设计简介

摘 要

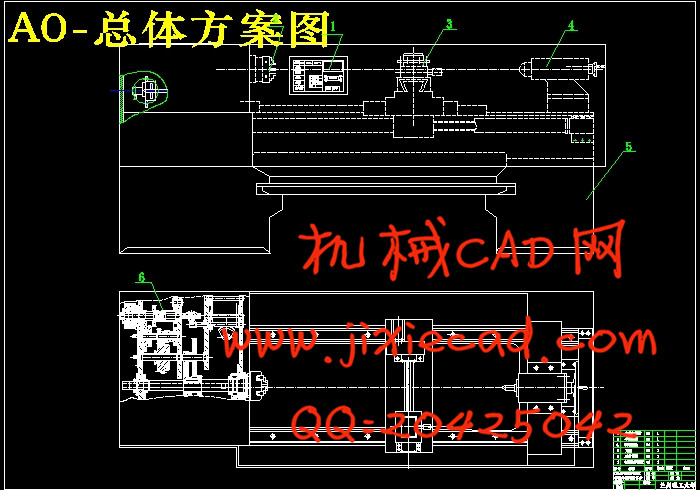

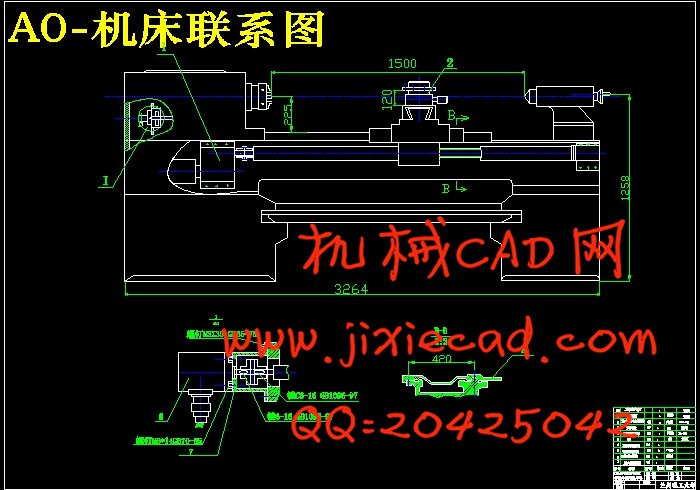

数控机床在机械制造业中发挥着巨大的作用,但数控机床一次性投资较大,对机床进行数控化改造不失为一良策。C6140车床主轴转速部分保留原车床的手动变速功能,改造简单易行,可降低劳动强度,提高生产效率。主要介绍了经济型数控机床进给(纵向)伺服系统设计计算。阐述了C6140普通数控车床的主轴系统的改进及机床控制系统的改造。

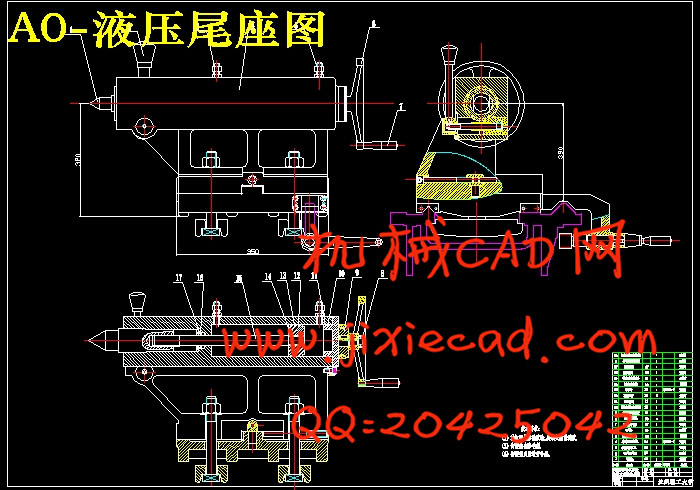

本课题的目的在于设计出与数控卧式车床C6140相匹配的液压尾座系统。本课题将以数控卧式车床C6140的液压尾座为研究对象,设计出符合数控卧式车床C6140的液压尾座。

为了完成本课题的设计,在设计之前的准备工作必须做好,首先是搜集和分析资料,包括国内外数控机床的发展现状及趋势;液压技术和液压传动系统的基本资料;同等机床液压尾座的图纸和资料等。其次是初步确定液压尾座的总体布局,包括配置形式、液压系统的布置及选择液压能源及相应的配套元件等。最后主要是关于尾座的设计。

