设计简介

摘要

车床主要是为了进行车外圆、车端面和镗孔等项工作而设计的机床。车削很少在其他种类的机床上进行,而且任何一种其他机床都不能像车床那样方便地进行车削加工。由于车床还可以用来钻孔和铰孔,车床的多功能性可以使工件在一次安装中完成几种加工。因此,在生产中使用的各种车床比任何其他种类的机床都多。车床的基本部件有:床身、主轴箱组件、尾座组件、溜板组件、丝杠和光杠。

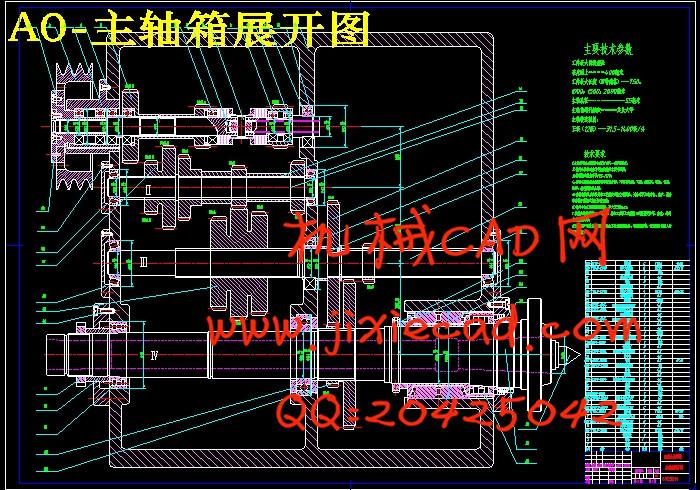

主轴箱安装在内侧导轨的固定位置上,一般在床身的左端。它提供动力,并可使工件在各种速度下回转。它基本上由一个安装在精密轴承中的空心主轴和一系列变速齿轮(类似于卡车变速箱)所组成。通过变速齿轮,主轴可以在许多种转速下旋转。大多数车床有8~12种转速,一般按等比级数排列。而且在现代机床上只需扳动2~4个手柄,就能得到全部转速。一种正在不断增长的趋势是通过电气的或者机械的装置进行无级变速。

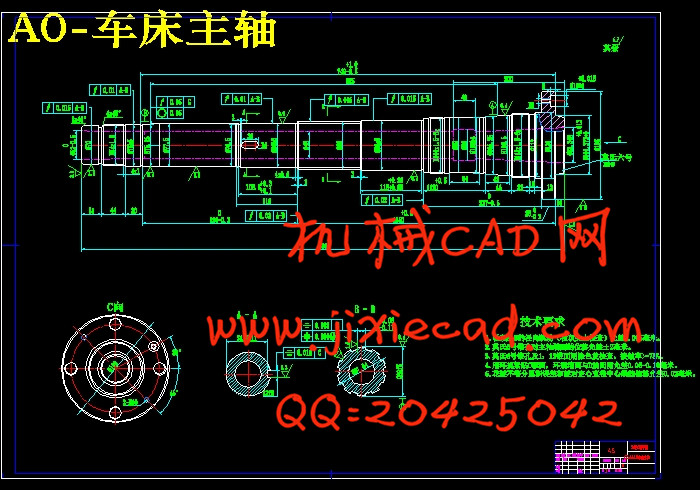

由于机床的精度在很大程度上取决于主轴,因此,主轴的结构尺寸较大,通常安装在预紧后的重型圆锥滚子轴承或球轴承中。主轴中有一个贯穿全长的通孔,长棒料可以通过该孔送料。主轴孔的大小是车床的一个重要尺寸,因此当工件必须通过主轴孔供料时,它确定了能够加工的棒料毛坯的最大尺寸。

关键字:车床;主轴箱组件;主轴;无级变速

Abstract

Lathes are machine tools designed primarily to do turning, facing and boring, Very little turning is done on other types of machine tools, and none can do it with equal facility. Because lathes also can do drilling and reaming, their versatility permits several operations to be done with a single setup of the work piece. Consequently, more lathes of various types are used in manufacturing than any other machine tool.The essential components of a lathe are the bed, headstock assembly, tailstock assembly, and the leads crew and feed rod.

