设计简介

摘要

热定型机(拉幅机)是利用热空气对纺织物,塑料等进行干燥和整理并使之定型的一种设备。随着中国热定型机产业发展,它已经慢慢地走到了瓶颈期,很出问题都悄然出现,如产业结构不合理、产业集中于劳动力密集型产品;技术密集型产品明显落后于发达工业国家;生产要素决定性作用正在削弱;产业能源资源消耗大、产出率低,对环境的污染严重,自然环境的破坏也极为严重;企业总体规模偏小、技术创新能力薄弱、管理水平落后等。其中,技术创新能力是相当的薄弱的,所以要改变热定型机发展的趋势,技术创新是重中之重。从而,本文着重于热定型机的设计,关于渔网热定型机的设计。

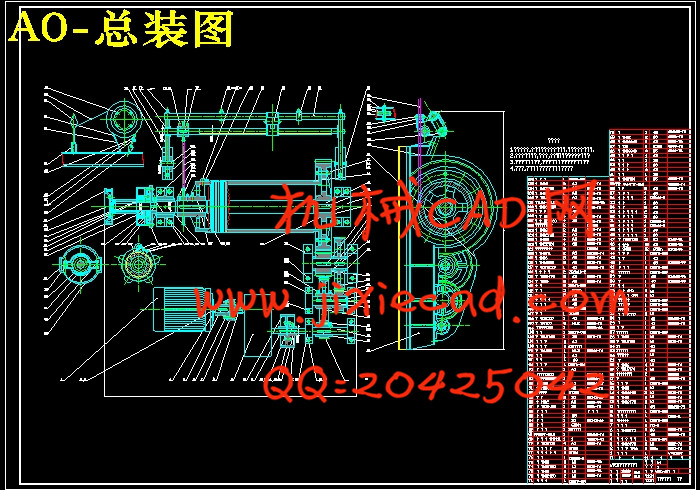

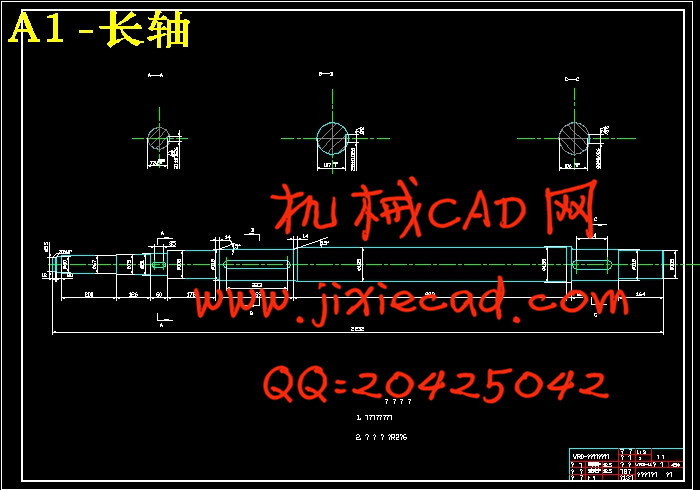

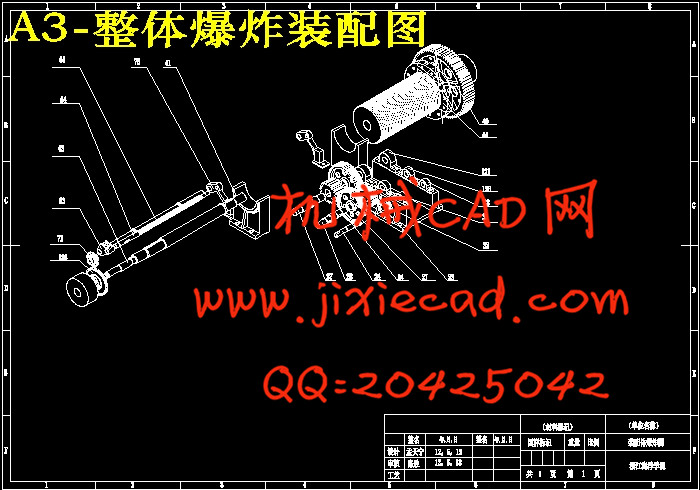

它由动力部分,传动机构,拉伸机构和热定型设备四部分组成。动力部分选择尽可能大的扭矩来满足传递,同时可以根据需定型的网线的粗细,材料来选择电动机的转速。传动机构由电动机,联轴器,减速机,滚筒和其他组件构成的,传动路线:1电动机——2剪切削联轴器——3减速器——4主轴——5链传动。拉伸机构是由固定架,中间架,桁架,滑轮组和固定渔网的挂网片组成,桁架受到从滑轮组上传来的拉力即渔网张紧时的拉力。最后即热定型部分,是在温度为98°的热定型池中完成渔网热定型的。

