设计简介

摘 要

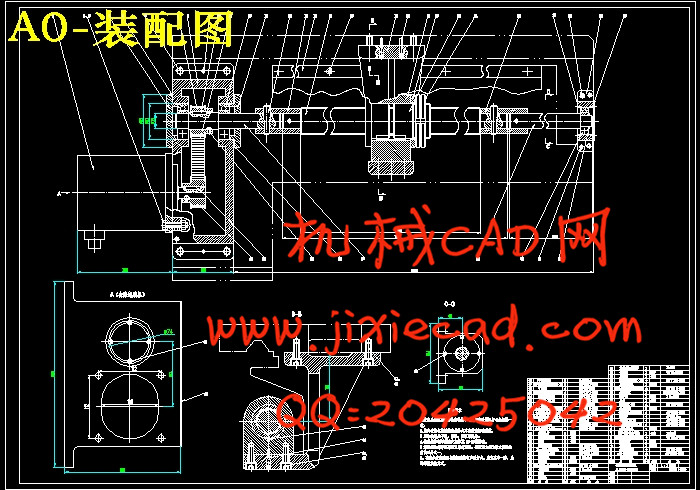

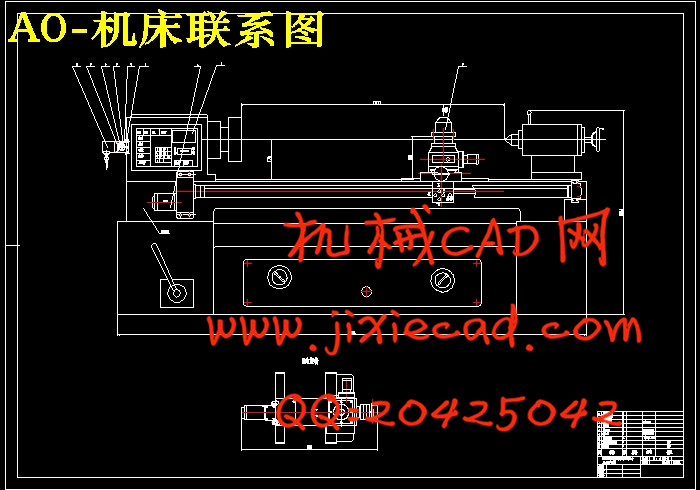

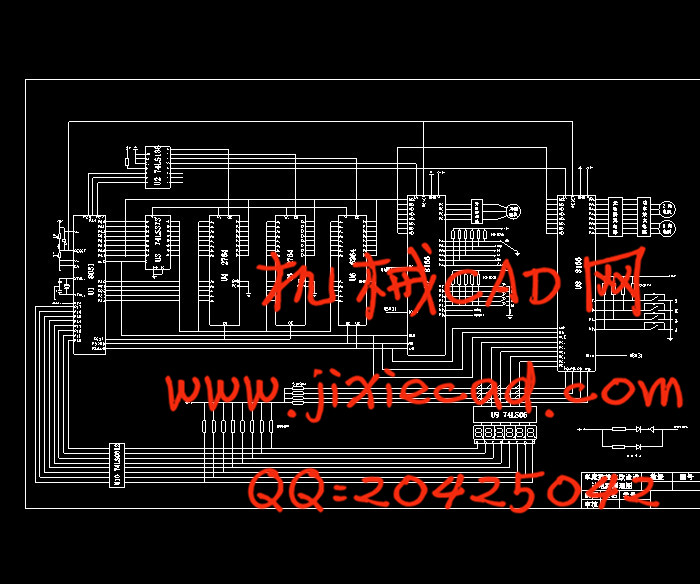

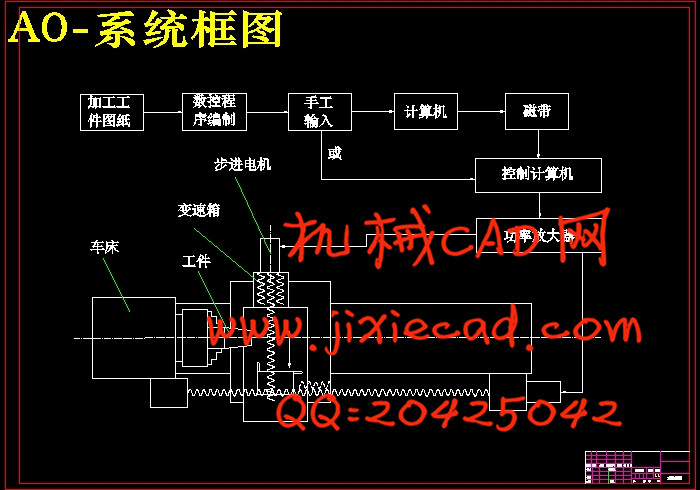

本次设计是对普通车床C6132的数控化改造。在这里主要包括:主传动系统的改造、纵向进给系统的改造、横向进给系统的改造。而我主要是针对纵向进给系统进行机械改造。这次设计对设计工作的基本技能的训练,提高了分析和解决工程技术问题的能力,并为进行一般机械的设计创造了一定条件。