C6140数控机床液压尾座设计的主要内容是尾座体、套筒、顶尖、尾座孔系、尾座导轨,挠度、转角、液压缸内径及压板处螺栓直径、锁紧力的计算及校核。其中选择莫氏4号锥度的尾座顶尖,是利用莫氏锥度自身的结构特性来卡紧尾座顶尖的,它解决了顶尖在工作时会出现松动或转动现象。在套筒中设计了滑键槽和顶尖顶出孔,解决了顶尖在工作时会随套筒转动从而影响工件的加工精度;还在套筒中设计了顶卸的装置,便于顶尖的拆卸。

关键词:C6140车床 数控改造 滚珠丝杠 步进电动机 尾座 液压系统 液压缸 设计 校核

Numerical Control Transform of C6140Common Lathe

And Design of C6140 CNC Machine Tailstock Hydraulic System

Abstract

The NC machine plays a verygreat role in mechanical engineering. Although the investment needs a great deal of money, it is a good way to try digital modification for ordinary lathe. The spindle speed of C6140 remains the manual function of shifting gears. The alteration is easy and it can reduce labor intensity and improve productive efficiency. Introduces the design calculation of servo system on economic NC machine tools. It also tells us howto improve the spindle and the control system of C6140 NC lathe.

The main purpose of the research is based on C6140 CNC machine tools to design requirements, designed to match its hydraulic Tailstock to meet the rotation accuracy, rigidity, temperature rise, and so on seismic requirements, to enhance the overall performance of machine tools.

To accomplish this design, I collected and analysed the information before the design, including domestic and international development of CNC machine tools; hydraulic system of hydraulic technology and the basic information; equal hydraulic machine Tailstock the drawings and information . Then is tentatively determined the overall layout of hydraulic Tailstock, including the allocation of form, layout and the hydraulic system of hydraulic energy, and select the appropriate matching components, such as. This was followed by the main Tailstock the design and calculation.

The main design of C6140CNC machine tools is that the tailstock, top and the hole, the tailstock, and they are allowed to produce cantilever deflections corner, hydraulic cylinder bore diameter and pressed the bolt in place, the locking force of the school. One of the nuclear option morse the cone at the end of the top and is using its own structure of the cone morse the nature of the top card up its tail, it addresses the top of the work that is coming loose. The turning or pivoting in the design of cylinder and the top of a punch to the top of the work will turn to the influence of the processing of precision ;It was set in the design of the top of the device to the top down.

Key words:The C6140 lathe; digital modification; ball screw; stepping motor; machine;tailstock;hydraulicsystem;hydraulic cylinder inside diameter;design;examination

目 录

摘要 ………………………………………………………………………………………2

Abstract …………………………………………………………………………………3

绪论 ………………………………………………………………………………………4

第一章C6140车床进给伺服系统改造方案的拟订………………………………………6

1.1 总体方案确定 …………………………………………………………………6

1.2 C6140车床的设计参数…………………………………………………………………… 7

第二章 C6140车床进给伺服系统机械部分设计计算 …………………………………8

2.1进给伺服系统机械部分的改造方案……………………………………………………8

2.2进给伺服机构机械部分的设计计算……………………………………………………9

2.3滚珠丝杠螺母副的计算和选型、校核……………………………………………… 9

2.4纵向及横向滚珠丝杠副几何参数………………………………………………14

2.5齿轮传动比计算……………………………………………………………………… 15

第三章 C6140车床进给部分电机的选择……………………………………16

3.1纵向进给步进电机计算 ………………………………………………………………16

3.2横向进给步进电机计算……………………………………………………………… 19

第四章 液压尾座部分设计………………………………………………………23

4.1 液压尾座研究背景和意义……………………………………………………………… 23

4.2 液压尾座研究背景和意义……………………………………………………………… 23

4.3 液压尾座的设计………………………………………………………………………… 23

4.4 尾座精度设计…………………………………………………………………………… 23

总结………………………………………………………………………………………25

参考文献…………………………………………………………………………………26

致谢………………………………………………………………………………………27

数控机床在机械制造业中发挥着巨大的作用,但数控机床一次性投资较大,对机床进行数控化改造不失为一良策。C6140车床主轴转速部分保留原车床的手动变速功能,改造简单易行,可降低劳动强度,提高生产效率。主要介绍了经济型数控机床进给(纵向)伺服系统设计计算。阐述了C6140普通数控车床的主轴系统的改进及机床控制系统的改造。

本课题的目的在于设计出与数控卧式车床C6140相匹配的液压尾座系统。本课题将以数控卧式车床C6140的液压尾座为研究对象,设计出符合数控卧式车床C6140的液压尾座。

