设计简介

摘要

中国是一个传统的机械制造大国,但其装备水平落后,特别是一些老机械制造厂大多还是比较旧的机床,远远不能满足加工的要求。

针对目前制业的技术装备现状,对传统机械制造业装备进行改造,解决机械制造业中的些技术问题,用现代先进技术对旧的设备进行改造和提升,是我国制造业的展方向。

本课题是针对己报废的C616普通废旧车床进行数控化改造,现实意义在于如何寻找一种可行的、有推广价值的设备改造方法,对传统机制造行业的技术装备进行技术提升,以解决目前设备老化所带来的问题。

根据数控车床所承担加工任务的特点,其加工的零件类型大多分为轴类套类、盘类等,依据成组工艺技术的原理,我们提出首先编写各类零件成组艺,依据成组工艺,编写数控程序,将数控加工程序编号存入PC机中的方法完成对零件的快速程序编制,提高生产效率。

通过这种方法,可以变小批生为“大”批生产,可以有效的提高生产效率,同时降低对操作人员的要求。

关键字:机床改造, 数控技术, 数控机床,自动刀架

Abstract

China is a traditional mechanical manufacturing country, but the level of their equipment behind, especially in some of the old machinery factory most of the older machines still far from meeting the requirements of processing.

For the current status of technology and equipment manufacturing industry, the traditional machinery manufacturing equipment to transform, to solve some technical machinery manufacturing industry in question the old with modern advanced technology to transform and upgrade the equipment, is the development direction of China's manufacturing industry.

This topic has been scrapped for the C616 is a general transformation of used CNC lathe, practical significance is how to find a feasible and promote the value of the equipment modification method, the traditional machine manufacturing industry, technology and equipment for technical upgrading, to address the current equipment the aging problem.

CNC lathe processing according to the task undertaken by the characteristics of most of its processing of the part type is divided into shaft sleeve, plate etc., based on the principles of group technology, we propose the preparation of various components into a first group of Arts, based on group technology, the preparation of NC program, NC program code stored in the PC, a method of rapid completion of the part programming, improve production efficiency.

In this way, can change a small group of students as "large" batch, can effectively increase productivity, while reducing demands on the operator.

Key word: Transformation tools, numerical control technology, CNC machine tools, automatic knife