本文主要设计渔网定型机的传动部分。我使用Autocad和solidworks来设计一些定型机中的主要零件,从而减小工程设计的难度,提高工作效率。并利用solidworks的仿真功能(simulation)来模拟渔网热定型机的传动过程,使得整个运行过程更加直观。

关键词:齿轮传动;轴;渔网拉伸;热定型;减速器;solidworks

Abstract

Net heating machine, also be called tenter, which is a device that makes use of heating air to dry and order textile and plastic and things. With the development of Chinese net heating machine industry, it comes into the decreasing time, with some big problems appearing behind their backs, such as unreasonable industrial construction, labor intensive product concentrates on industry, something technical far behind with developed countries, high energy consumption, serious environment pollution which gives rise to the lack of natural resources, small scale companies, low creativity and management level. During this, technical creativity is extremely low which needs to be paid more attention, in order to change this, creative design has to play a more indispensable role. This paper is about fishing net heat setting machine design, which consists of driving force section,driving gear, stretching and heat-setting device. Driving force section selects the torque as much as we can get to meet delivery and at the same time, the rotated speed of the motor that we choose depends on the net string’s size and material. Driving gear is made up of motor, coupling, reducer, roller and the other components. The driving route : 1 motor - 2 Coupling - 3 reducer - 4 Spindle - 5 chain drive. Stretching includes fixation, the middle frame, truss, pulley block and the peg to a fixed fishing net mesh equipment, this pulling force got from pulley block which receives from truss equals the pulling force when fishing net tightens. Heat setting device is equipped with a heating device shaped pool, setting the temperature about 98 ℃. And this project is mainly about the design of driving gear. In this design, I use Autocad and solidworks software to design the major components of this device, which greatly reduces the engineering labor, improving work efficiency.

