设计简介

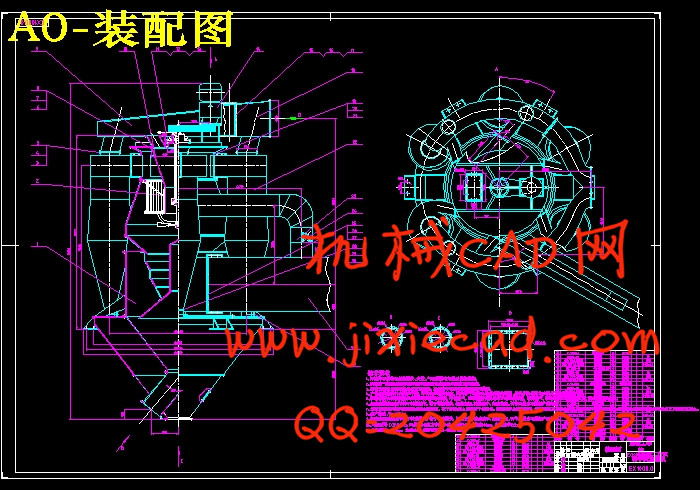

EX1000高效二次风选粉机(传动及壳体部件)设计

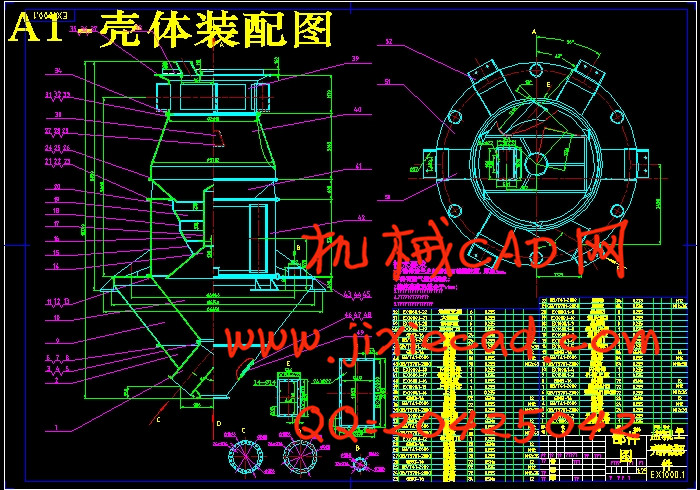

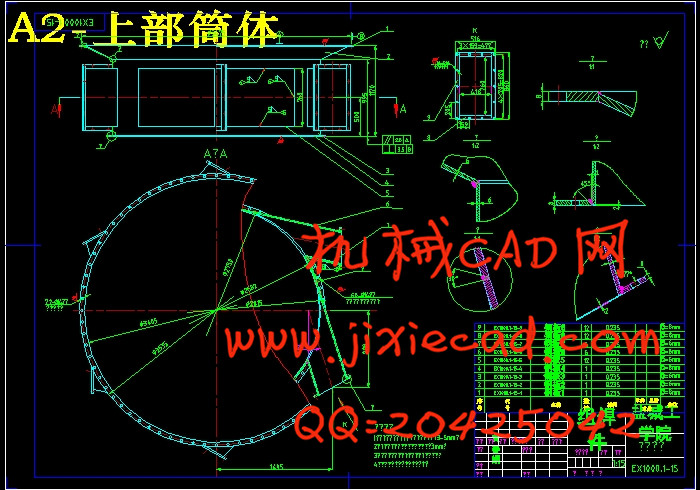

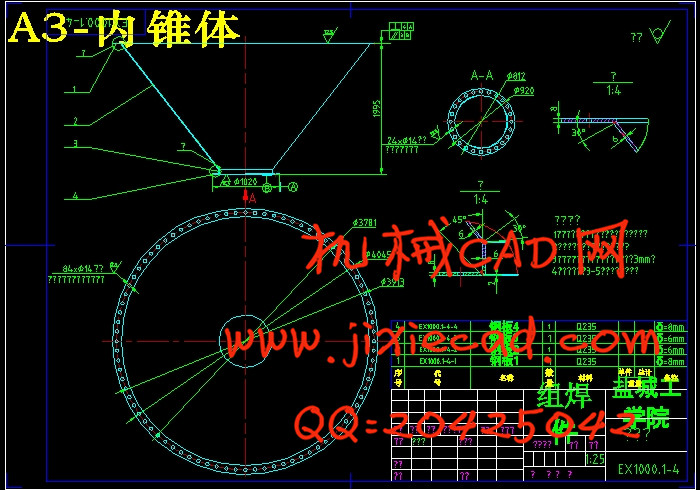

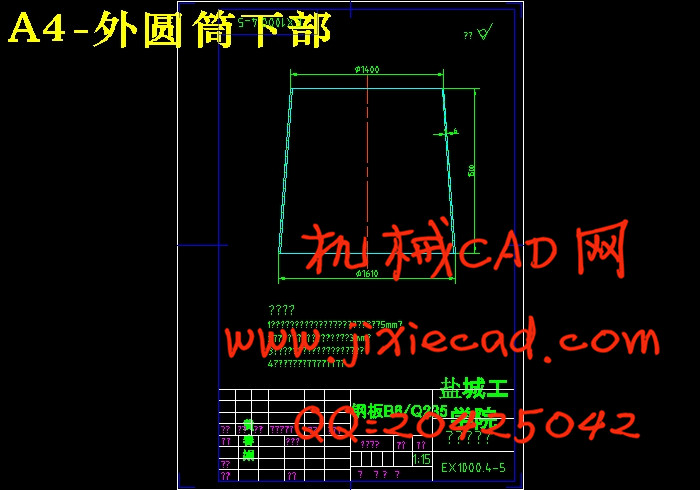

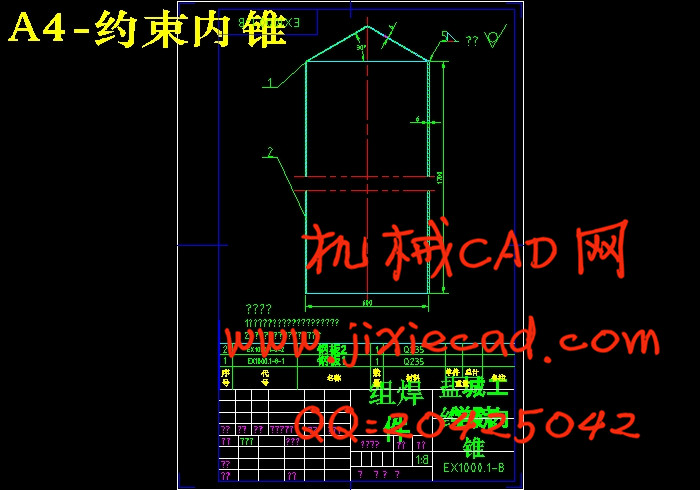

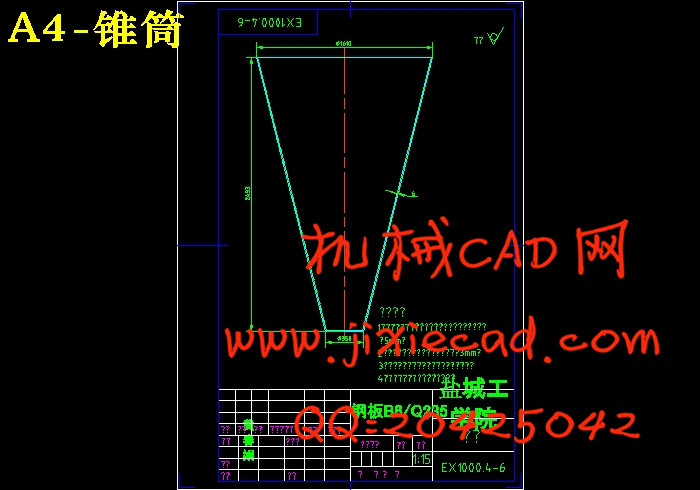

摘要:为了提高水泥粉磨系统中选粉系统的选粉效率,降低循环负荷,本课题设计了水泥圈流系统中采用的二次风选粉机。二次风选粉机是在高细转子选粉机的基础上,集悬浮分散、预分级和平面涡流分级技术于一体,专为水泥磨系统适应新标准而设计的专利产品。运用类比法,结合其他选粉机的优点,确定壳体的整体布局方案。在适当位置布置约束内锥,以稳定选粉室内的气体流场及增强二次选粉的效果;细粉分离与收集装置采用高效低阻旋风筒,提高各级细粉和超细粉的收集量。壳体的改进有利于降低系统风的阻力,提高选粉效率。选粉机采用整体紧凑设计,大大降低了占据空间,且大大提高了选粉效率。机体工作运行平稳,安装维修方便。选粉机设计的主要特点是采用二次风结构,即在选粉机进风管道上增设一个旁路支风管,作为二次风管,并设置一个机外调节的风阀,二次风气流切向进入选粉室内。这样可以有效地控制上升风速,改变和控制细度。二次风的导入,对粗颗粒能进行二次切割,改善成品的颗粒级配。

关键词:二次风 ;高效选粉机 ;类比法 ;旋风筒;选粉效率;约束内锥

Design of EX1000 high efficiency powder-selecting machine with secondary air (transmission and shell parts)

