设计简介

摘要

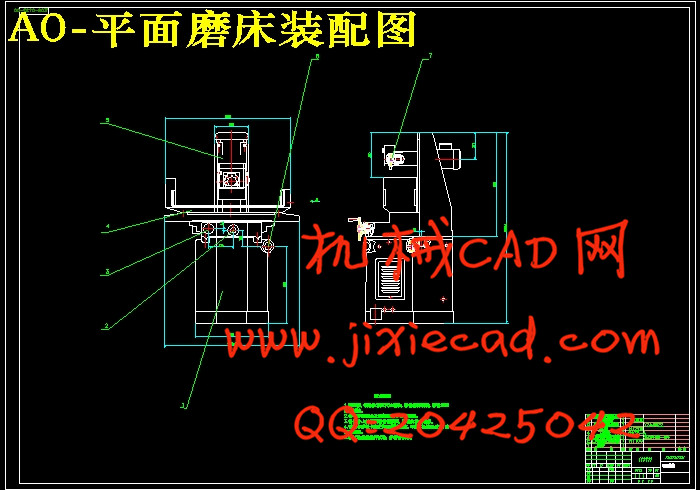

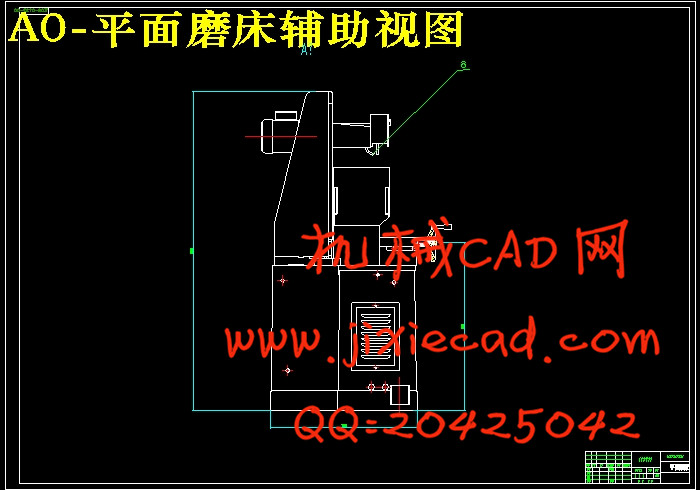

本设计以HZ-64和HZ-1642型平面磨床为例,对平面磨床验收、使用与维护规程的研究与制订。根据磨床在机械制造行业的性能要求,对平面磨床进行规范验收、正确使用与合理维护规程的研究与制订。平面磨床是常用的金属加工平面磨床,在机械制造企业大量使用。平面磨床使用期限的长短,生产效率和工作精度的高低,在很大程度上取决于它的验收、使用与维护情况。本课题主要包含以下内容:各类磨床简介;平面磨床简介;平面磨的验收;平面磨床的安装;平面磨床的使用规程;平面磨床的维护;平面磨床的检修;部分平面磨床零部件的测绘与润滑图表的绘制。

