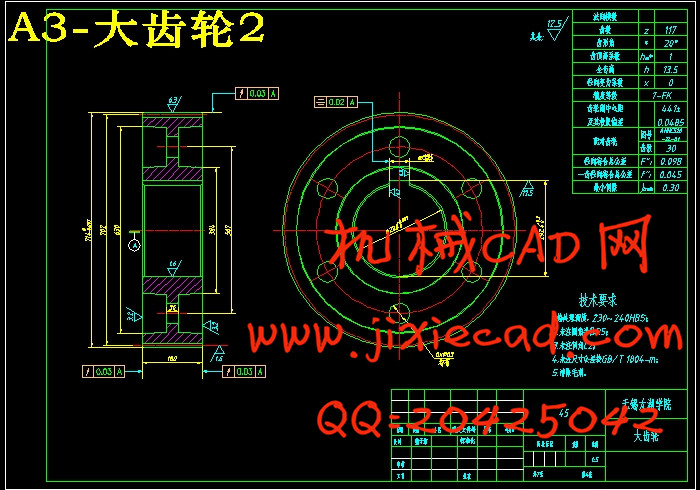

5.2.1 选定齿轮类型、精度等级、材料及齿数 14

5.2.2 按齿面接触强度设计 15

5.2.3 按齿根弯曲强度设计 16

5.2.4 几何尺寸计算 17

5.2.5 结构设计及绘制齿轮零件图 18

5.3 空心轴的有限元分析 18

6 制粒系统的设计与计算 23

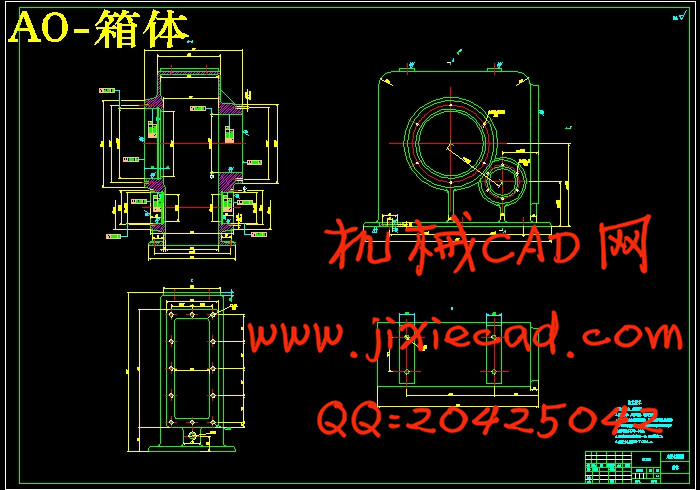

6.1环模的加工工艺综述及结构设计 23

6.1.1 环模的热处理工艺 23

6.1.2 环模模孔的加工工艺 24

6.1.3 环模的结构 24

6.1.4 方案设计 24

6.2 环模的参数计算 24

6.2.1 环模厚度计算 24

6.2.2 环模单位功率面积 25

6.3 压辊的设计计算 25

6.4 环模和压辊工作间隙的调整 25

7 设备拆装及维护 27

7.1 制粒机的使用和维护 27

7.2 制粒机的检修 27

7.2.1 喂料系统拆装 27

7.2.2 主传动系统拆装 28

7.2.3 易损件的拆装 30

结论 33

致谢 34

参考文献 35