为了完成本课题的设计,在设计之前的准备工作必须做好,首先是搜集和分析资料,包括国内外数控机床的发展现状及趋势;液压技术和液压传动系统的基本资料;同等机床液压尾座的图纸和资料等。其次是初步确定液压尾座的总体布局,包括配置形式、液压系统的布置及选择液压能源及相应的配套元件等。最后主要是关于尾座的设计。

C6140数控机床液压尾座设计的主要内容是尾座体、套筒、顶尖、尾座孔系、尾座导轨,挠度、转角、液压缸内径及压板处螺栓直径、锁紧力的计算及校核。其中选择莫氏4号锥度的尾座顶尖,是利用莫氏锥度自身的结构特性来卡紧尾座顶尖的,它解决了顶尖在工作时会出现松动或转动现象。在套筒中设计了滑键槽和顶尖顶出孔,解决了顶尖在工作时会随套筒转动从而影响工件的加工精度;还在套筒中设计了顶卸的装置,便于顶尖的拆卸。

关键词:C6140车床 数控改造 滚珠丝杠 步进电动机 尾座 液压系统 液压缸 设计 校核

Numerical Control Transform of C6140Common Lathe

And Design of C6140 CNC Machine Tailstock Hydraulic System

Abstract

The NC machine plays a verygreat role in mechanical engineering. Although the investment needs a great deal of money, it is a good way to try digital modification for ordinary lathe. The spindle speed of C6140 remains the manual function of shifting gears. The alteration is easy and it can reduce labor intensity and improve productive efficiency. Introduces the design calculation of servo system on economic NC machine tools. It also tells us howto improve the spindle and the control system of C6140 NC lathe.

The main purpose of the research is based on C6140 CNC machine tools to design requirements, designed to match its hydraulic Tailstock to meet the rotation accuracy, rigidity, temperature rise, and so on seismic requirements, to enhance the overall performance of machine tools.

To accomplish this design, I collected and analysed the information before the design, including domestic and international development of CNC machine tools; hydraulic system of hydraulic technology and the basic information; equal hydraulic machine Tailstock the drawings and information . Then is tentatively determined the overall layout of hydraulic Tailstock, including the allocation of form, layout and the hydraulic system of hydraulic energy, and select the appropriate matching components, such as. This was followed by the main Tailstock the design and calculation.

The main design of C6140CNC machine tools is that the tailstock, top and the hole, the tailstock, and they are allowed to produce cantilever deflections corner, hydraulic cylinder bore diameter and pressed the bolt in place, the locking force of the school. One of the nuclear option morse the cone at the end of the top and is using its own structure of the cone morse the nature of the top card up its tail, it addresses the top of the work that is coming loose. The turning or pivoting in the design of cylinder and the top of a punch to the top of the work will turn to the influence of the processing of precision ;It was set in the design of the top of the device to the top down.

Key words:The C6140 lathe; digital modification; ball screw; stepping motor; machine;tailstock;hydraulicsystem;hydraulic cylinder inside diameter;design;examination

目 录

摘要 ………………………………………………………………………………………2

Abstract …………………………………………………………………………………3

绪论 ………………………………………………………………………………………4

第一章C6140车床进给伺服系统改造方案的拟订………………………………………6

1.1 总体方案确定 …………………………………………………………………6

1.2 C6140车床的设计参数…………………………………………………………………… 7

第二章 C6140车床进给伺服系统机械部分设计计算 …………………………………8

2.1进给伺服系统机械部分的改造方案……………………………………………………8

2.2进给伺服机构机械部分的设计计算……………………………………………………9

2.3滚珠丝杠螺母副的计算和选型、校核……………………………………………… 9

2.4纵向及横向滚珠丝杠副几何参数………………………………………………14

2.5齿轮传动比计算……………………………………………………………………… 15

第三章 C6140车床进给部分电机的选择……………………………………16

3.1纵向进给步进电机计算 ………………………………………………………………16

3.2横向进给步进电机计算……………………………………………………………… 19

第四章 液压尾座部分设计………………………………………………………23

4.1 液压尾座研究背景和意义……………………………………………………………… 23

4.2 液压尾座研究背景和意义……………………………………………………………… 23

4.3 液压尾座的设计………………………………………………………………………… 23

4.4 尾座精度设计…………………………………………………………………………… 23

总结………………………………………………………………………………………25

参考文献…………………………………………………………………………………26

致谢………………………………………………………………………………………27