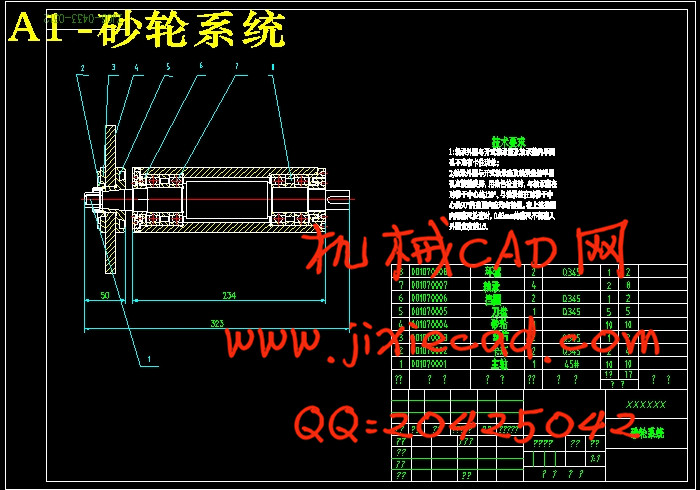

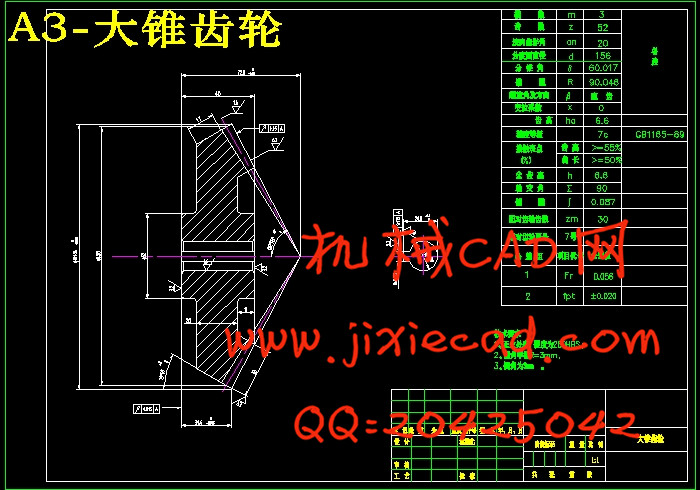

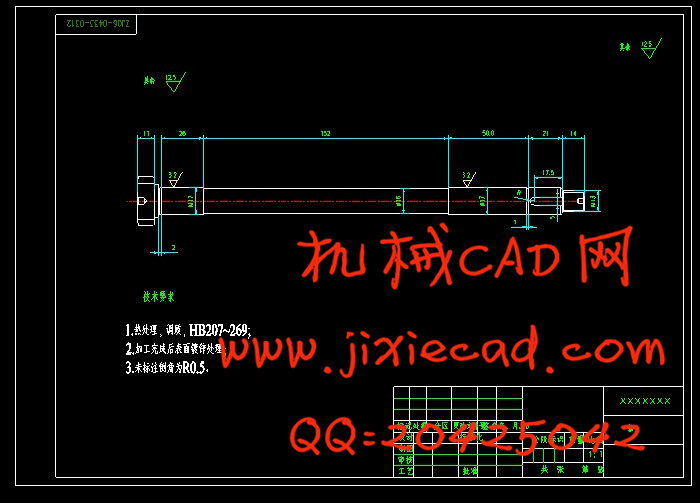

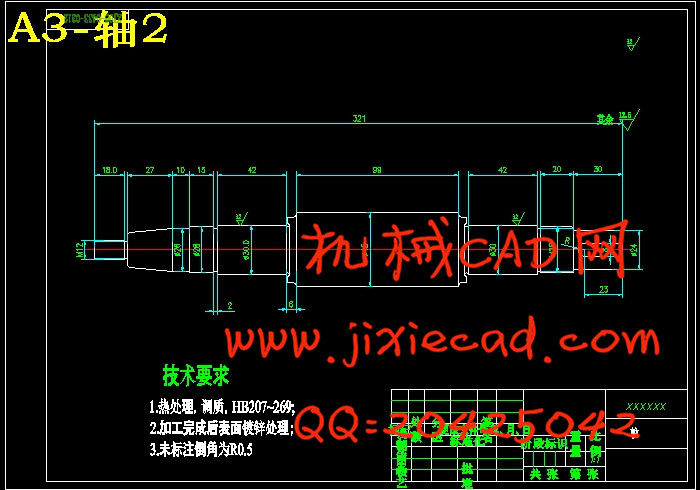

随着磨削技术的发展,磨床在加工机床中也占有相当大的比例。磨削技术及磨床在机械制造业中占有极其重要的位置。磨削技术发展很快,在机械加工中起着非常重要的作用。主轴前、后封由盘等零件均有一定程度的磨损,易产生振动,严重影响机床性能。产生磨削粗糙度达不到产品技术要求,且磨损平面有较大、明显的振纹。因而对机床主轴系统进行改造是很有价值的。本次设计主要是对M7130平面磨床进行数据分析,并进行主轴优化改造设计。主要包括平面磨床主轴系统静压轴承改装、静压轴承的有关参数选择及计算两大内容,主要研究内容是静压轴承的性能分析以及在平面磨床主轴系统中的应用。

关键字:平面磨床;高速;冷却;磨削。

Abstract

Grinding machines, for example, on the surface grinder acceptance, use, and maintenance research and draw up the statutes. According to the grinder in mechanical manufacturing performance requirements, on the surface grinding machines for specifications and acceptance, proper use and reasonable maintenance for the study and formulation. Surface grinding machine is commonly used inmetal working surface grinding machines, in machine building enterprises in heavy use. Surface grinding machine using the length of time, productivity and accuracy of high and low, largely depends on its acceptance, use, and maintenance. This fields contains the following content: 1 Introduction to various types of grinding machines 2 introduction to 3 flat surface grinder mill acceptance 4 surface grinding machine installation 5 surface grinding machines for use of surface grinding machine maintenance 6 7 surface grinding machine maintenance 8 grinding parts of surveying and mapping and lubrication chart drawing the appropriate graphics, use AutoCAD drawing software to its basic shape. With this design, are designed to explore the surface grinding machines the maximum price/performance, and for enterprises to save resources do some theory.