Key word:gearing;Shaft;net tensile;heat-setting;reducer; solidworks

目录

前言 1

第1章 概述 2

1.1 热定型机的简述 2

1.2 主要机械设计内容 3

第2章 方案设计及说明 4

2.1 机械传动设计 4

2.2 整体设计方案示意说明 5

第3章 结构零件的设计 7

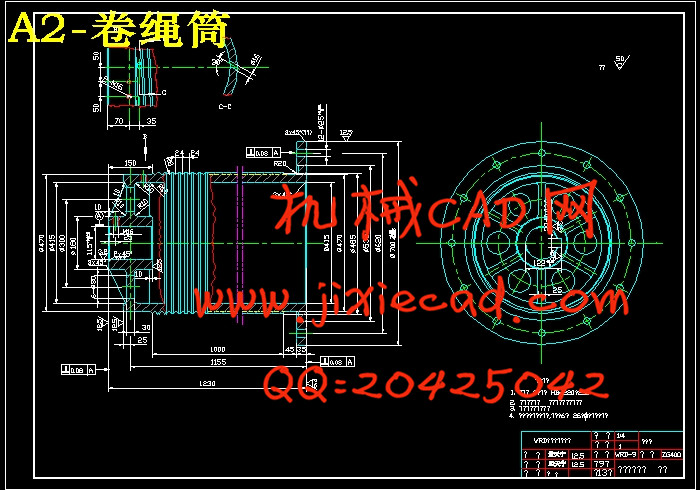

3.1 钢丝绳的计算选择及卷筒设计 7

3.2 电动机传动效率的确定 9

3.2.1 电动机的选择 10

3.2.2 传动比分配及运动参数确定 10

3.2.3 各个轴参数的计算 11

3.2.4 减速器的选择 12

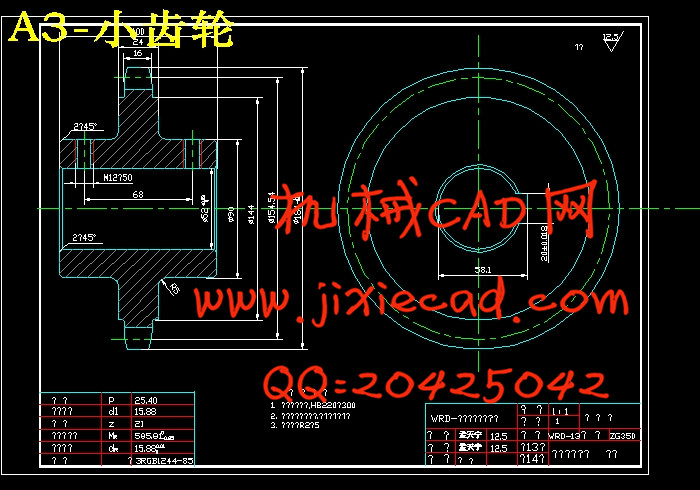

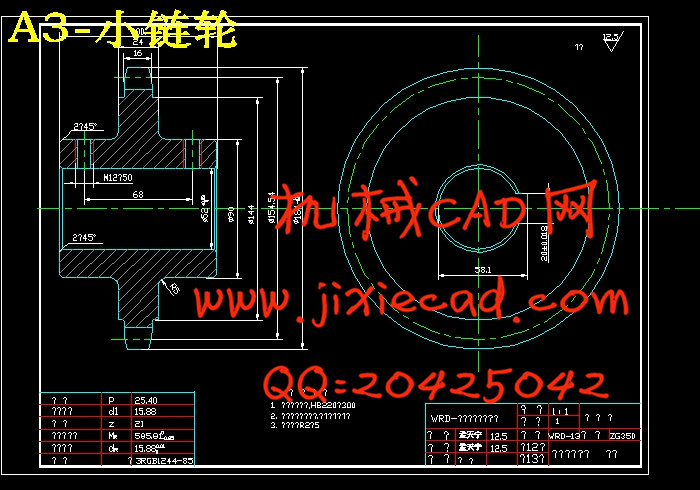

3.3 齿轮的设计 13

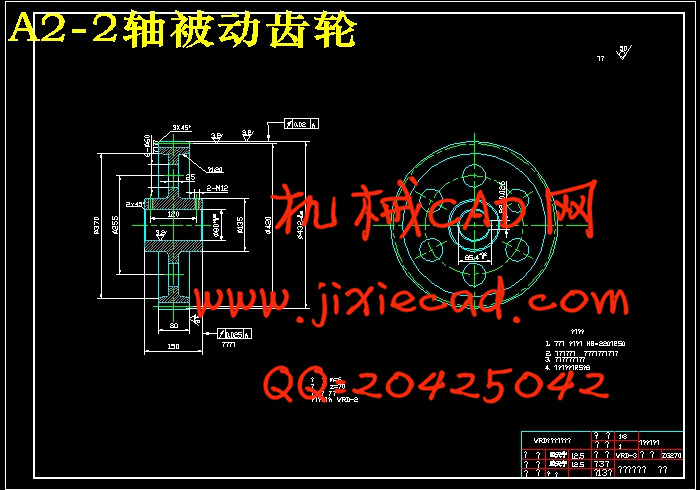

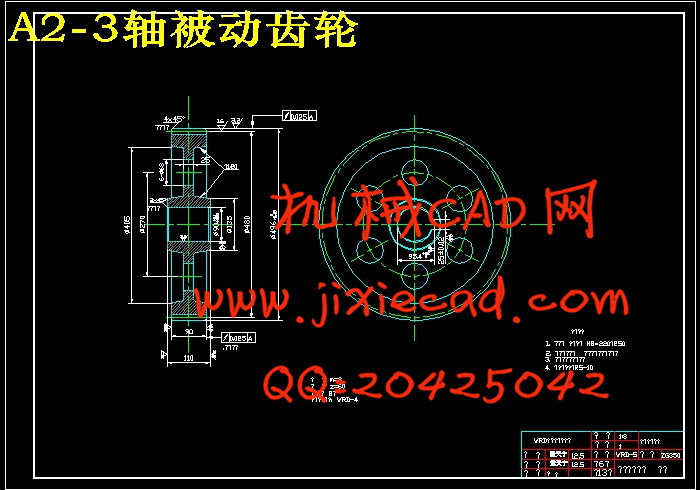

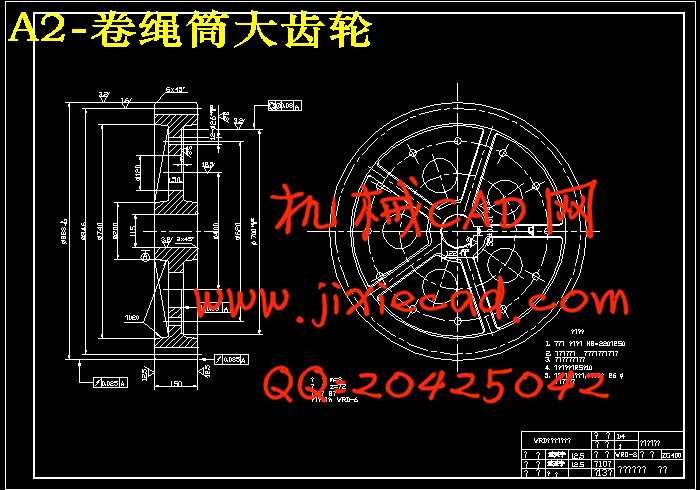

3.3.1 齿轮各尺寸参数的计算确定 13

3.3.2 各对齿轮的强度及重合度的校核 15

3.4 轴结构设计与强度校核 20

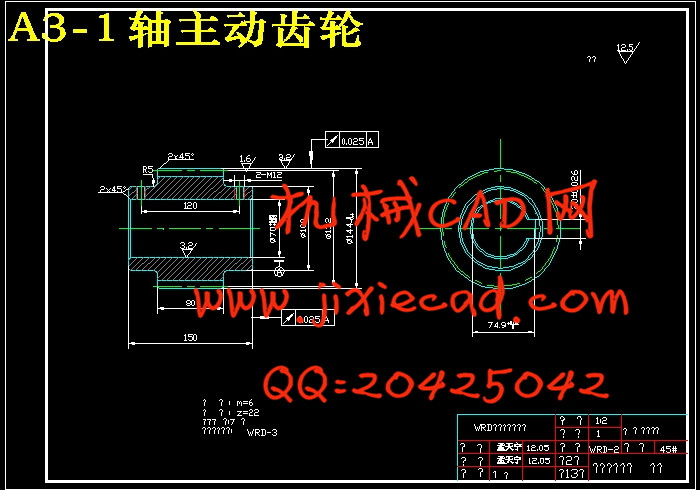

3.4.1 I轴结构设计 20

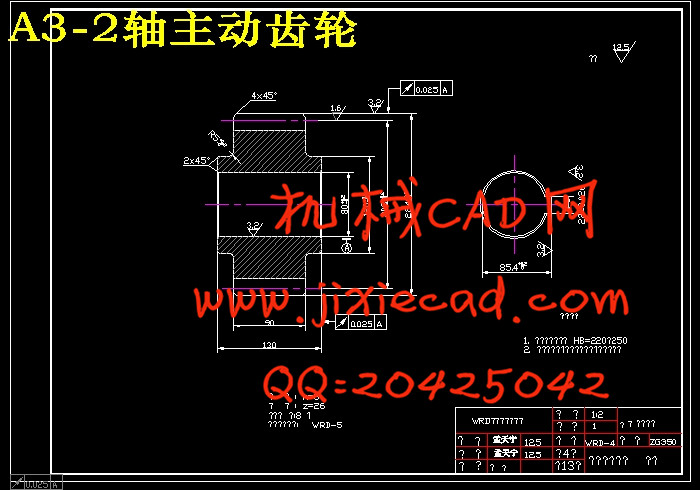

3.4.2 II轴结构设计与强度校核 24

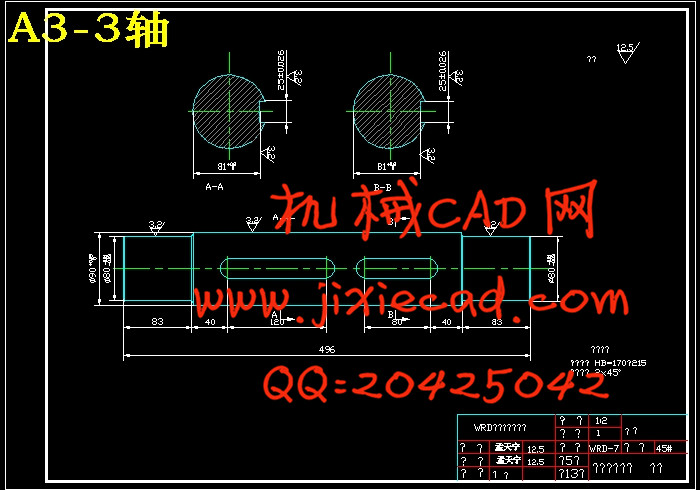

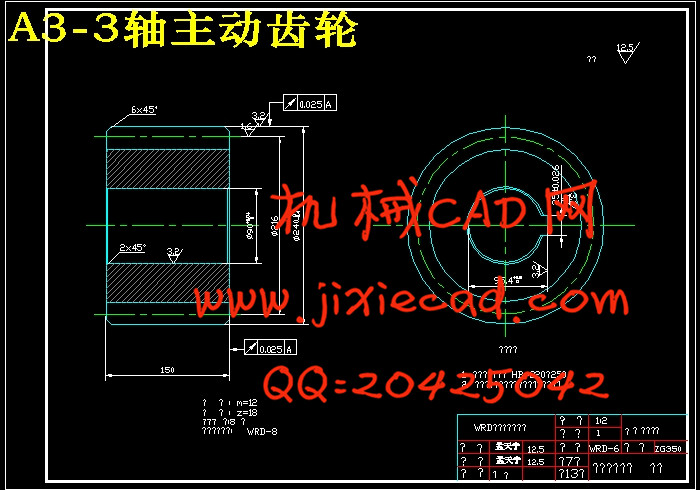

3.4.3 III轴结构设计与强度计算 27

3.5 各齿轮轴上轴承的选用及校核 30

3.6 制动器的选择 31

3.7 链传动 32

3.8 系统润滑及保养设计说明 35

第4章 运动仿真的应用 37

4.1 仿真的概念 37

4.2 运动仿真软件的分类 37

4.3 仿真的应用与发展前景 37

4.4 solidworks仿真功能简介 38

4.5 热定型机的仿真过程 38

结论 41

致谢 42

参考文献 43

热定型机(拉幅机)是利用热空气对纺织物,塑料等进行干燥和整理并使之定型的一种设备。随着中国热定型机产业发展,它已经慢慢地走到了瓶颈期,很出问题都悄然出现,如产业结构不合理、产业集中于劳动力密集型产品;技术密集型产品明显落后于发达工业国家;生产要素决定性作用正在削弱;产业能源资源消耗大、产出率低,对环境的污染严重,自然环境的破坏也极为严重;企业总体规模偏小、技术创新能力薄弱、管理水平落后等。其中,技术创新能力是相当的薄弱的,所以要改变热定型机发展的趋势,技术创新是重中之重。从而,本文着重于热定型机的设计,关于渔网热定型机的设计。