目录

一、绪论………………………………………………………………1

(一)数控设备与技术现状……………………………………………2

(二)数控技术……………………………………………4

(三)对我国数控技术和产业化发展的战略思考………………11

(四)设备数控化改造的现状…………………………………………12

(五)本文的选题及主要研究内容……………………………13

二、 西门子802S数控系统介绍……………………………………15

(一)西门子802S数控系统的基本功能………………………15

(二)系统配置方案研究……………………………………15

三、 控制电路设计……………………………………………………18

(一)电路设计…………………………………………………………18

(二)X、Z轴限位和参考点返回电路…………………………………18

(三)机床参数设置……………………………………………………24

(四)控制元件清单…………………………………………………….24

(五)控制电路安装接线图……………………………………………26

四、 数控车床总体改造方案及机械部分设计……………………27

(一)设计要求………………………………………………………27

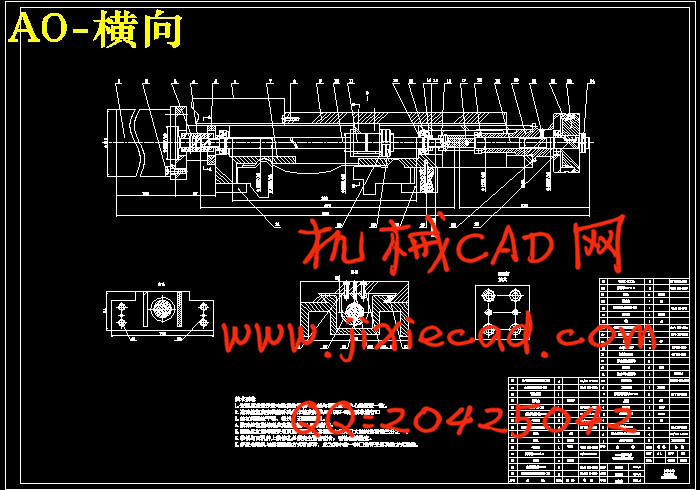

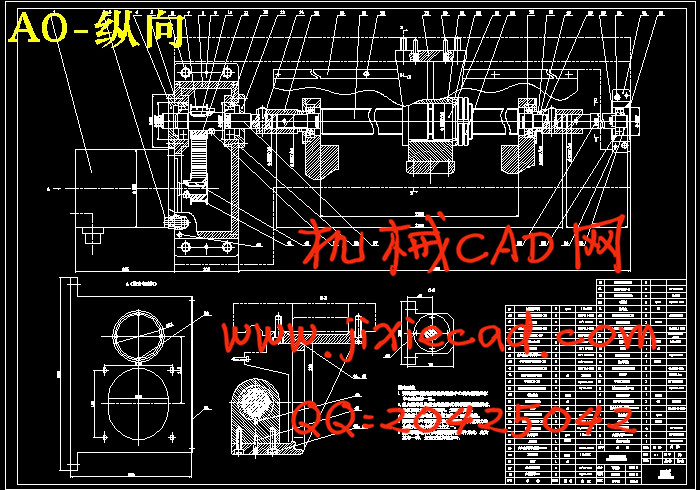

(二)改造方案的确定………………………………………………28

(三)传动系统改装设计与计算……………………………………29

(四)步进电动机的选择……………………………………………37

(五)电动刀架的选择…………………………………………………38

五、 数控机床操作…………………………………………………39

(一)数控机床操作指南………………………………………………39

六、 应用效果………………………………………………………45

(一)应用前景分析……………………………………………………45

(二)经济效益分析……………………………………………………45

结论……………………………………………………………………47

致谢……………………………………………………………………48

参考文献………………………………………………………………49

中国是一个传统的机械制造大国,但其装备水平落后,特别是一些老机械制造厂大多还是比较旧的机床,远远不能满足加工的要求。

针对目前制业的技术装备现状,对传统机械制造业装备进行改造,解决机械制造业中的些技术问题,用现代先进技术对旧的设备进行改造和提升,是我国制造业的展方向。

本课题是针对己报废的C616普通废旧车床进行数控化改造,现实意义在于如何寻找一种可行的、有推广价值的设备改造方法,对传统机制造行业的技术装备进行技术提升,以解决目前设备老化所带来的问题。

根据数控车床所承担加工任务的特点,其加工的零件类型大多分为轴类套类、盘类等,依据成组工艺技术的原理,我们提出首先编写各类零件成组艺,依据成组工艺,编写数控程序,将数控加工程序编号存入PC机中的方法完成对零件的快速程序编制,提高生产效率。

通过这种方法,可以变小批生为“大”批生产,可以有效的提高生产效率,同时降低对操作人员的要求。

关键字:机床改造, 数控技术, 数控机床,自动刀架

Abstract

China is a traditional mechanical manufacturing country, but the level of their equipment behind, especially in some of the old machinery factory most of the older machines still far from meeting the requirements of processing.

For the current status of technology and equipment manufacturing industry, the traditional machinery manufacturing equipment to transform, to solve some technical machinery manufacturing industry in question the old with modern advanced technology to transform and upgrade the equipment, is the development direction of China's manufacturing industry.

This topic has been scrapped for the C616 is a general transformation of used CNC lathe, practical significance is how to find a feasible and promote the value of the equipment modification method, the traditional machine manufacturing industry, technology and equipment for technical upgrading, to address the current equipment the aging problem.

CNC lathe processing according to the task undertaken by the characteristics of most of its processing of the part type is divided into shaft sleeve, plate etc., based on the principles of group technology, we propose the preparation of various components into a first group of Arts, based on group technology, the preparation of NC program, NC program code stored in the PC, a method of rapid completion of the part programming, improve production efficiency.

In this way, can change a small group of students as "large" batch, can effectively increase productivity, while reducing demands on the operator.

Key word: Transformation tools, numerical control technology, CNC machine tools, automatic knife

目录

一、绪论………………………………………………………………1

(一)数控设备与技术现状……………………………………………2

(二)数控技术……………………………………………4

(三)对我国数控技术和产业化发展的战略思考………………11

(四)设备数控化改造的现状…………………………………………12

(五)本文的选题及主要研究内容……………………………13

二、 西门子802S数控系统介绍……………………………………15

(一)西门子802S数控系统的基本功能………………………15

(二)系统配置方案研究……………………………………15

三、 控制电路设计……………………………………………………18

(一)电路设计…………………………………………………………18

(二)X、Z轴限位和参考点返回电路…………………………………18

(三)机床参数设置……………………………………………………24

(四)控制元件清单…………………………………………………….24

(五)控制电路安装接线图……………………………………………26

四、 数控车床总体改造方案及机械部分设计……………………27

(一)设计要求………………………………………………………27

(二)改造方案的确定………………………………………………28

(三)传动系统改装设计与计算……………………………………29

(四)步进电动机的选择……………………………………………37

(五)电动刀架的选择…………………………………………………38

五、 数控机床操作…………………………………………………39

(一)数控机床操作指南………………………………………………39

六、 应用效果………………………………………………………45

(一)应用前景分析……………………………………………………45

(二)经济效益分析……………………………………………………45

结论……………………………………………………………………47

致谢……………………………………………………………………48

参考文献………………………………………………………………49