With the development of grinding technology, grinding machines in the machine tool also accounts for a sizeable proportion. Grinding technology and grinding machines in the machinery manufacturing industry occupies an extremely important position. Grinding technology has developed rapidly, Plays a very important role in machining. As the original machine M7130 used in production for over 30 years, Spindle before and after the closure disk and other parts have a certain degree of wear and tear, Easy to produce vibration, seriously affect the machine performance. Produce grinding roughness of less than the product technical requirements, and the wear flat greater, the obvious chatter. Thus the machine tool spindle system transformation is of great value. The design, data analysis, and the spindle to optimize the transformation design M7130 surface grinder. Include surface grinding machine spindle system hydrostatic bearing modification, the relevant parameters of the hydrostatic bearing selection and calculation of the two, The main contents of the hydrostatic bearing performance analysis, and surface grinding machine spindle system.

Keyword:surface grinde;high speed;cooling;grinding。

目录

第1章 引言 1

1.1 各类磨床简介 1

1.1.1 M1432B型万能外圆磨床简介 1

1.1.2 其他类型磨床简介 3

1.2 HZ-64 平面磨床简介 8

1.3 国内外研究状况 8

1.4 研究方法 9

1.5 论文的构成及研究内容 9

第2章 平面磨床主轴系统 10

2.1 M7130平面磨床的主要结构 10

2.2 平面磨床原理 11

2.3 主轴系统改造的结构分析及确定 12

2.3.1主要结构设计要求 12

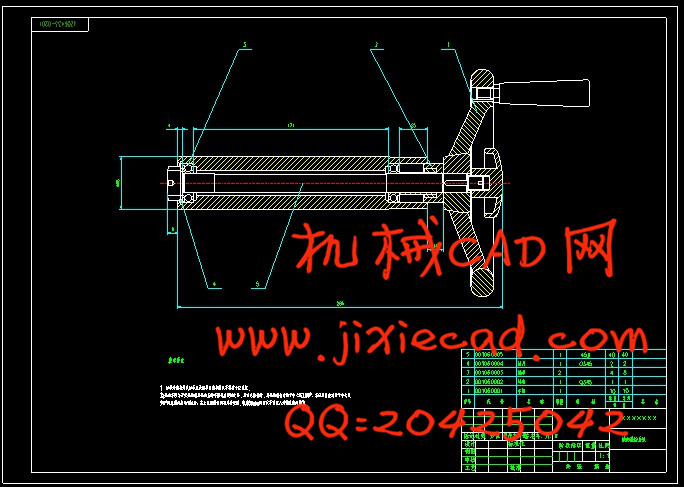

2.3.2滚动轴承的选择及校核计算 16

第3章 进给系统设计计算 19

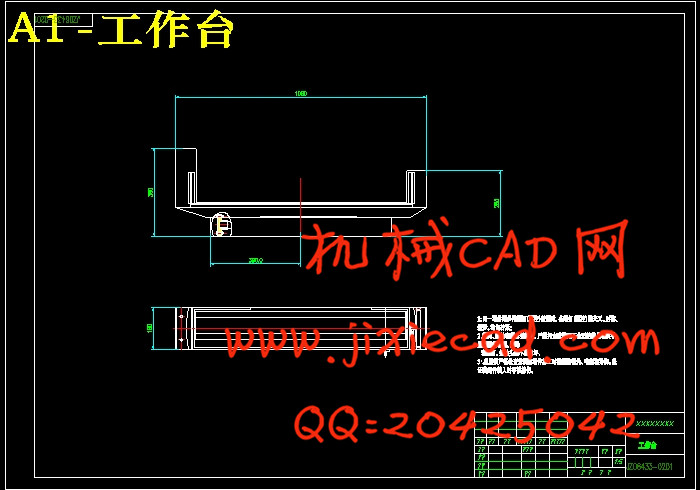

3.1工作台受力分析 19

3.2计算液压缸主要尺寸 20

3.3选择基本回路 21

3.3.1 选择调速回路 21

4.3.2 选择油源形式 21

3.3.3 选择快速运动和换向回路 22

3.3.4 选择速度换接回路 22

3.4组成液压系统 23

3.5确定液压泵的规格 24

3.5.1 计算液压泵的最大工作压力 24

3.5.2 计算液压泵的流量 24

3.6确定电动机功率 25

3.7确定油箱 25

第4章 砂轮冷却系统 27

致谢 30

参考文献 31

本设计以HZ-64和HZ-1642型平面磨床为例,对平面磨床验收、使用与维护规程的研究与制订。根据磨床在机械制造行业的性能要求,对平面磨床进行规范验收、正确使用与合理维护规程的研究与制订。平面磨床是常用的金属加工平面磨床,在机械制造企业大量使用。平面磨床使用期限的长短,生产效率和工作精度的高低,在很大程度上取决于它的验收、使用与维护情况。本课题主要包含以下内容:各类磨床简介;平面磨床简介;平面磨的验收;平面磨床的安装;平面磨床的使用规程;平面磨床的维护;平面磨床的检修;部分平面磨床零部件的测绘与润滑图表的绘制。