Abstract:In order to improve the powder-selecting efficiency of the powder-selecting system in cement grinding system, reduce circulation load, the powder-selecting machine with secondary air used in the cement loop system is designed. The powder-selecting machine with secondary air, which is combined the aerosol disperse, the pre-gradation with the plane vortex classified technology in a body, is specially designed to adapt to the new standard for cement grinding system in the foundation of the high thin rotor powder selecting machine. Adopting analogy method and combining the advantage of others,the overall arrangement scheme of the shell is determined. In order to stable the flow field in powder-selecting room and strengthen the effect of secondary powder-selecting, constrained inner cone is arranged in the appropriate position. The thin powder separation and the collecting device use the high efficiency coclone with low resistivity, thus the collection property of the fine dust and the ultra fine dust is enhanced. The improvement of the shell is of benefit to reduce the resistance of the system wind and improve the powder–selecting efficiency. The powder-selecting machine is arranged rationally and compactly, occupying little space and improving powder-selecting efficiency greatly. It is the main characteristic that the structure with secondary air is adopted in the powder-selecting machine. By way of secondary air duct, an additional bypass tuyere is set on air-supply line of the powder-selecting machine. In addition, the wind valve for adjustment is established outside the machine, so that secondary air currents flow into power selecting room in circumferential direction. This may be able effectively to control the rising wind speed, change and control fineness. Because of inducting secondary air, the coarse particles can be selected secondly, and grain grading of the finished product is improved.

Key words:secondary air; high efficiency separator; analogy method; cyclone; powder-selecting efficiency; constrainted inner cone