它由动力部分,传动机构,拉伸机构和热定型设备四部分组成。动力部分选择尽可能大的扭矩来满足传递,同时可以根据需定型的网线的粗细,材料来选择电动机的转速。传动机构由电动机,联轴器,减速机,滚筒和其他组件构成的,传动路线:1电动机——2剪切削联轴器——3减速器——4主轴——5链传动。拉伸机构是由固定架,中间架,桁架,滑轮组和固定渔网的挂网片组成,桁架受到从滑轮组上传来的拉力即渔网张紧时的拉力。最后即热定型部分,是在温度为98°的热定型池中完成渔网热定型的。

本文主要设计渔网定型机的传动部分。我使用Autocad和solidworks来设计一些定型机中的主要零件,从而减小工程设计的难度,提高工作效率。并利用solidworks的仿真功能(simulation)来模拟渔网热定型机的传动过程,使得整个运行过程更加直观。

关键词:齿轮传动;轴;渔网拉伸;热定型;减速器;solidworks

Abstract

Net heating machine, also be called tenter, which is a device that makes use of heating air to dry and order textile and plastic and things. With the development of Chinese net heating machine industry, it comes into the decreasing time, with some big problems appearing behind their backs, such as unreasonable industrial construction, labor intensive product concentrates on industry, something technical far behind with developed countries, high energy consumption, serious environment pollution which gives rise to the lack of natural resources, small scale companies, low creativity and management level. During this, technical creativity is extremely low which needs to be paid more attention, in order to change this, creative design has to play a more indispensable role. This paper is about fishing net heat setting machine design, which consists of driving force section,driving gear, stretching and heat-setting device. Driving force section selects the torque as much as we can get to meet delivery and at the same time, the rotated speed of the motor that we choose depends on the net string’s size and material. Driving gear is made up of motor, coupling, reducer, roller and the other components. The driving route : 1 motor - 2 Coupling - 3 reducer - 4 Spindle - 5 chain drive. Stretching includes fixation, the middle frame, truss, pulley block and the peg to a fixed fishing net mesh equipment, this pulling force got from pulley block which receives from truss equals the pulling force when fishing net tightens. Heat setting device is equipped with a heating device shaped pool, setting the temperature about 98 ℃. And this project is mainly about the design of driving gear. In this design, I use Autocad and solidworks software to design the major components of this device, which greatly reduces the engineering labor, improving work efficiency.