数控改造主要传动系统的机械改造。由于对经济型数控机床的加工精度要求不高,为简化结构、降低成本。通过控制横进给系统,保证改造后的车床具有定位、直线插补、圆弧插补、暂停等功能。为实现机床所要求的传动效率,采用步进电机经联轴器再传动丝杠;为保证一定的传动精度和平稳性,尽量减小摩擦力,选用滚珠丝杠螺母副。

关键词:车床 数控改造 联轴器 滚珠丝杠

Abstract

This design is about the common Lathe C6132 transformation of NC. Main tasks are: the transformation of the main transmission system, the transformation of the vertical feeding system, horizontal feed system reform. While I was mainly aim at the lateral feeding system mechanical transformation. The graduation project on the design of the basic skills training has improved the analysis and the ability to solve engineering problems, and create a certain condition for general mechanical design.

NC transformation is mainly a transformation of mechanical drive system. Because of the economy less precision CNC machining, it is order to simplify the structure and reduce costs. By controlling the cross-feed system, it ensures the modified lathe with positioning, linear interpolation, circular interpolation, and pause. Required for the realization of the transmission efficiency of machine tool, we should us a stepping motor drive and then screw through the coupling. To ensure a certain degree of driving accuracy and stability and minimize friction, a ball screw pair is needed.

Keywords: lathe, NC Transformation , Coupling ,Ball Screw

目录

一、前言 …………………………………………………………………… 1

二、设计任务 ………………………………………………………………1

三.总体方案的确定 ……………………………………………………1

四、机械传动方案的分析与计算 ………………………………………1

(一)脉冲当量的确定 ………………………………………………………1

(二)切削力的计算 …………………………………………………………2

(三)纵传动系统的分析与计算(Z轴方向) ……………………………2

1.滚珠丝杠螺母副的计算与选型(纵向) ……………………………… 2

2、减速箱的设计(纵向)………………………………………………… 4

3、步进电动机的计算与选型(纵向) …………………………………… 6

4、同步带传送功率的校核(纵向) ……………………………………… 9

(四)纵向传动系统的分析与计算(X轴方向) ………………… 10

1、滚珠丝杠螺母副的计算与选型(横向) ……………………………… 10

2、减速箱的设计(横向) ……………………………………………… 12

3、步进电动机的计算与选型(横向)…………………………………… 12

本次设计是对普通车床C6132的数控化改造。在这里主要包括:主传动系统的改造、纵向进给系统的改造、横向进给系统的改造。而我主要是针对纵向进给系统进行机械改造。这次设计对设计工作的基本技能的训练,提高了分析和解决工程技术问题的能力,并为进行一般机械的设计创造了一定条件。

数控改造主要传动系统的机械改造。由于对经济型数控机床的加工精度要求不高,为简化结构、降低成本。通过控制横进给系统,保证改造后的车床具有定位、直线插补、圆弧插补、暂停等功能。为实现机床所要求的传动效率,采用步进电机经联轴器再传动丝杠;为保证一定的传动精度和平稳性,尽量减小摩擦力,选用滚珠丝杠螺母副。

关键词:车床 数控改造 联轴器 滚珠丝杠

Abstract

This design is about the common Lathe C6132 transformation of NC. Main tasks are: the transformation of the main transmission system, the transformation of the vertical feeding system, horizontal feed system reform. While I was mainly aim at the lateral feeding system mechanical transformation. The graduation project on the design of the basic skills training has improved the analysis and the ability to solve engineering problems, and create a certain condition for general mechanical design.

NC transformation is mainly a transformation of mechanical drive system. Because of the economy less precision CNC machining, it is order to simplify the structure and reduce costs. By controlling the cross-feed system, it ensures the modified lathe with positioning, linear interpolation, circular interpolation, and pause. Required for the realization of the transmission efficiency of machine tool, we should us a stepping motor drive and then screw through the coupling. To ensure a certain degree of driving accuracy and stability and minimize friction, a ball screw pair is needed.

Keywords: lathe, NC Transformation , Coupling ,Ball Screw

目录

一、前言 …………………………………………………………………… 1

二、设计任务 ………………………………………………………………1

三.总体方案的确定 ……………………………………………………1

四、机械传动方案的分析与计算 ………………………………………1

(一)脉冲当量的确定 ………………………………………………………1

(二)切削力的计算 …………………………………………………………2

(三)纵传动系统的分析与计算(Z轴方向) ……………………………2

1.滚珠丝杠螺母副的计算与选型(纵向) ……………………………… 2

2、减速箱的设计(纵向)………………………………………………… 4

3、步进电动机的计算与选型(纵向) …………………………………… 6

4、同步带传送功率的校核(纵向) ……………………………………… 9

(四)纵向传动系统的分析与计算(X轴方向) ………………… 10

1、滚珠丝杠螺母副的计算与选型(横向) ……………………………… 10

2、减速箱的设计(横向) ……………………………………………… 12

3、步进电动机的计算与选型(横向)…………………………………… 12