目 录

1 前言………………………………………………………………………………………1

1.1 选粉机的发展历史……………………………………………………………………1

1.1.1 第一代选粉机………………………………………………………………………1

1.1.2 第二代选粉机…………………………………………………………………………1

1.1.3 第三代选粉机…………………………………………………………………………1

1.2 选粉机技术发展状况 …………………………………………………………………1

1.3 选粉机发展趋势………………………………………………………………………2

2 总体方案论证……………………………………………………………………………3

2.1课题的来源、内容和技术要求………………………………………………………3

2.1 课题设计的工作原理………………………………………………………3

2.2 课题设计的结构特点………………………………………………………3

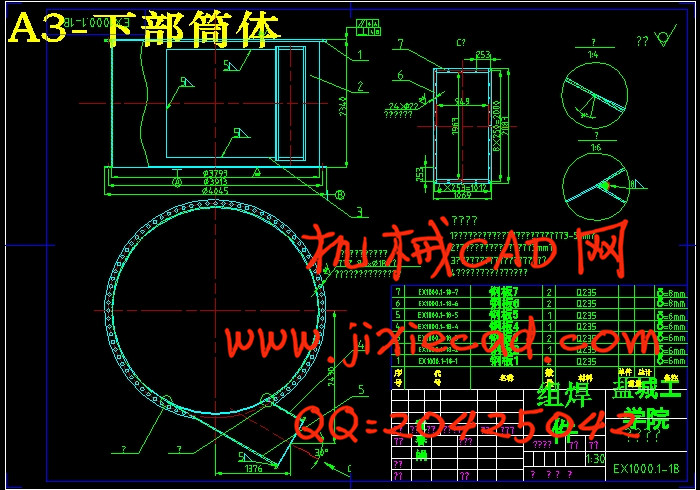

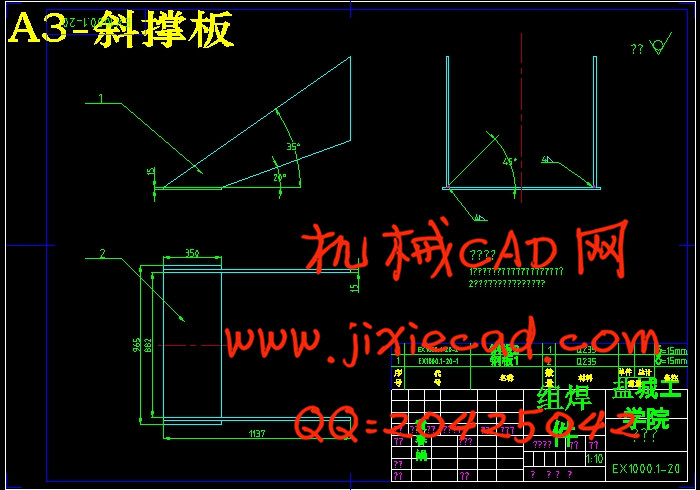

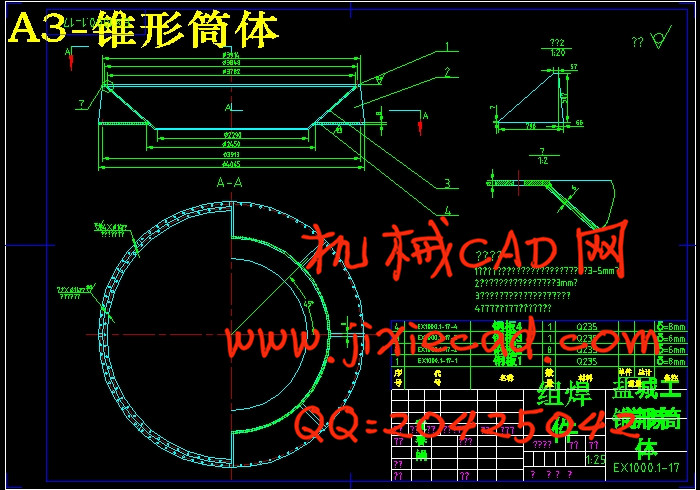

3 具体设计说明……………………………………………………………………………7

3.1 主要技术参数计算……………………………………………………………………7

3.1.1 主要工艺尺寸………………………………………………………………………7

3.1.2 生产能力……………………………………………………………………………7

3.1.3 选粉室直径…………………………………………………………………………7

3.1.4 风量…………………………………………………………………………………8

3.1.5 风机选型……………………………………………………………………………8

3.1.6 主轴转速……………………………………………………………………………8

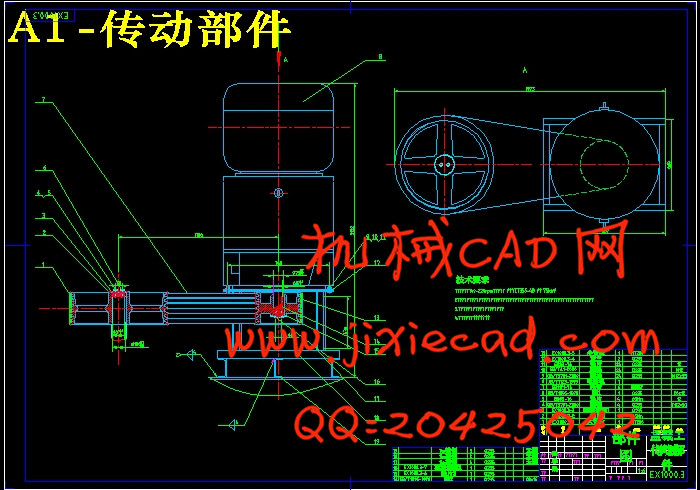

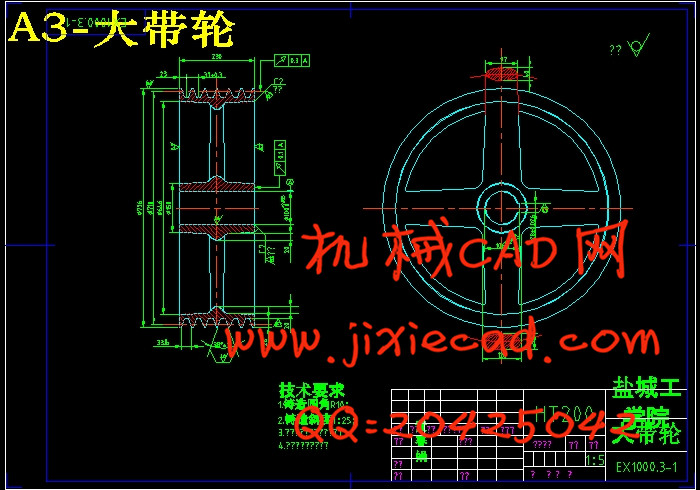