Key word:gearing;Shaft;net tensile;heat-setting;reducer; solidworks

目录

前言 1

第1章 概述 2

1.1 热定型机的简述 2

1.2 主要机械设计内容 3

第2章 方案设计及说明 4

2.1 机械传动设计 4

2.2 整体设计方案示意说明 5

第3章 结构零件的设计 7

3.1 钢丝绳的计算选择及卷筒设计 7

3.2 电动机传动效率的确定 9

3.2.1 电动机的选择 10

3.2.2 传动比分配及运动参数确定 10

3.2.3 各个轴参数的计算 11

3.2.4 减速器的选择 12

3.3 齿轮的设计 13

3.3.1 齿轮各尺寸参数的计算确定 13

3.3.2 各对齿轮的强度及重合度的校核 15

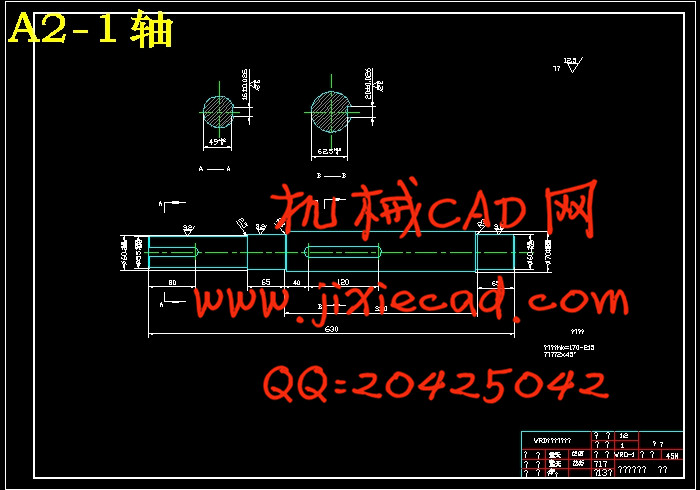

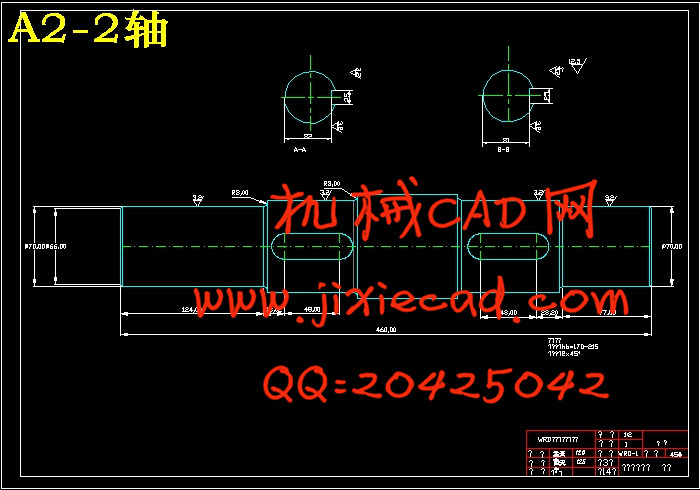

3.4 轴结构设计与强度校核 20

3.4.1 I轴结构设计 20

3.4.2 II轴结构设计与强度校核 24

3.4.3 III轴结构设计与强度计算 27

3.5 各齿轮轴上轴承的选用及校核 30

3.6 制动器的选择 31

3.7 链传动 32

3.8 系统润滑及保养设计说明 35

第4章 运动仿真的应用 37

4.1 仿真的概念 37

4.2 运动仿真软件的分类 37

4.3 仿真的应用与发展前景 37

4.4 solidworks仿真功能简介 38

4.5 热定型机的仿真过程 38

结论 41

致谢 42

参考文献 43