随着磨削技术的发展,磨床在加工机床中也占有相当大的比例。磨削技术及磨床在机械制造业中占有极其重要的位置。磨削技术发展很快,在机械加工中起着非常重要的作用。主轴前、后封由盘等零件均有一定程度的磨损,易产生振动,严重影响机床性能。产生磨削粗糙度达不到产品技术要求,且磨损平面有较大、明显的振纹。因而对机床主轴系统进行改造是很有价值的。本次设计主要是对M7130平面磨床进行数据分析,并进行主轴优化改造设计。主要包括平面磨床主轴系统静压轴承改装、静压轴承的有关参数选择及计算两大内容,主要研究内容是静压轴承的性能分析以及在平面磨床主轴系统中的应用。

关键字:平面磨床;高速;冷却;磨削。

Abstract

Grinding machines, for example, on the surface grinder acceptance, use, and maintenance research and draw up the statutes. According to the grinder in mechanical manufacturing performance requirements, on the surface grinding machines for specifications and acceptance, proper use and reasonable maintenance for the study and formulation. Surface grinding machine is commonly used inmetal working surface grinding machines, in machine building enterprises in heavy use. Surface grinding machine using the length of time, productivity and accuracy of high and low, largely depends on its acceptance, use, and maintenance. This fields contains the following content: 1 Introduction to various types of grinding machines 2 introduction to 3 flat surface grinder mill acceptance 4 surface grinding machine installation 5 surface grinding machines for use of surface grinding machine maintenance 6 7 surface grinding machine maintenance 8 grinding parts of surveying and mapping and lubrication chart drawing the appropriate graphics, use AutoCAD drawing software to its basic shape. With this design, are designed to explore the surface grinding machines the maximum price/performance, and for enterprises to save resources do some theory.

With the development of grinding technology, grinding machines in the machine tool also accounts for a sizeable proportion. Grinding technology and grinding machines in the machinery manufacturing industry occupies an extremely important position. Grinding technology has developed rapidly, Plays a very important role in machining. As the original machine M7130 used in production for over 30 years, Spindle before and after the closure disk and other parts have a certain degree of wear and tear, Easy to produce vibration, seriously affect the machine performance. Produce grinding roughness of less than the product technical requirements, and the wear flat greater, the obvious chatter. Thus the machine tool spindle system transformation is of great value. The design, data analysis, and the spindle to optimize the transformation design M7130 surface grinder. Include surface grinding machine spindle system hydrostatic bearing modification, the relevant parameters of the hydrostatic bearing selection and calculation of the two, The main contents of the hydrostatic bearing performance analysis, and surface grinding machine spindle system.

Keyword:surface grinde;high speed;cooling;grinding。

目录

第1章 引言 1

1.1 各类磨床简介 1

1.1.1 M1432B型万能外圆磨床简介 1

1.1.2 其他类型磨床简介 3

1.2 HZ-64 平面磨床简介 8

1.3 国内外研究状况 8

1.4 研究方法 9

1.5 论文的构成及研究内容 9

第2章 平面磨床主轴系统 10

2.1 M7130平面磨床的主要结构 10

2.2 平面磨床原理 11

2.3 主轴系统改造的结构分析及确定 12

2.3.1主要结构设计要求 12

2.3.2滚动轴承的选择及校核计算 16

第3章 进给系统设计计算 19

3.1工作台受力分析 19

3.2计算液压缸主要尺寸 20

3.3选择基本回路 21

3.3.1 选择调速回路 21

4.3.2 选择油源形式 21

3.3.3 选择快速运动和换向回路 22

3.3.4 选择速度换接回路 22

3.4组成液压系统 23

3.5确定液压泵的规格 24

3.5.1 计算液压泵的最大工作压力 24

3.5.2 计算液压泵的流量 24

3.6确定电动机功率 25

3.7确定油箱 25

第4章 砂轮冷却系统 27

致谢 30

参考文献 31