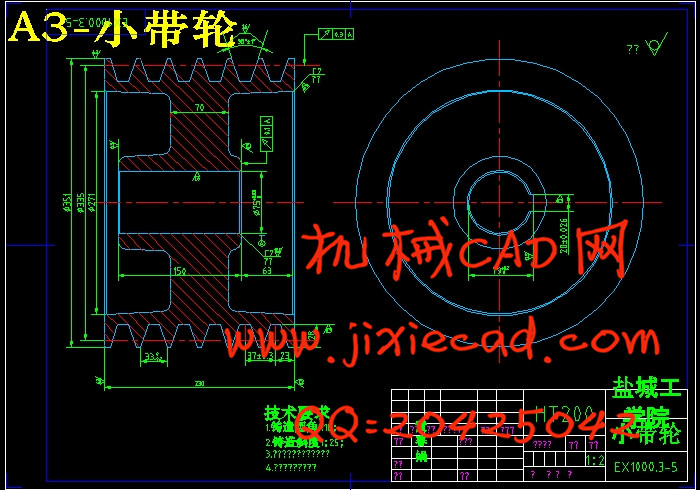

3.2 传动部分设计…………………………………………………………………………8

3.2.1 电机的选择…………………………………………………………………………8

3.2.2 带的设计计算………………………………………………………………………9

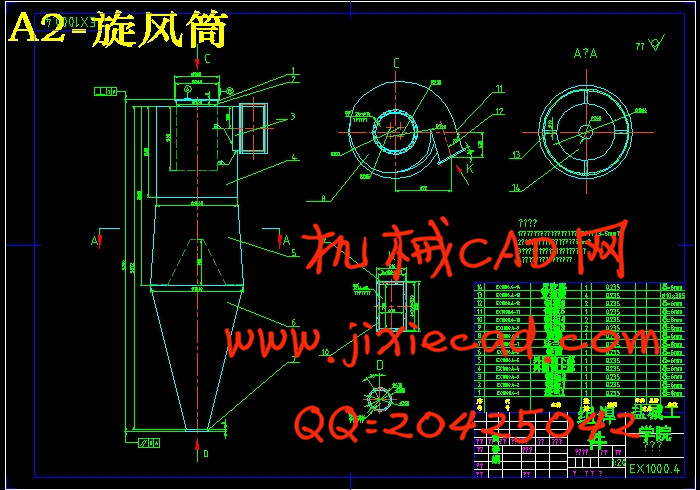

3.3 旋风筒设计……………………………………………………………………………12

3.3.1 旋风筒的收尘工作原理……………………………………………………………12

3.3.2 旋风筒的尺寸计算…………………………………………………………………13

3.4 滴流装置………………………………………………………………………………14

3.5 内衬……………………………………………………………………………………15

3.6 螺栓组连接的设计……………………………………………………………………16

3.6.1 螺栓组连接的结构设计……………………………………………………………16

3.6.2 螺栓组连接的受力分析……………………………………………………………17

3.7 螺纹连接的强度计算…………………………………………………………………18

3.7.1 螺纹连接的失效形式………………………………………………………………18

3.7.2 螺栓连接的强度计算………………………………………………………………18

3.8 焊接工艺……………………………………………………………………………20

3.8.1 焊接工艺的制订原则………………………………………………………………20

3.8.2 焊接方法的选择……………………………………………………………………20

3.8.3 焊接材料的选择……………………………………………………………………20

3.8.4 焊接工艺参数的选择………………………………………………………………20

3.8.5 焊前预热及焊后热处理……………………………………………………………21

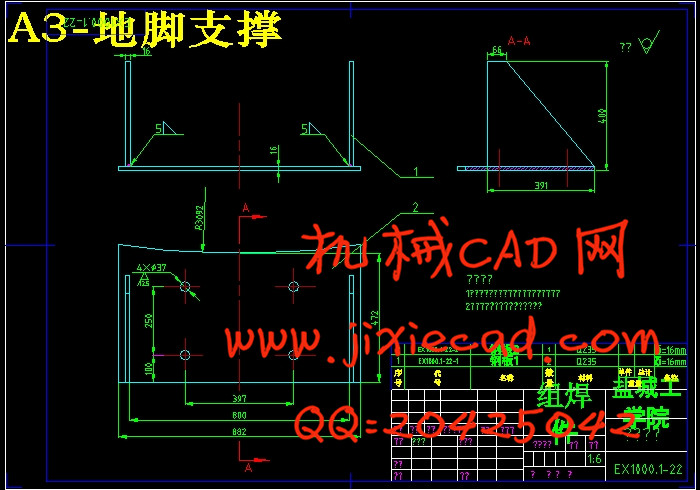