The headstock is mounted in a foxed position on the inner ways, usually at the left end of the bed. It provides a powered means of rotating the word at various speeds . Essentially, it consists of a hollow spindle, mounted in accurate bearings, and a set of transmission gears-similar to a truck transmission—through which the spindle can be rotated at a number of speeds. Most lathes provide from 8 to 18 speeds, usually in a geometric ratio, and on modern lathes all the speeds can be obtained merely by moving from two to four levers. An increasing trend is to provide a continuously variable speed range through electrical or mechanical drives.

Because the accuracy of a lathe is greatly dependent on the spindle, it is of heavy construction and mounted in heavy bearings, usually preloaded tapered roller or ball types. The spindle has a hole extending through its length, through which long bar stock can be fed. The size of maximum size of bar stock that can be machined when the material must be fed through spindle.

Key words: Lathes; headstock assembly; variable speed;

摘要 III

Abstract IV

1 绪论 1

1.1设计的目的 1

1.2机床主传动系统设计要求 1

2 车床参数的拟定 2

2.1车床主参数和基本参数 2

2.1.1极限切削速度Vmax、Vmin的确定 2

2.1.2主轴的极限转速的确定 2

2.1.3主轴转速级数和公比的确定 3

2.1.4主电机的选择 3

3 主传动系统设计 6

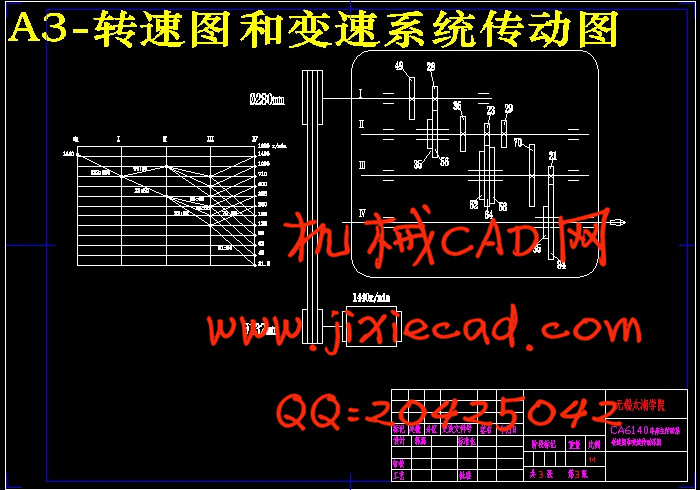

3.1传动结构式、结构网、转速图的确定 6

3.1.1传动形式的确定 6

3.1.2传动组及各传动组中传动副的数目 6

3.1.3 传动系统扩大顺序的安排 7

3.1.4 绘制转速图 7

3.1.5转速图的拟定 7

3.1.6分配降速比 8

3.2 齿轮齿数的确定及传动系统图的绘制 10

3.2.1带轮确定 10

3.2.2齿轮齿数的确定的要求 14

4 强度计算和结构草图设计 17

4.1 确定计算转速 17

4.1.1 各轴、齿轮的计算转速 17

4.2轴的估算和验算 19

4.2.1 主轴的设计与计算 19

4.2.2传动轴直径的估算 22

4.3 齿轮模数的估算和计算 24

4.3.1齿轮模数的估算 24

4.3.2 齿轮模数的验算 26

4.4 轴承的选择与校核 31

4.4.1一般传动轴上的轴承选择 31

4.4.2主轴轴承的类型 31

4.4.3 轴承间隙调整和预紧 33

4.4.4轴承的较核 34

4.4.5 轴承的密封和润滑 36

4.5 片式摩擦离合器的选择与验算 36

4.5.1按扭矩选择 36

4.5.2片式离合器的计算 36

4.5.3计算摩擦面的对数Z 37

5 主轴箱的箱体设计 39

6 结论与展望 40

6.1 结论 40

6.2 展望 40

致 谢 41

参考文献 42