4 操作、安装、维护及检修………………………………………………………………23

4.1 操作……………………………………………………………………………………23

4.2 安装……………………………………………………………………………………23

4.3 维护……………………………………………………………………………………23

4.4 检修……………………………………………………………………………………24

5 预期效果…………………………………………………………………………………25

6 结论………………………………………………………………………………………26

参考文献……………………………………………………………………………………27

致谢…………………………………………………………………………………………28

附录…………………………………………………………………………………………29

摘要:为了提高水泥粉磨系统中选粉系统的选粉效率,降低循环负荷,本课题设计了水泥圈流系统中采用的二次风选粉机。二次风选粉机是在高细转子选粉机的基础上,集悬浮分散、预分级和平面涡流分级技术于一体,专为水泥磨系统适应新标准而设计的专利产品。运用类比法,结合其他选粉机的优点,确定壳体的整体布局方案。在适当位置布置约束内锥,以稳定选粉室内的气体流场及增强二次选粉的效果;细粉分离与收集装置采用高效低阻旋风筒,提高各级细粉和超细粉的收集量。壳体的改进有利于降低系统风的阻力,提高选粉效率。选粉机采用整体紧凑设计,大大降低了占据空间,且大大提高了选粉效率。机体工作运行平稳,安装维修方便。选粉机设计的主要特点是采用二次风结构,即在选粉机进风管道上增设一个旁路支风管,作为二次风管,并设置一个机外调节的风阀,二次风气流切向进入选粉室内。这样可以有效地控制上升风速,改变和控制细度。二次风的导入,对粗颗粒能进行二次切割,改善成品的颗粒级配。

关键词:二次风 ;高效选粉机 ;类比法 ;旋风筒;选粉效率;约束内锥

Design of EX1000 high efficiency powder-selecting machine with secondary air (transmission and shell parts)

Abstract:In order to improve the powder-selecting efficiency of the powder-selecting system in cement grinding system, reduce circulation load, the powder-selecting machine with secondary air used in the cement loop system is designed. The powder-selecting machine with secondary air, which is combined the aerosol disperse, the pre-gradation with the plane vortex classified technology in a body, is specially designed to adapt to the new standard for cement grinding system in the foundation of the high thin rotor powder selecting machine. Adopting analogy method and combining the advantage of others,the overall arrangement scheme of the shell is determined. In order to stable the flow field in powder-selecting room and strengthen the effect of secondary powder-selecting, constrained inner cone is arranged in the appropriate position. The thin powder separation and the collecting device use the high efficiency coclone with low resistivity, thus the collection property of the fine dust and the ultra fine dust is enhanced. The improvement of the shell is of benefit to reduce the resistance of the system wind and improve the powder–selecting efficiency. The powder-selecting machine is arranged rationally and compactly, occupying little space and improving powder-selecting efficiency greatly. It is the main characteristic that the structure with secondary air is adopted in the powder-selecting machine. By way of secondary air duct, an additional bypass tuyere is set on air-supply line of the powder-selecting machine. In addition, the wind valve for adjustment is established outside the machine, so that secondary air currents flow into power selecting room in circumferential direction. This may be able effectively to control the rising wind speed, change and control fineness. Because of inducting secondary air, the coarse particles can be selected secondly, and grain grading of the finished product is improved.

Key words:secondary air; high efficiency separator; analogy method; cyclone; powder-selecting efficiency; constrainted inner cone

目 录

1 前言………………………………………………………………………………………1

1.1 选粉机的发展历史……………………………………………………………………1

1.1.1 第一代选粉机………………………………………………………………………1

1.1.2 第二代选粉机…………………………………………………………………………1

1.1.3 第三代选粉机…………………………………………………………………………1

1.2 选粉机技术发展状况 …………………………………………………………………1

1.3 选粉机发展趋势………………………………………………………………………2

2 总体方案论证……………………………………………………………………………3

2.1课题的来源、内容和技术要求………………………………………………………3

2.1 课题设计的工作原理………………………………………………………3

2.2 课题设计的结构特点………………………………………………………3

3 具体设计说明……………………………………………………………………………7

3.1 主要技术参数计算……………………………………………………………………7

3.1.1 主要工艺尺寸………………………………………………………………………7

3.1.2 生产能力……………………………………………………………………………7

3.1.3 选粉室直径…………………………………………………………………………7

3.1.4 风量…………………………………………………………………………………8

3.1.5 风机选型……………………………………………………………………………8

3.1.6 主轴转速……………………………………………………………………………8

3.2 传动部分设计…………………………………………………………………………8

3.2.1 电机的选择…………………………………………………………………………8

3.2.2 带的设计计算………………………………………………………………………9

3.3 旋风筒设计……………………………………………………………………………12

3.3.1 旋风筒的收尘工作原理……………………………………………………………12

3.3.2 旋风筒的尺寸计算…………………………………………………………………13

3.4 滴流装置………………………………………………………………………………14

3.5 内衬……………………………………………………………………………………15

3.6 螺栓组连接的设计……………………………………………………………………16

3.6.1 螺栓组连接的结构设计……………………………………………………………16

3.6.2 螺栓组连接的受力分析……………………………………………………………17

3.7 螺纹连接的强度计算…………………………………………………………………18

3.7.1 螺纹连接的失效形式………………………………………………………………18

3.7.2 螺栓连接的强度计算………………………………………………………………18

3.8 焊接工艺……………………………………………………………………………20

3.8.1 焊接工艺的制订原则………………………………………………………………20

3.8.2 焊接方法的选择……………………………………………………………………20

3.8.3 焊接材料的选择……………………………………………………………………20

3.8.4 焊接工艺参数的选择………………………………………………………………20

3.8.5 焊前预热及焊后热处理……………………………………………………………21

4 操作、安装、维护及检修………………………………………………………………23

4.1 操作……………………………………………………………………………………23

4.2 安装……………………………………………………………………………………23

4.3 维护……………………………………………………………………………………23

4.4 检修……………………………………………………………………………………24

5 预期效果…………………………………………………………………………………25

6 结论………………………………………………………………………………………26

参考文献……………………………………………………………………………………27

致谢…………………………………………………………………………………………28

附录…………………………………………………………………………………………29